| Chris's 2014 Tundra with the BIG 10.5" ring gear gets Nitro 488 gears |

|---|

| (66 BIG pics loading) |

|---|

| JULY 11 2017 |

|---|

|

Chris from Alabama has quite the Tundra....a 2014 Platinum Crewcab 4x4 5.7 liter.

The plan is to take out the factory 430 gears and install Nitro 488 gears both in the 10.5" rear 3rd and the 9" front clam. |

|---|

|

|

Here are some of the performance mods Chris has done to it....

-7" bds suspension lift with Fox coilovers

-37/13.50r20 Cooper Discover stt pros

-20x10 Fuel Mavericks with machined faces

-Ekstrom design tie rod ends

-Zone carrier bearing drop kit

-4.88 nitro gears

Video of Chris's Tundra and the professional shop that installed the lift

NothingButLifts.com |

|---|

|

|

| The heavy 108 pound diff is on the bench and the Nitro product in the background. |

|---|

|

|

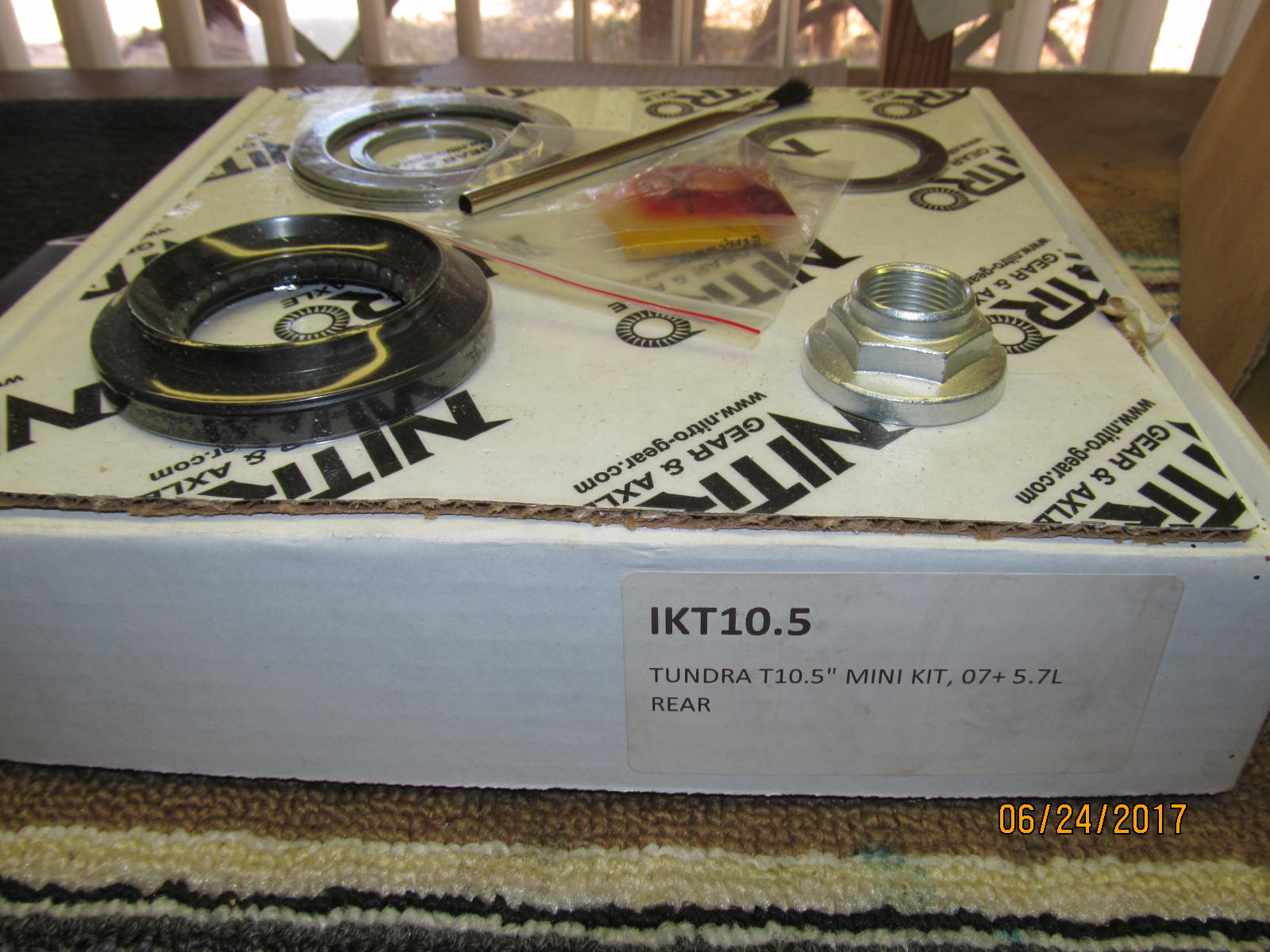

| Nitro mini-kit |

|---|

|

|

| 23 pounds of Nitro 488 ring and pinion |

|---|

|

|

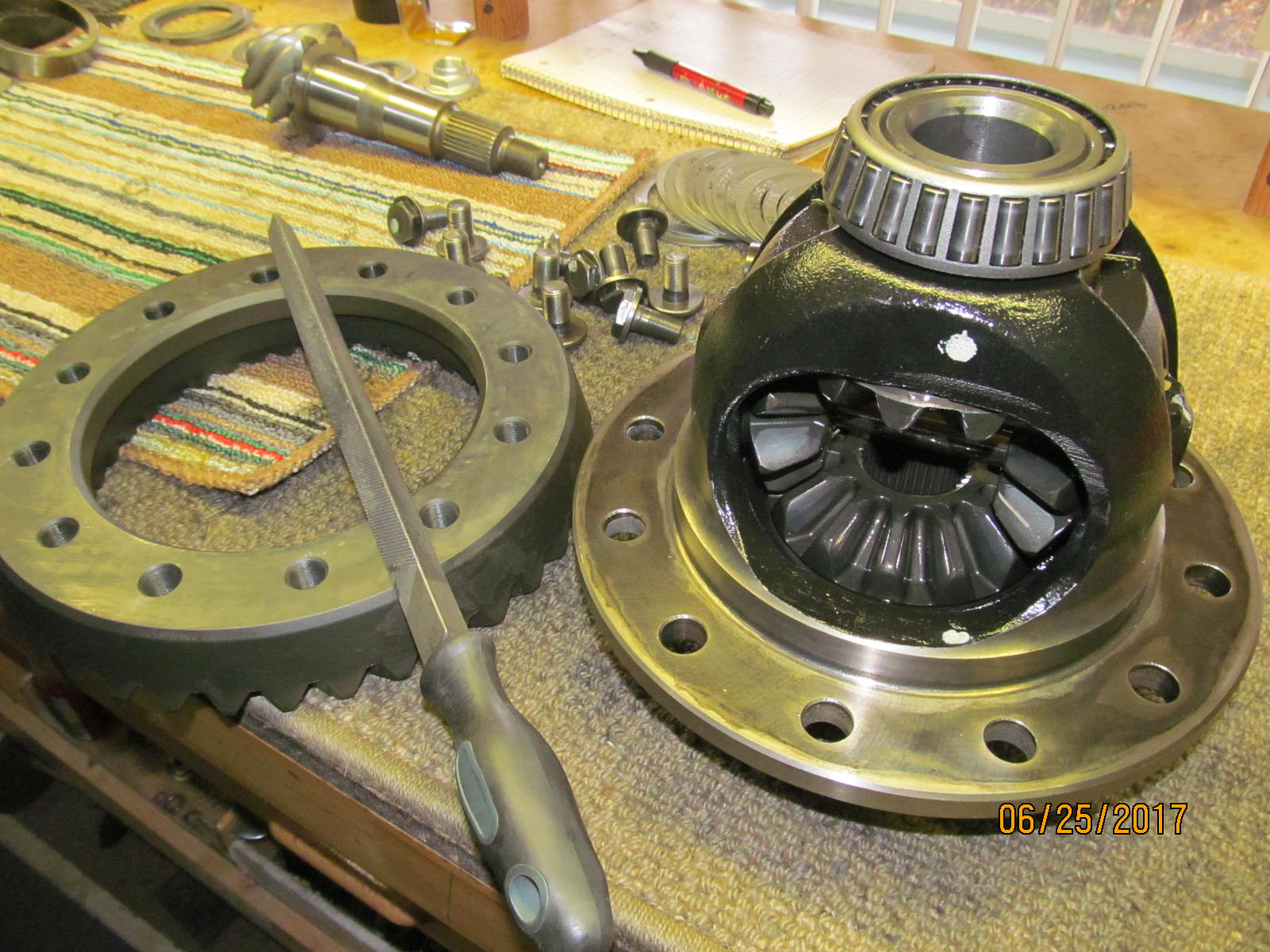

| Remove the caps... |

|---|

|

|

| Remove and document the carrier bearing washer plates. |

|---|

|

|

| Digital cameras can be mis-leading sometimes but these massive carrier bearing on this 2014 truck look very nice and perfectly re-usable. |

|---|

|

|

| another angle.... |

|---|

|

|

| The 12 ring gear flange style bolts were on very tight. The factory used a high strength thread lock also. |

