|

|

|

|

|

|

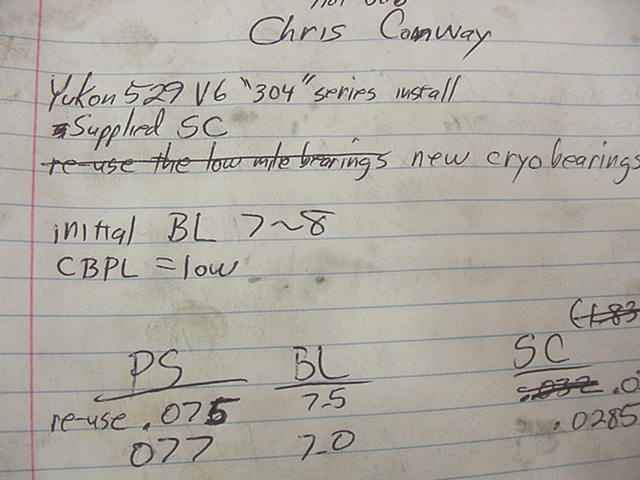

Here's a shot of Chris's nice rig and here's the specs....

|

|

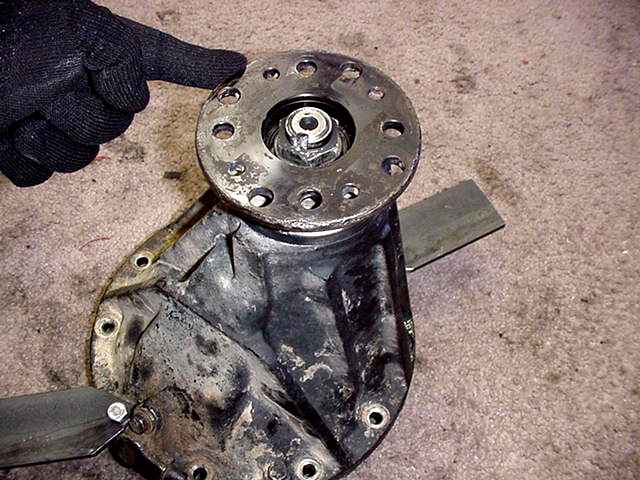

Chris did a nice job of securely packing the 3rd. |

|

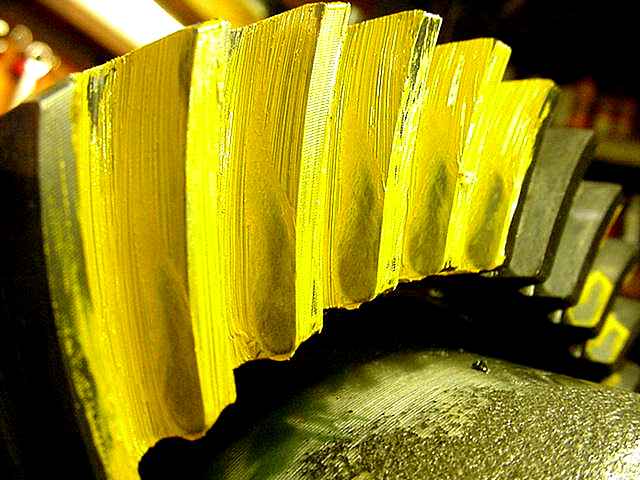

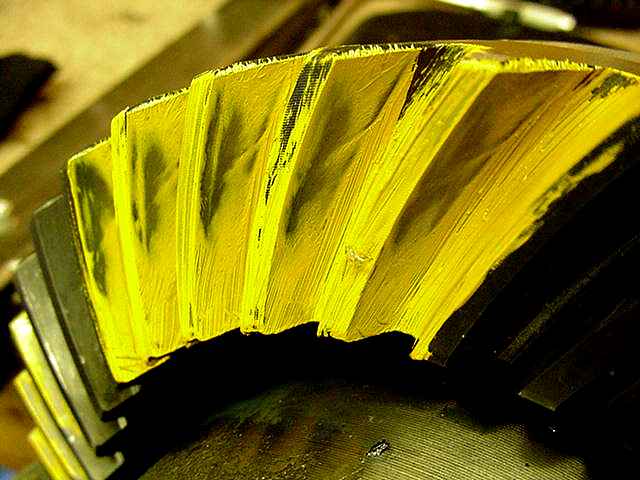

Here's a couple pics of the gears...he heard some noises from the gears and decided to do an oil change and found metal splinters in the oil. These gears were supposedly cryo and heat treated. |

|

This is the best detail that I can photograph and it seems like the gears were made of glass. Yukon gears are good gears and I don't believe they had anything to do with this failure mode. |

|

The brittle nature of these shards of metal suggests that the cryo process was done improperly and tremendous stresses were introduced into the metal.................perhaps by dropping the gears into the boiling liquid nitrogen? |

|

Initial backlash was about 7~8 thousandths which is good....some CBPL was there but it was still low. |

