|

Chris was on THE STEP on the Charlotte Gap Trail, Tucson AZ when the front went bang!

|

|

|

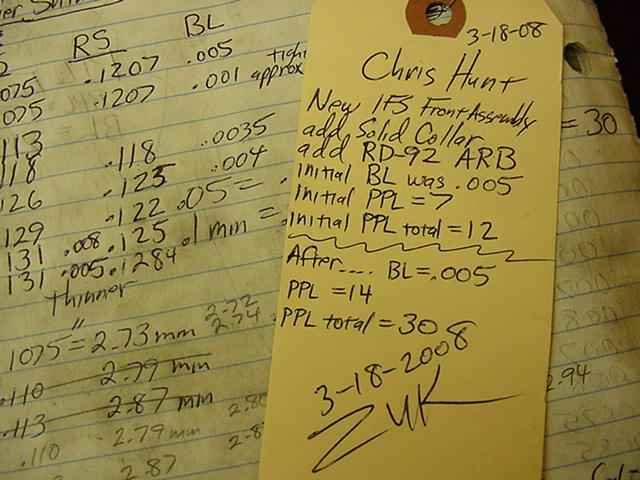

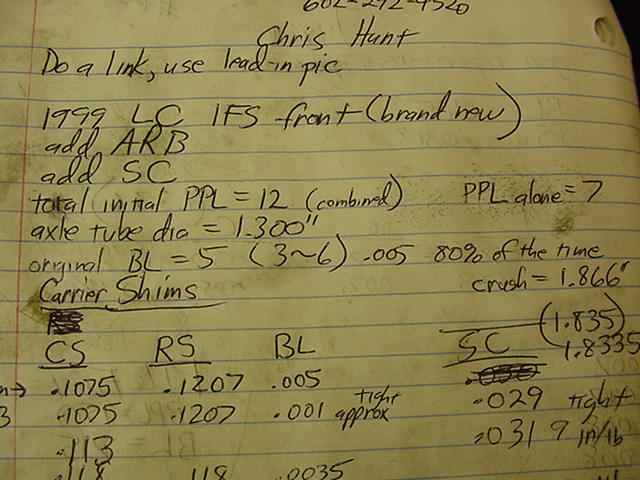

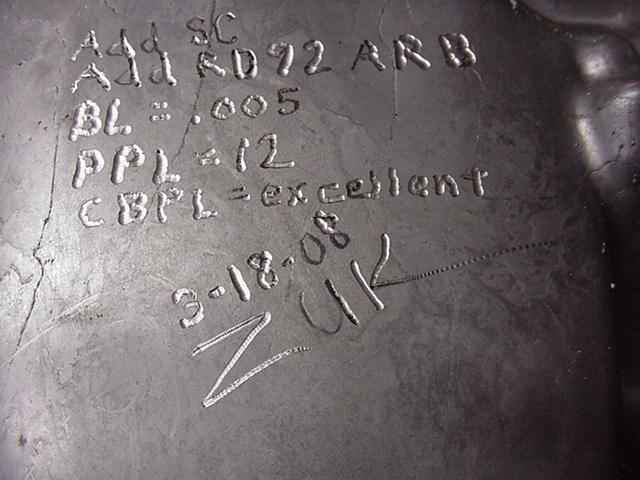

Chris chose to replace the whole front assembly. Also, to be installed, is a new ARB RD-92 and a solid collar.

|

|

|

Just for fun, I measured the total PPL to turn the pinion and the ring gear both...I measured a very modest 12 inch/pounds.

|

|

|

The aluminum cover is removed.

|

|

|

I could use my pinky to wiggle the ring gear which suggests low CBPL.

|

|

|

The 4 long bolts have already been removed and I'm using the screwdriver to drive out the longside axle stub.

|

|

|

Then the axle tube can easily be removed. By the way, the ring and pinion are reverse cut 8" V6 gears....it uses the typical

V6 4 pinion case.....also, the big inner pinion bearing is the usual V6 bearing.

|

|

|

A nice stout 1.300" diameter axle.

|

|

|

I made up this "2nd generation" universal fixture for holding the 3rds in place rigidly. This is my best design yet. :)

|

|

|

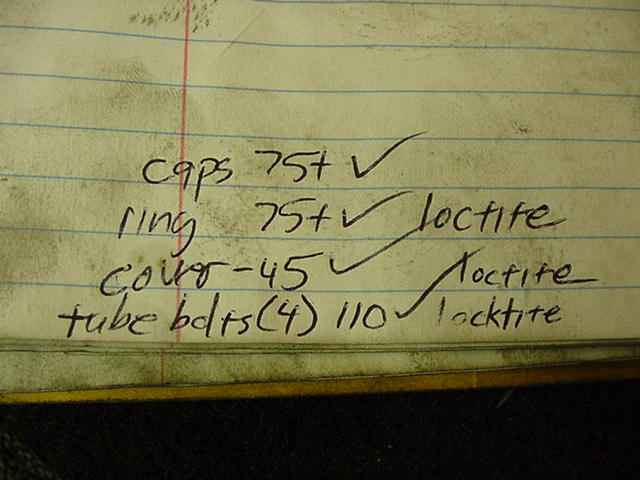

I carefully checked backlash in numerous places and found that it was very consistently at .005".

