| Juan's 2004 100 series Landcruiser gets a front Harrop and Nitro 488R gears |

|---|

| (66 BIG pics loading) |

|---|

| January 4 2018 |

|---|

|

| Juan shipped me both of his diffs from Alabama. The Harrop elocker can be seen with the Nitro product. |

|---|

|

|

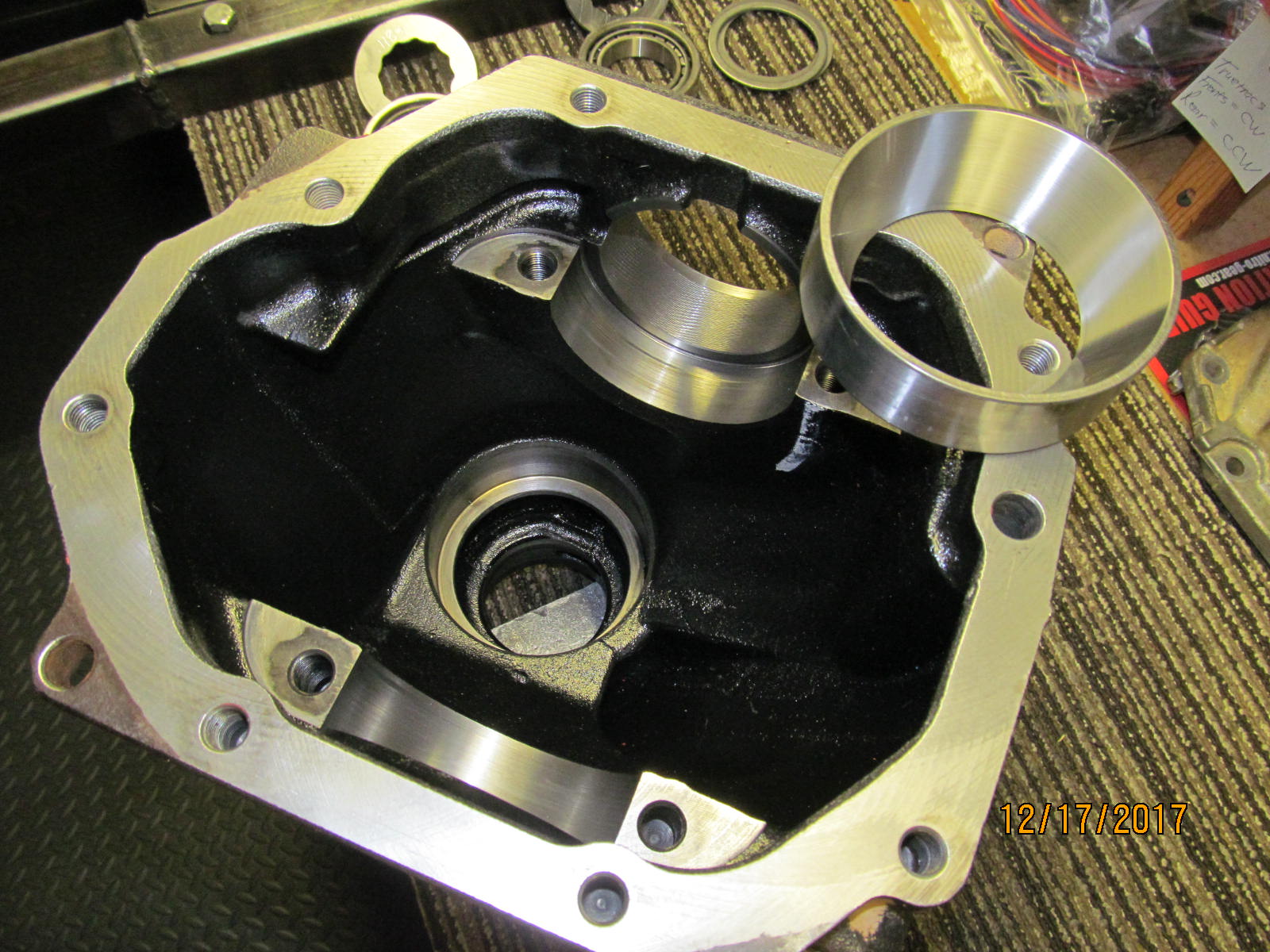

| A solid collar will be added and new flange, also. |

|---|

|

|

| Both caps are marked in such a way that they cannot get flipped around or interchanged. |