|---|

|

|

| ...................................... |

|---|

|

|

| My electric impact did not have the torque to power them off so a long cheater bar had to be used. |

|---|

|

|

| Bolts are cleaned up on a high speed wire wheel. |

|---|

|

|

| Surfaces are checked with a file and they were all smooth and burr free. |

|---|

|

|

| Blue Loctite and 145 ft/lb per the fsm factory manual. |

|---|

|

|

| The carrier end is now complete. |

|---|

|

|

| Now to remove the 4.30 pinion. As expected, the oem nut was on very tight. Leverage won out. |

|---|

|

|

| The factory 32 spline flange was like new. |

|---|

|

|

| Pressing the pinion out. |

|---|

|

|

| The factory seal is a 90311-378KM part number. |

|---|

|

|

| Made in the USA. |

|---|

|

|

| The outer pinion bearing is actually a pretty stout size and in very nice condition. |

|---|

|

|

| The thick factory sleeve uses 2 "shims"...I found one stuck to the sleeve...... |

|---|

|

|

| ...and one stuck to the underside of the outer pinion bearing. Sort of the same thing that they do on the crush sleeve of the 8.4" diff. |

|---|

|

|

| ............................ |

|---|

|

|

| Pressing the inner pinion bearing off. |

|---|

|

|

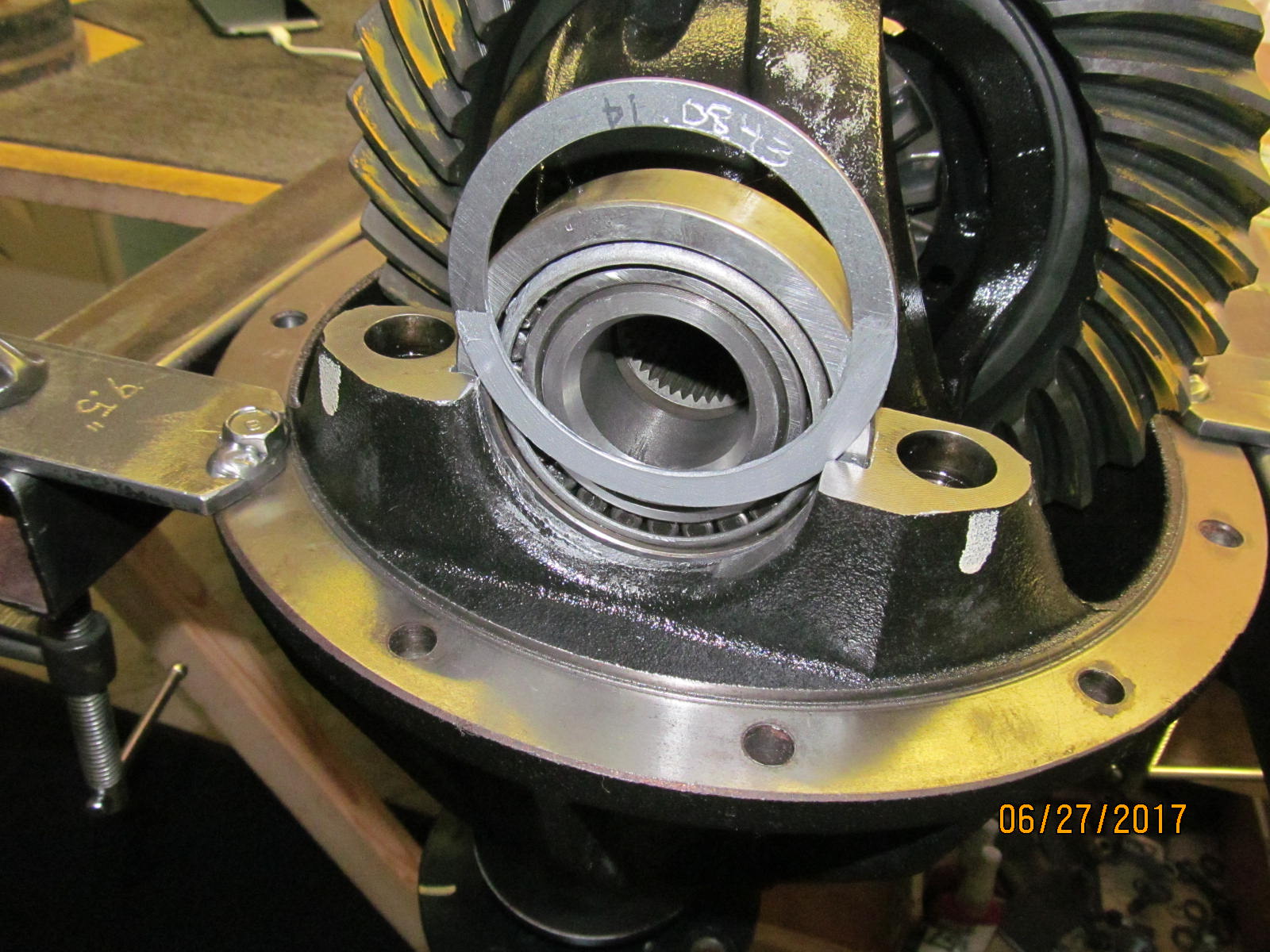