|

|

|

Bearing caps were marked and the case was pryed out. Not that much pry effort was needed.....but will be when I

get done with it.

|

|

|

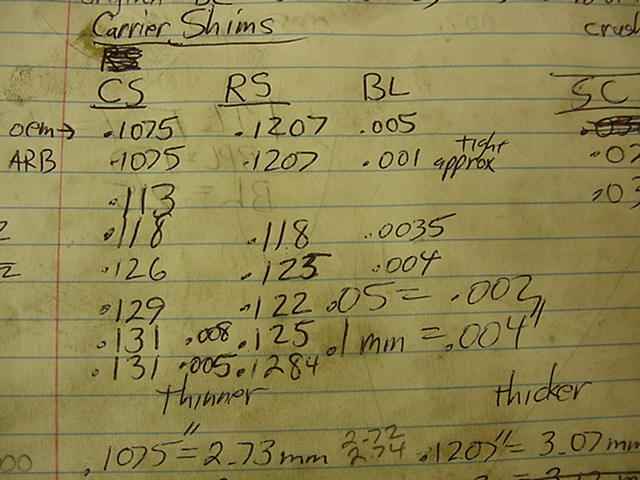

The carrier bearing washer plates (thick shims) are cataloged. These OEM plates are not stocked at any of the

Toyota dealerships (according to my local dealer) and takes about 3 or 4 weeks to get from Japan. Fortunately,

I have other washer plates and shims that will get the job done.

|

|

|

Now's a good time to install the solid collar. First, remove the yoke.

|

|

|

Use the 12 ton press to softly push out the pinion.

|

|

|

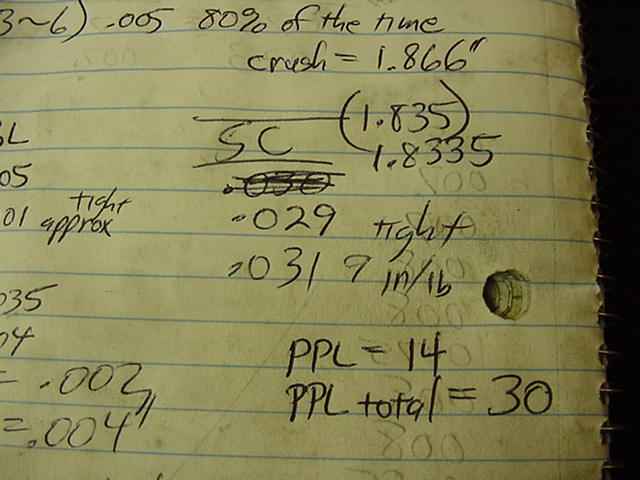

The solid collar is slipped in place and a .031" shim pack is added in...

|

|

|

The yoke is carefully pressed in place so as to not cause any damage to the oem seal.

|

|

|

The ring side carrier bearing is removed...

|

|

|

...and pressed onto the ARB case.

|

|

|

The usual precautions are observed when the ring gear is swapped over to the ARB. File, loctite, and torque to 75.

|

|

|

To get the backlash right and the CBPL high involves numerous tries with select shims. Done right, this can take an hour sometimes.

|

|

|

Per the supplied instructions, the hole location is marked...

|

|

|

...and drilled with a 7/16" bit.

|

|

|

A 1/4 NPT tap makes the threads and the liquid teflon seals the brass fitting nicely.

|

|

|

Last chance to add a couple thousandths of CBPL.

|

|

|

The shim on the right side is a V6 washer plate used on the 1986~1995 IFS truck fronts.

It's a close enough fit for this application.

|

|

|

The adapter bearing used by ARB has a cage that sticks out just a small amount...

|

|

|

...enough to cause a contact mark when the oem washer plate is used.

|

|

|

Fortunately, ARB supplies a small stack of shims that clears.

|

|

|

Using just my palm to push the washer plate on the right in place and then the hammer can tap the plate home. This should

take some good effort guaranteeing excellent CBPL.

|

|

|

Copper routing per the manual...

|

|

|

Drive pattern is checked. Nice.

|

|

|

Coast. Nice.

|

|

|

Leak test.

|

|

|

The total PPL (turning both the pinion and ring) is now 30...it was only about 12 from the factory.

|

|

|

The axle stub is installed...

|

|

|

The pinion nut was loctited and staked...

|

|

|

The cover is rtv'd and torqued in place.

|

|

|

...................................................

|

|

|

.............................................................

|

|

|

...................................................

|

|

|

.................................................

|

|

|

....................................................

|

|

|

Done.

|

|