|---|

|

|

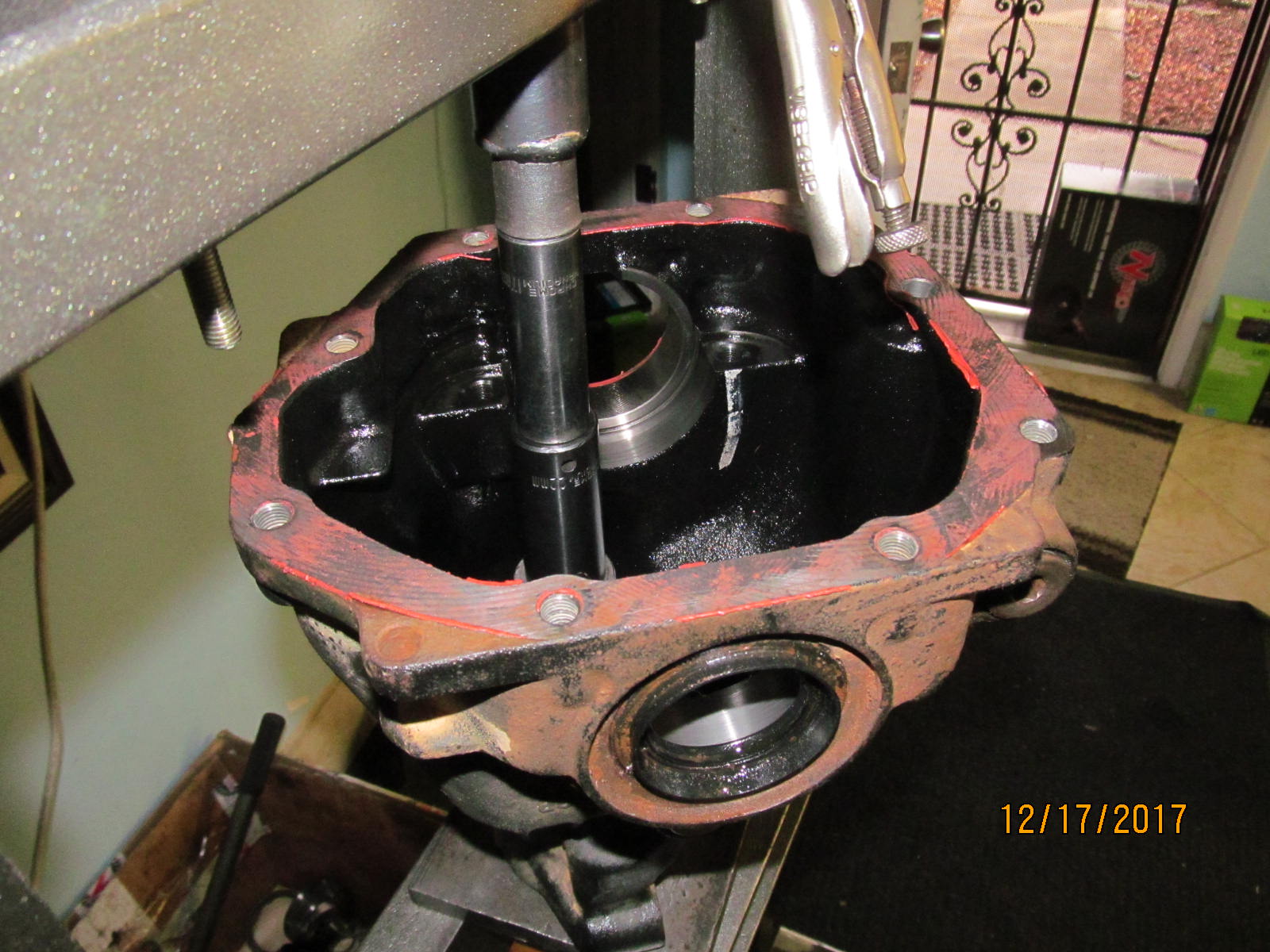

| Start with pressing the old pinion out. |

|---|

|

|

| Now press the outer race out. The large inner race also gets pressed out. |

|---|

|

|

| Take this nasty looking CV axle seal out. |

|---|

|

|

| Both related bodies have been cleaned properly. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| ................................. |