|

The pattern seemed a bit heavy on the toe end. |

|

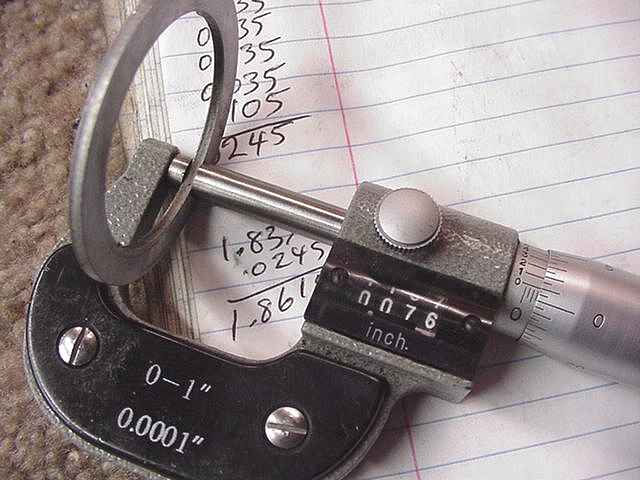

Coast was a bit high and to the heel. The correct pinion shim was used (.076") so I'm not quite sure why the pattern isn't better than this. |

|

I took another pattern reading on the opposite side of the ring gear and results were identical. |

|

coast |

|

The bluish colored oil is Redline Lightweight Shockproof gear lube. This pic does not do it justice. I don't believe there was any water in it as it was not whitish or foamy. That shockproof oil is unusual stuff. |

|

This is the V6 Yukon gear that was supposedly heat treated also. I see no signs of heat treating which shows up as bluish dis-colorization marks near thin spots....not a one to be found. A perfectly clean gear. |

|

I call this the "304" series Yukon gear...where they actually come from is anyone's guess.... I have set many of these up in the past and they do set well. |

|

Nothing special to say here before dis-assembling. PPL was low (expected) but that seems to be the general case when pinion bearings are involved. |

|

The light duty press easily pushed the old pinion out. |

|

The inner pinion bearing comes off nicely with the right bearing splitter. |

|

The pinion shim that the shop used was an expected shim for this gear set. |

|

As expected, the stronger pinion teeth showed little damage compared to the smaller ring teeth. |

|

Chris sent me an identical brand new Yukon 529 gearset to be installed....there was no time for him to have it cryo or heat treated which is probably good because who knows what kind of internal damage might have been done. |

|

Red Loctite and 75 ft/lbs. |

|

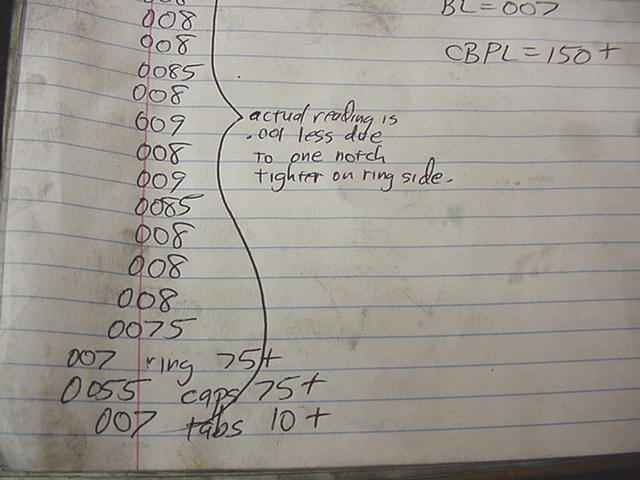

I used all new bearings on this install....these were cryo treated properly from a local operation to me called Cryogenics International. These bearings should wear about 3~5 times longer than regular bearings. This is an amazing improvement in bearing life. Noise and heat is also reduced. Carrier bearing pre-loads and pinion pre-loads stay in spec for much longer periods of time. |

|

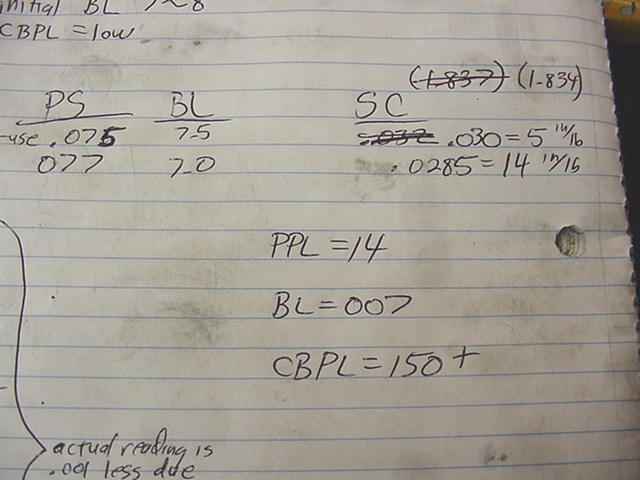

Not shown but the first time I tried a .075 pinion depth shim and it appeared ever so slightly shallow. Now I am using a .077" shim.... |

|

The solid collar was re-installed and set for 14 in/lb of PPL. |

|

Beautiful pattern....a bit slight towards the heel but that is where it stubbornly stayed even with a minimal BL of 007. |

|

coast |

|

I did not paint these teeth directly....the pinion actually did the painting. I always look at these secondary paints as it can sometimes show the pattern in a different light. |

|

coast |

|

Ready for the trip back to CA. |

|

Date coded with specs used. |

|

......................................................... |

|

Notes I took during the install. |

|

......................................................... |

|

................................................... |

|