| The new 488 pinion will see the .052" shim and the used bearing. |

|---|

|

|

| Pressing the bearing on the 488 pinion. |

|---|

|

|

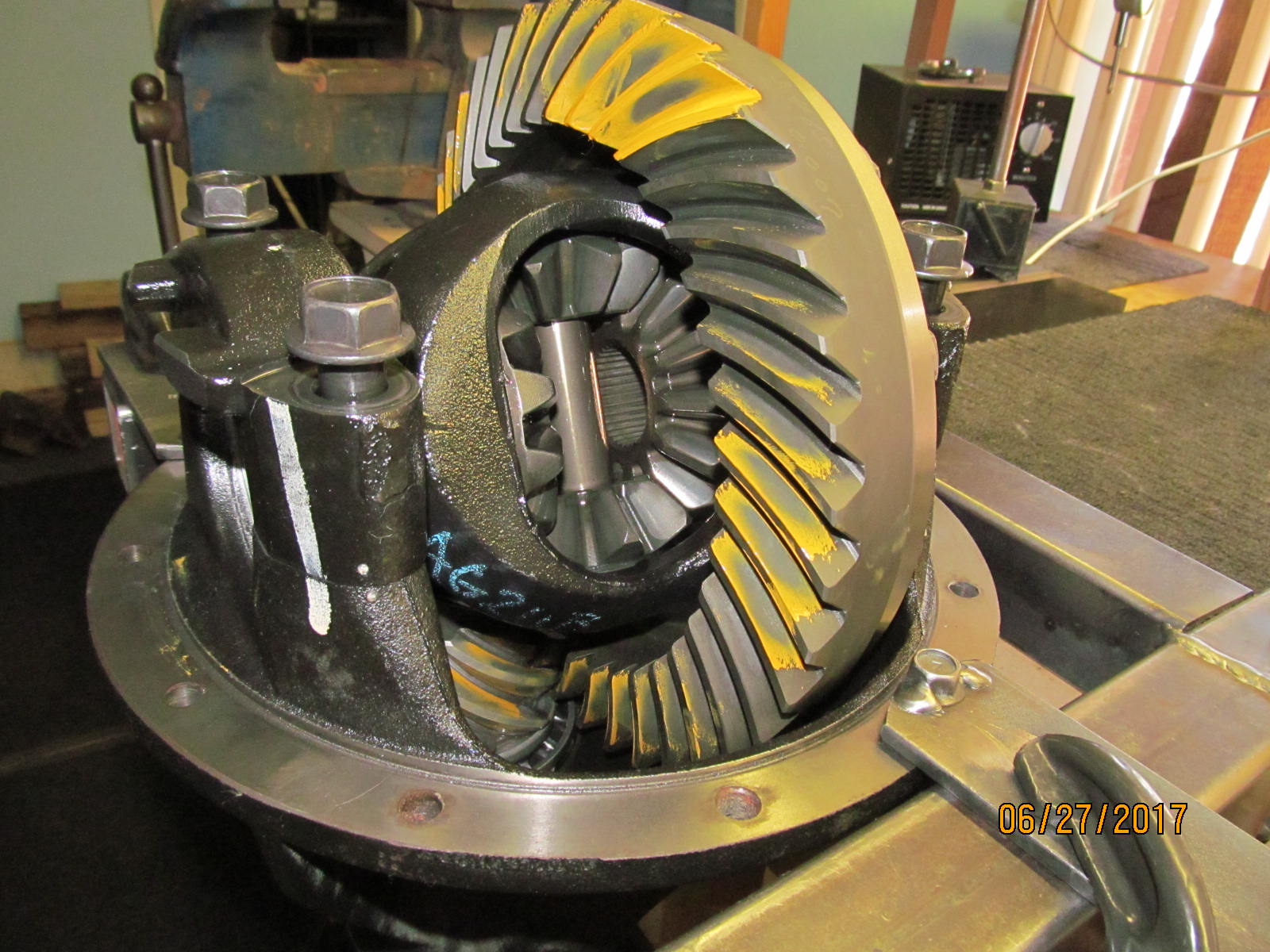

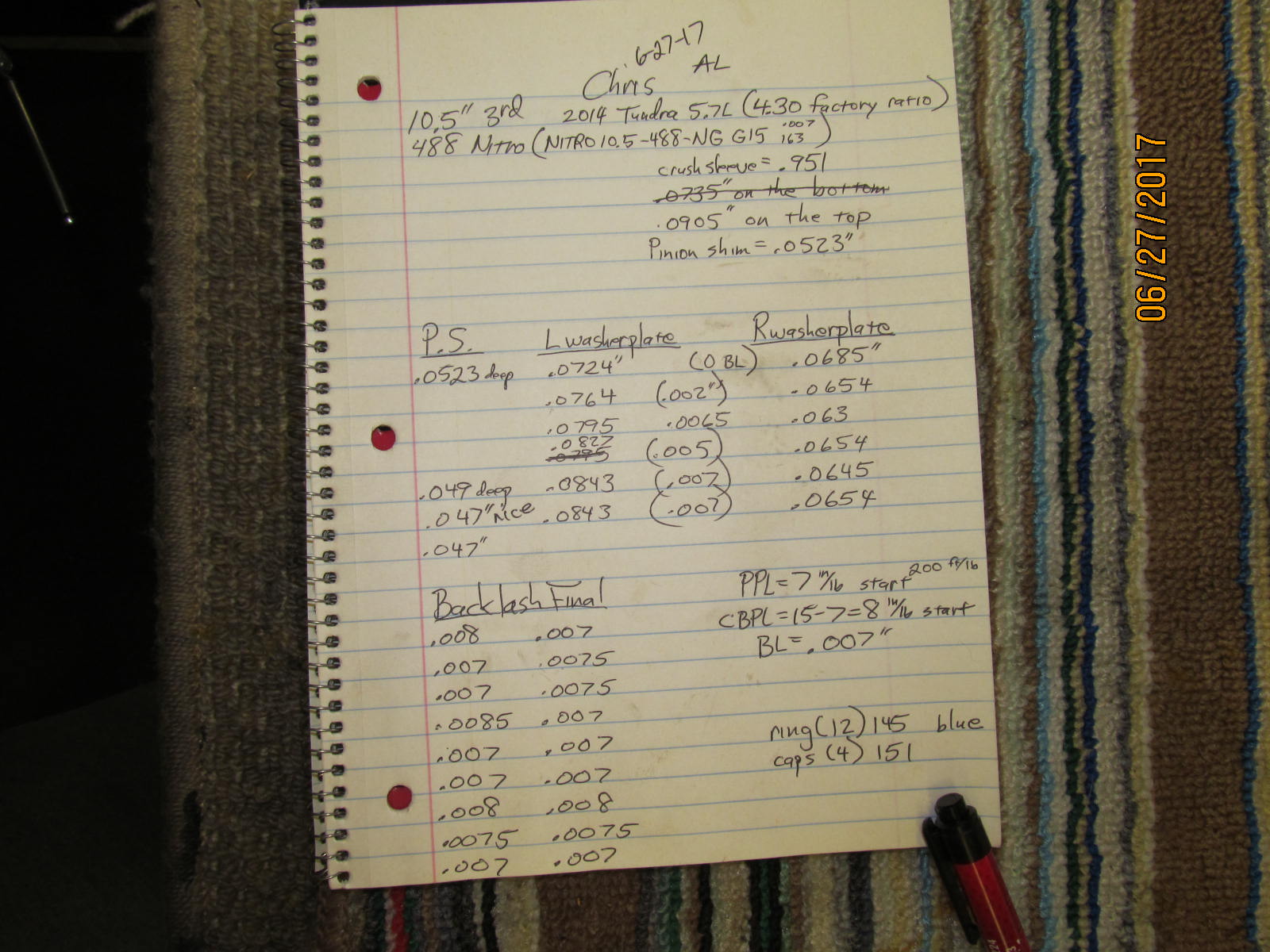

| Now to assemble it for a paint test. Pinion nut was run tight with the impact wrench and pinion turned nice and free. |

|---|

|

|

I have a good selection of the genuine factory carrier bearing washer plates on hand.

The mini-kit had a shim selection but sometimes they just don't do the job like the factory washer plates.

The factory washer plates were way off with this Nitro 488 as the backlash was almost exactly Zero.