|---|

|

|

| All loose grit has been removed...mostly with a toothbrush size wire brush. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| ............................... |

|---|

|

|

| ................................... |

|---|

|

|

| With everything stripped down and clean, now the new Koyo inner race can be tapped in place. |

|---|

|

|

| Verified 100% seated down. |

|---|

|

|

| Same with the new outer race....100 seated down. |

|---|

|

|

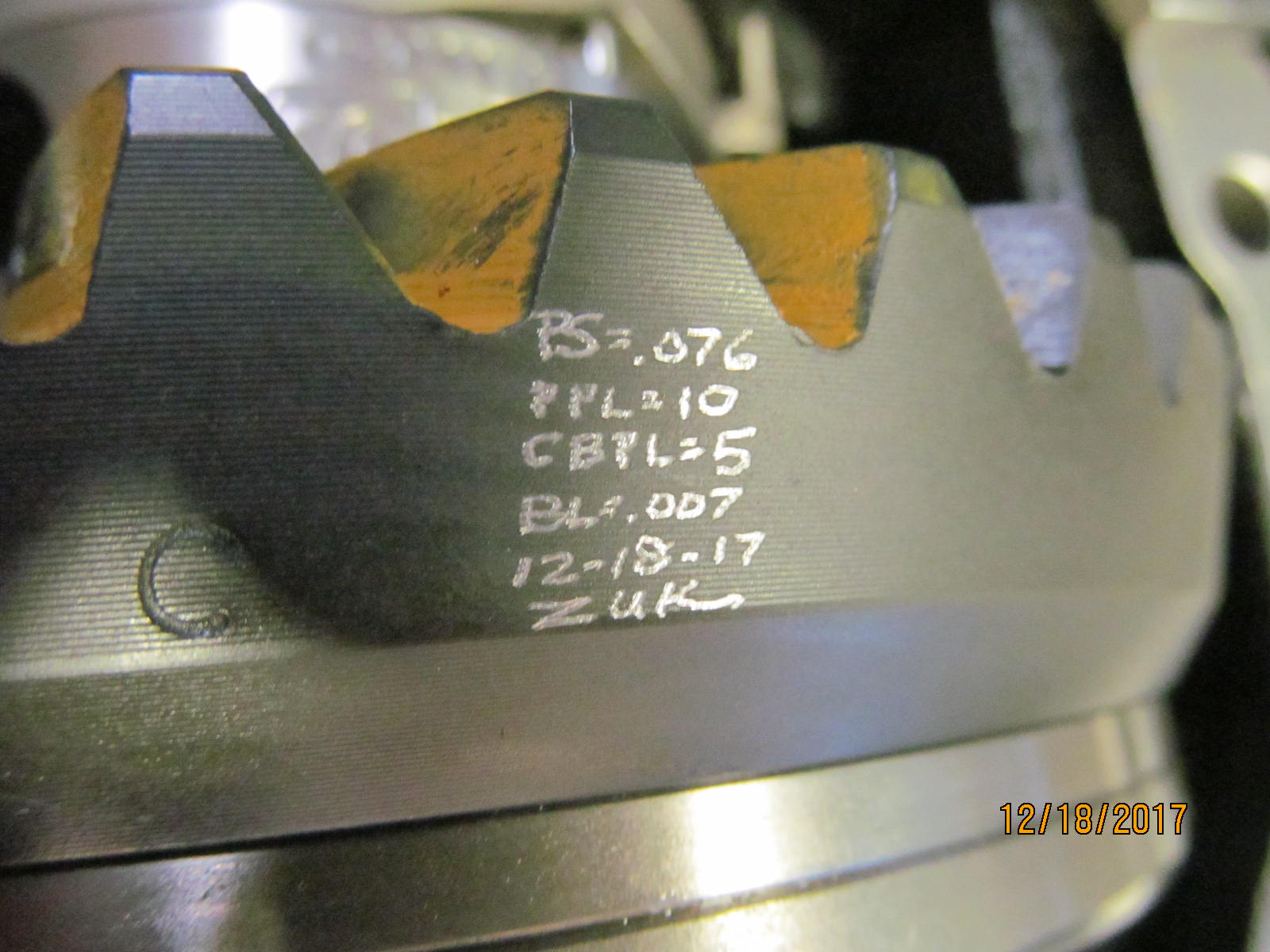

| .076" will be the 1st try at proper pinion shim depth. |

|---|

|

|

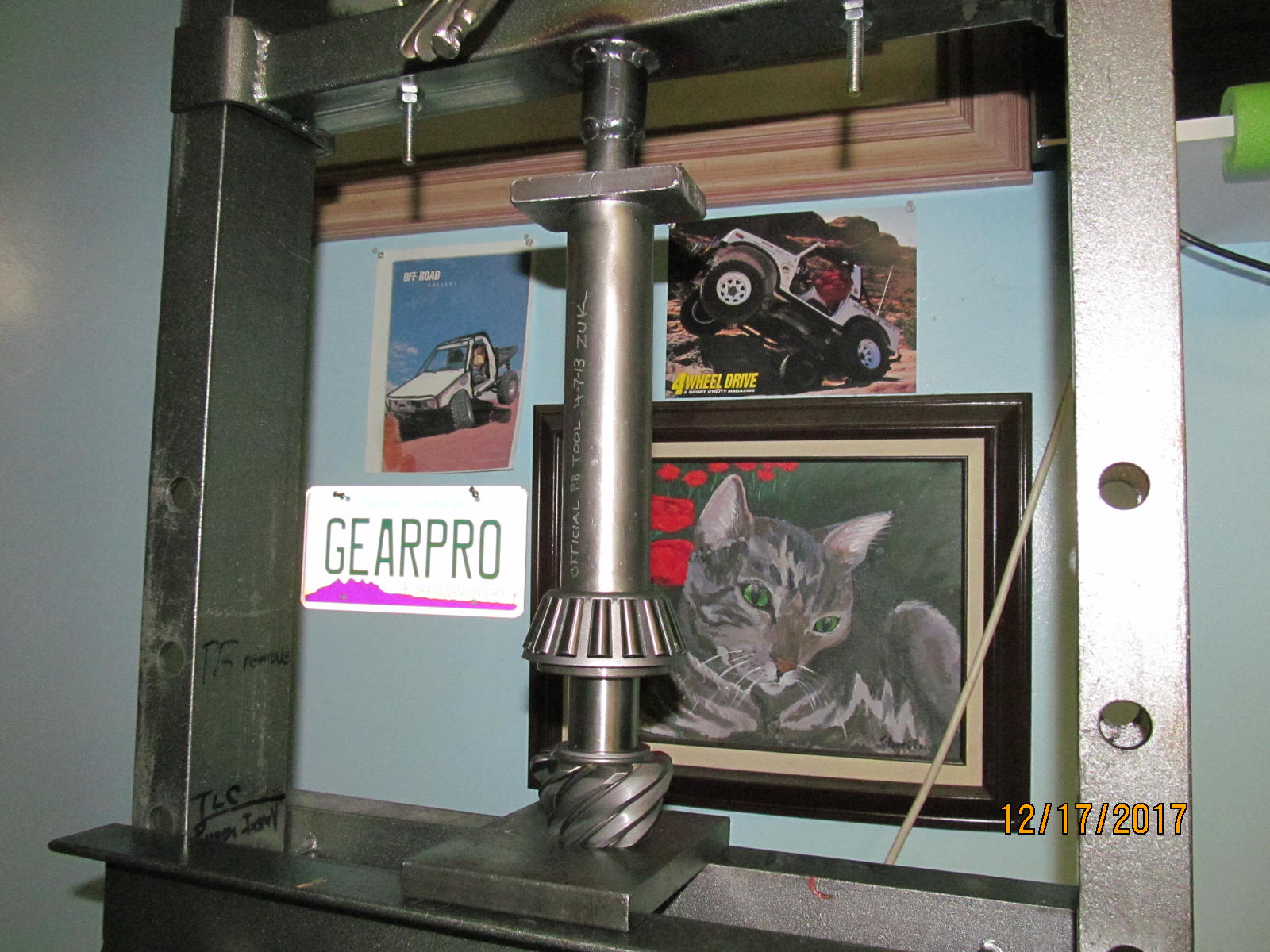

| The new pinion bearing is pressed on with the 076 shim. |

|---|

|

|

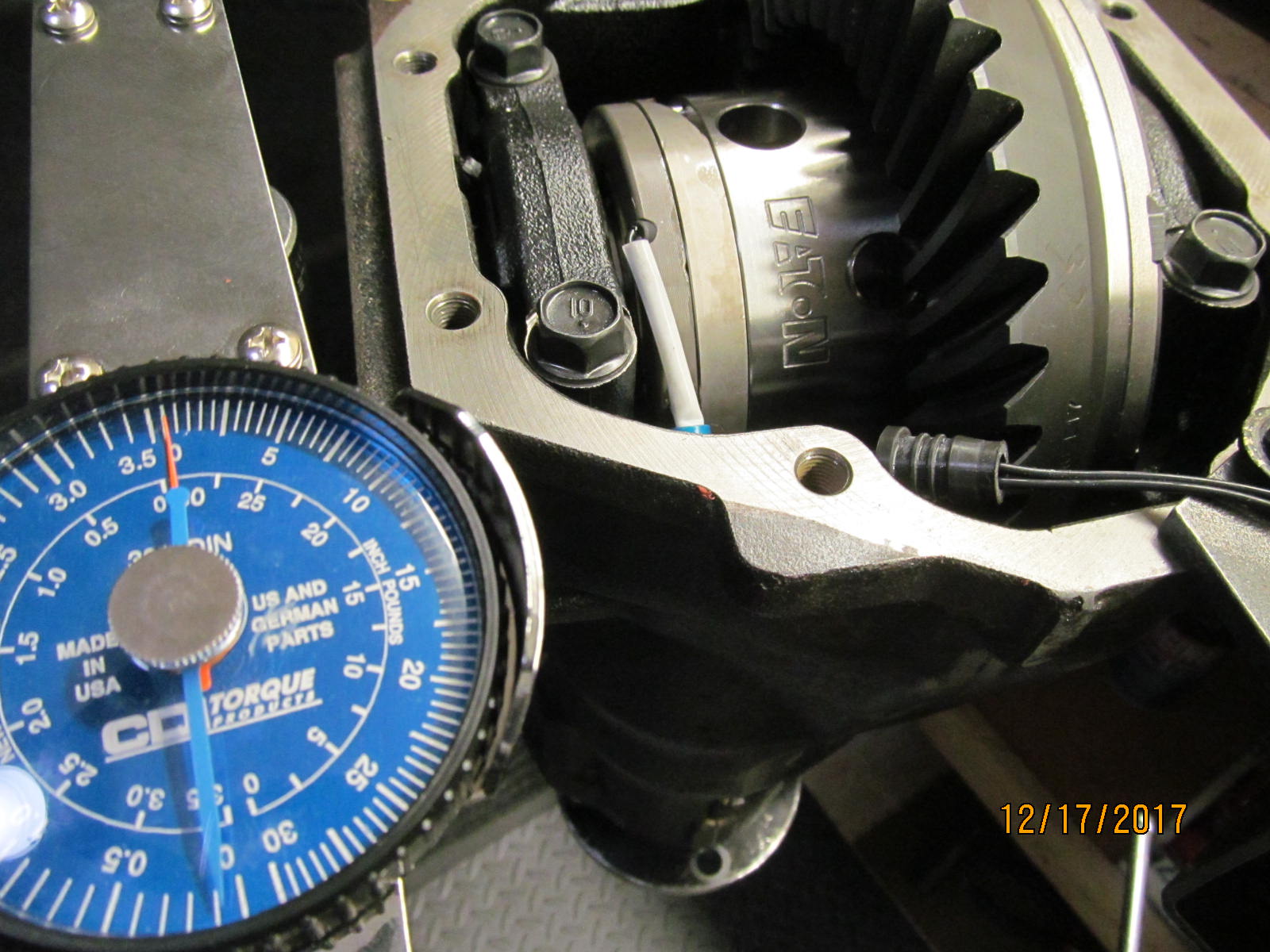

This is just for a paint test but I was curious ....and wanted to show off my fairly new torque measuring tool.

A modest 8 in/lb of torque but just fine for this paint test. |

|---|

|

|

Surfaces are checked with a file and no unusual burrs were found.

Carrier bearings and the ring gear do need to be mounted up. |

|---|

|

|

| As indicated by my dainty grip near the hammer head, this ring gear went on easy. More of a slip fit. |