One plate made about 10 thou thicker and the other was about 3 thou thinner for this paint test. |

|---|

|

|

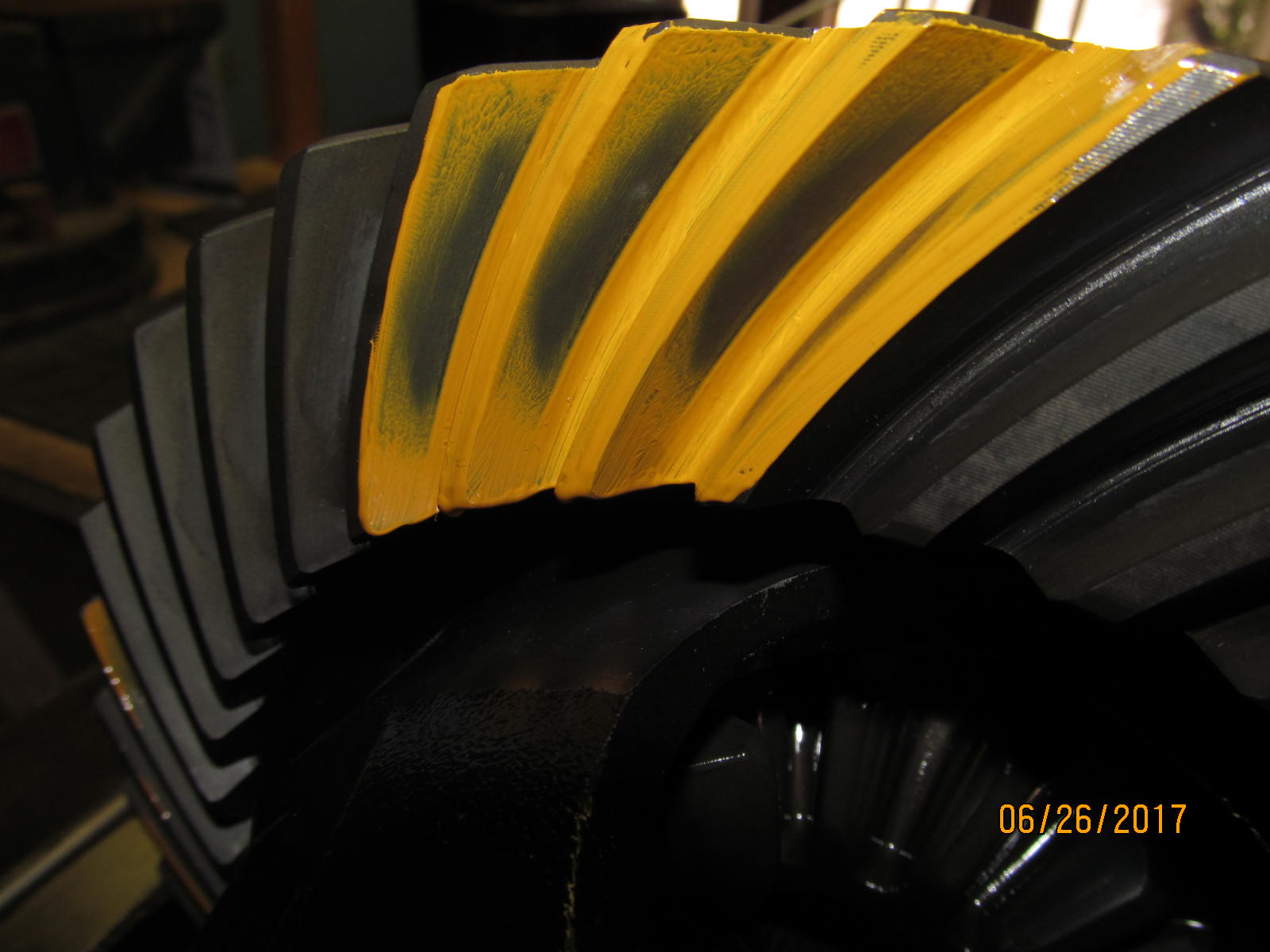

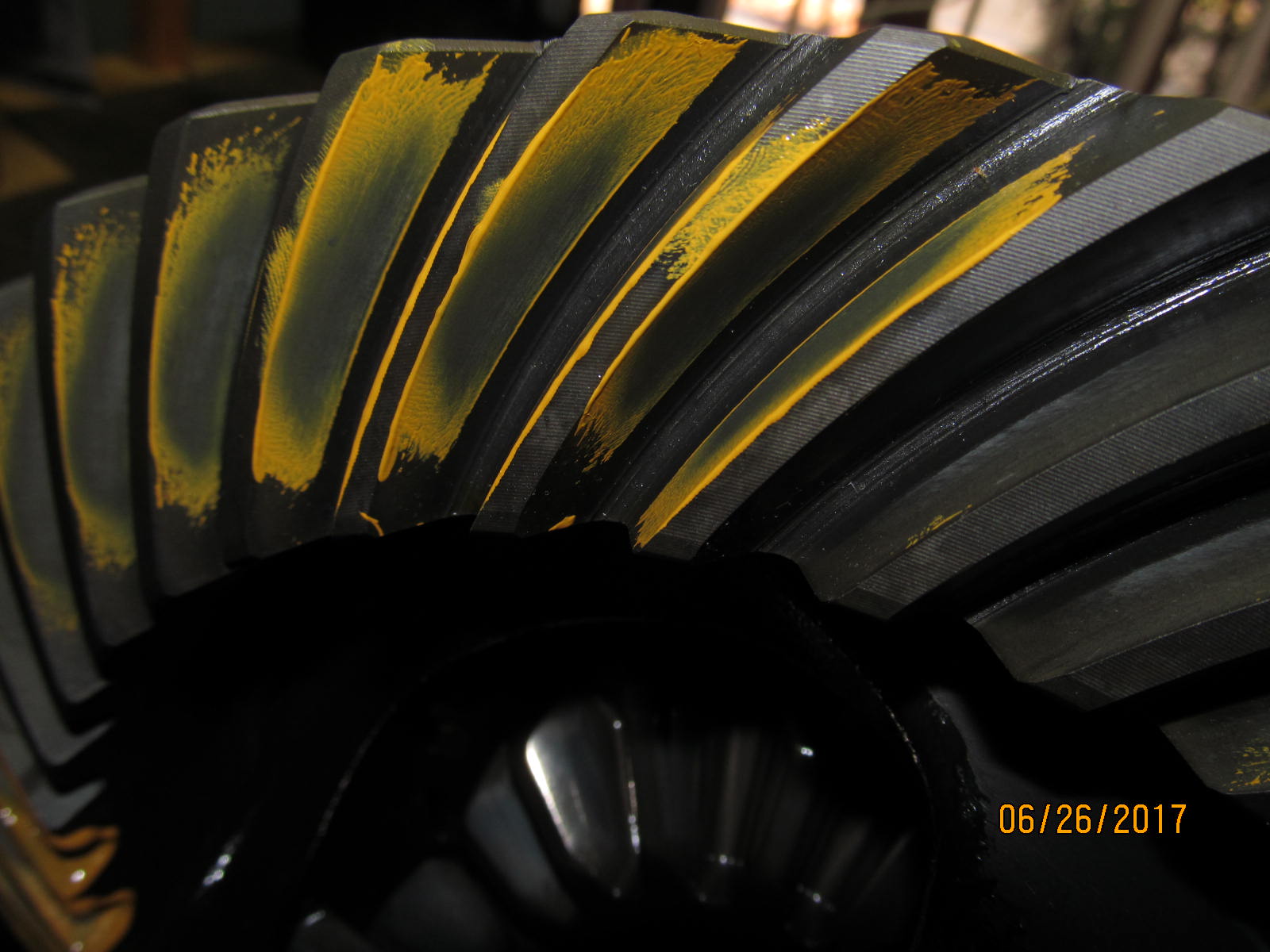

| Drive....a little too deep. |

|---|

|

|

| Coast .....reflects that same thought. |

|---|

|

|

| Teardown and out comes the pinion. |

|---|

|

|

| A modest change to 049. |

|---|

|

|

| And a modest tweaking to get the backlash even closer to the .007" spec engraved on the ring gear. Add .002 to this side and take .001 off the other. |