|---|

|

|

| 71 ft/lb per the fsm and a little blue Loctite. |

|---|

|

|

| With the right widget, the new carrier bearings can be tapped into place. |

|---|

|

|

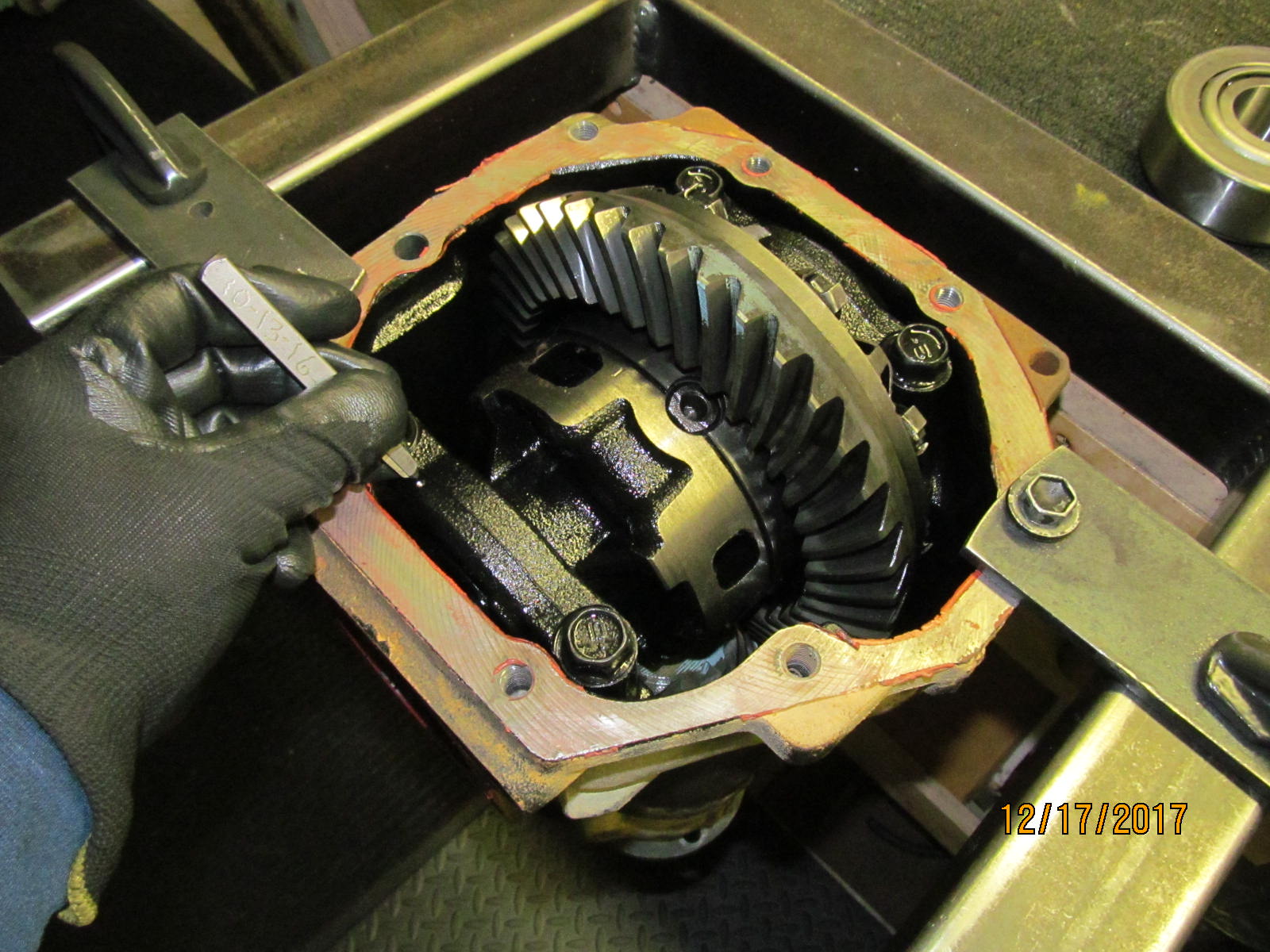

| Then the Harrop case is loaded in place and caps tightened up. |

|---|

|

|

Re-using the existing washer plates resulted in 22 in/lb of total preload.....a little high but ok for a paint test.

The backlash was about .008" so no issues there. |

|---|

|

|

Drive side....the pattern depth seems surprisingly good and appears to be a keeper.

Slight favoring to the heel but very little can be done about that. |

|---|

|

|

| Coast....appears to be at the ideal depth and well centered in the tooth. |

|---|

|

|

| Comet tail is not harshly tucked into the root. |

|---|

|

|

| Easier to see the comet tail trying to be a bit in the center. |

|---|

|

|

Really easy to see it in this shot....the comet tail is indeed in the center

and that means the pinion shim is in a "slight deep" state and leave it alone. |

|---|

|

|

| With depth established, now to install the solid collar. |

|---|

|

|

| On the second try, the perfect shimming was found. |

|---|

|

|

| This is a good quality seal made by THO in Japan so let's use it. |

|---|

|

|

| '''''''''''''''' |

|---|

|

|

| '''''''''''''''''''''' |

|---|

|

|

| "THO" located in Japan. |

|---|

|

|

| New flange style nut. |

|---|

|

|

| Pinion preload was verified with the torque wrench. A nice, smooth 10 inch/pounds of pinion preload. |