|---|

|

|

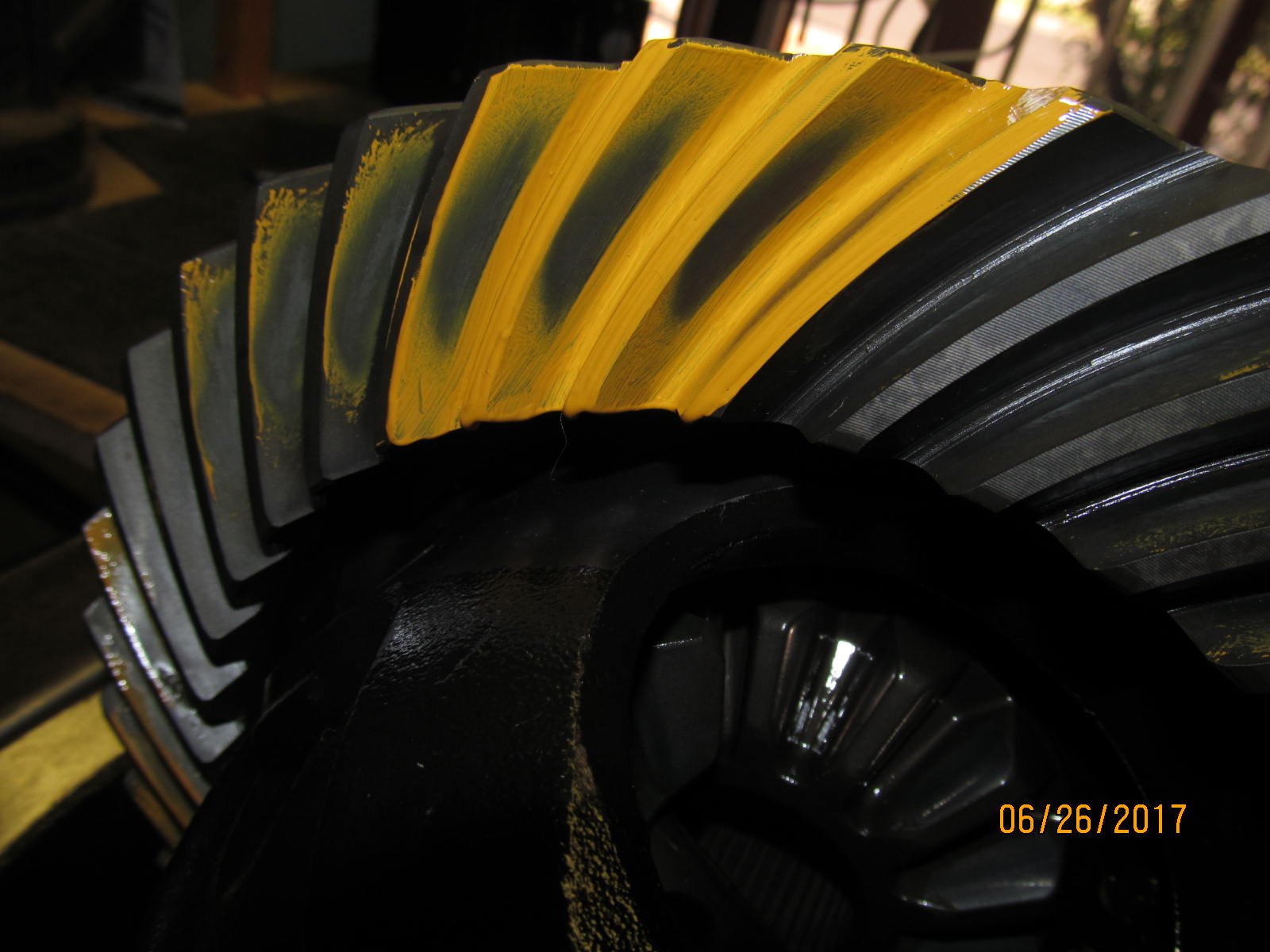

| Drive. Closer but just a little too deep for my taste. |

|---|

|

|

| Coast. Tad too deep. |

|---|

|

|

| A final teardown/adjustment. This time .047". |

|---|

|

|

| Another tweaking.... .001" thicker.....see the notes at the end. Carrier bearing preload here is good. |

|---|

|

|

| Permatex Anti-seize was thinnly applied to help it smash into place without damage. |

|---|

|

|

| Drive...now this is what I like to see. Either go "exact depth" or slight deep but never shallow. This is slight deep. |

|---|

|

|

| Coast is beautiful. |

|---|

|

|

| Drive..... on the reverse painted teeth. |

|---|

|

|

| Coast....reverse painted. |

|---|

|

|

| Last chance to splash some clean gear oil on the outer bearing....and then the slinger goes in place. |

|---|

|

|

| The seal supplied in the Nitro mini-kit was the same exact oem seal as I took out. |

|---|

|

|

| Tap it in with 360 degree support. |

|---|

|

|

| Flush with the steel lip....and make sure the garter spring is not laying on the slinger. |

|---|

|

|

| A light coating of gear oil on all parts that will contact rubber. |

|---|

|

|

| The bottom of the new flange nut did see some anti-seize. |

|---|

|

|

| 200 ft/lb of torque..... |

|---|

|

|

| ....to yield about 7 in/lb of pinion bearing preload which is good for used pinion bearings. |

|---|

|

|

| DING! and this end is now done. |

|---|

|

|

| They went in tight like the should....tighter than what the factory set them to I noted. |

|---|

|

|

| More anti-seize... |

|---|

|

|

| Bearing caps go on... |

|---|

|

|

| 151 ft/lb per the specs |

|---|

|

|

| Some strong raps to absolutely equalize the carrier bearing tensions..... |

|---|

|

|

| Actually checked in at 15 or 16..... |

|---|

|

|

| Backlash is recorded on every other tooth for about 20 readings. |

|---|

|

|

| Notes recorded during the install |

|---|

|

|

| Boxing up the 110+ pounds of diff. That's a square piece of very high density foam. |

|---|

|

|

| Almost ready to back to Chris. |

|---|

|

|

|