|---|

|

|

| DING! and this end is done. |

|---|

|

|

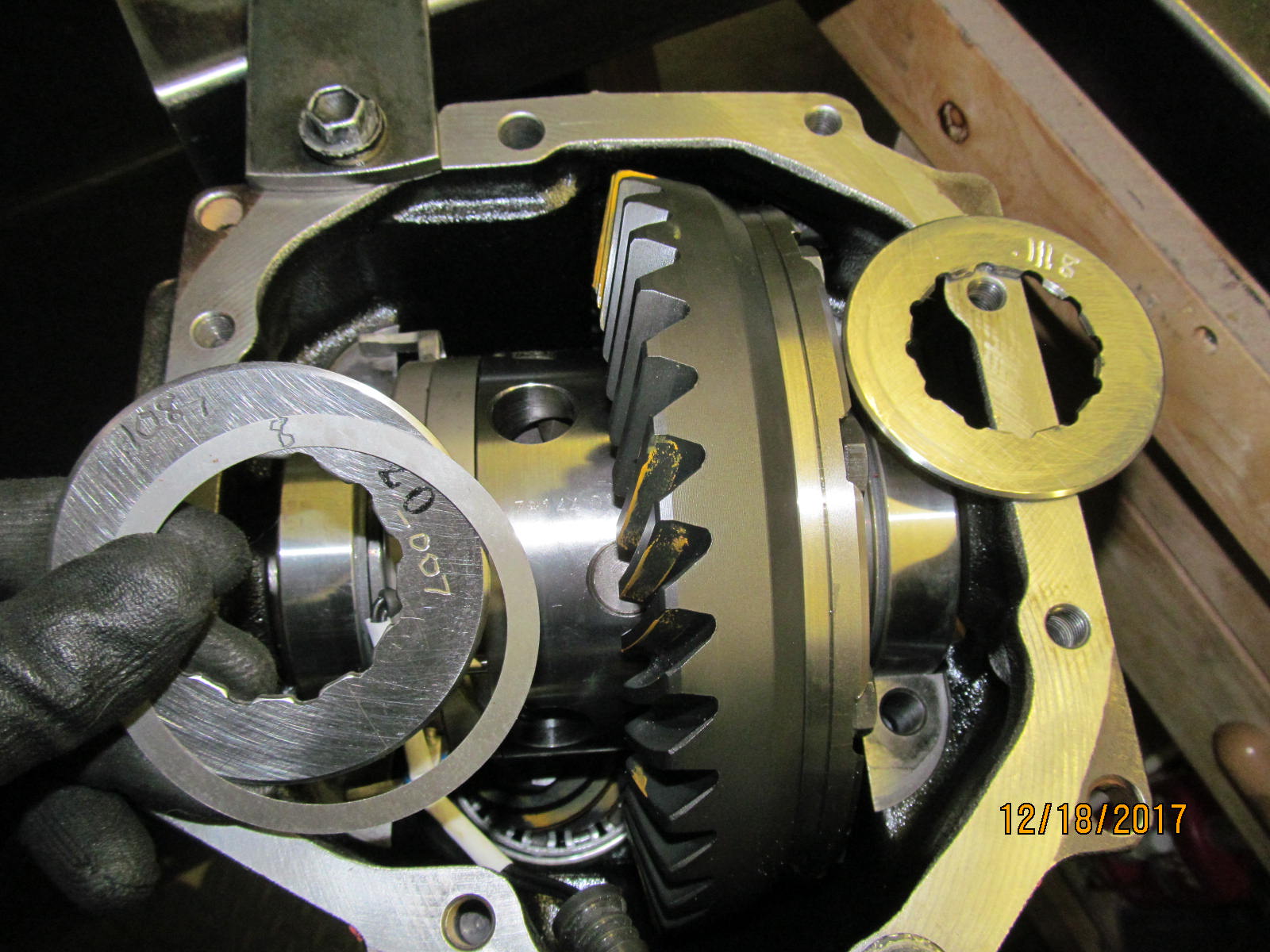

| For setting the backlash and carrier bearing preloads, a good selection of washer plates is a plus. |

|---|

|

|

| A fine tuning of the backlash while reducing the preload somewhat was the goal and .117" on the left side did the trick. |

|---|

|

|

| Backlash was recorded on approximately every other tooth. |

|---|

|

|

| The 4 bearing cap bolts were verified to be at 63 ft/lb per the fsm. |

|---|

|

|

Good luck finding installation notes on the A10976 Harrop because there are none.

Common sense goes a long way :) Some grinding on the caps. |

|---|

|

|

| Drill the 29/64" hole just about where it is shown here. Coat the rubber grommet with black rtv. |

|---|

|

|

| And it slides thru as easy as butter maybe. |

|---|

|

|

| Here's what the placement looks like on the outside. |

|---|

|

|

This is a picture that Juan sent me of the nearly finished installation under his Cruiser and there is

plenty of room for the connection on top. No interference issues. |

|---|

|

|

| Back to the testing of the Harrop....the measured resistance was 3.9 ohms. |

|---|

|

|

Now the 12 volt battery test. No polarity on these 2 black wires

so it does not make any difference which way it is hooked up....

just as long as it is hooked up. |

|---|

|

|

Apply red to (-) and black to (+)....or is it the other way around

It makes no difference. :) |

|---|

|

|

With the electromagnet engaged, the ramp ring is held firmly to it.

So turning the pinion flange which turns the ring gear results in

the 3 engagement pins being pushed in the case. The locker is fully engaged now. |

|---|

|

|

| Notes are scribed on the ring gear. |

|---|

|

|

| Seals are next. |

|---|

|

|

| tap tap. |

|---|

|

|

| This CV side seal is fully in now. |

|---|

|

|

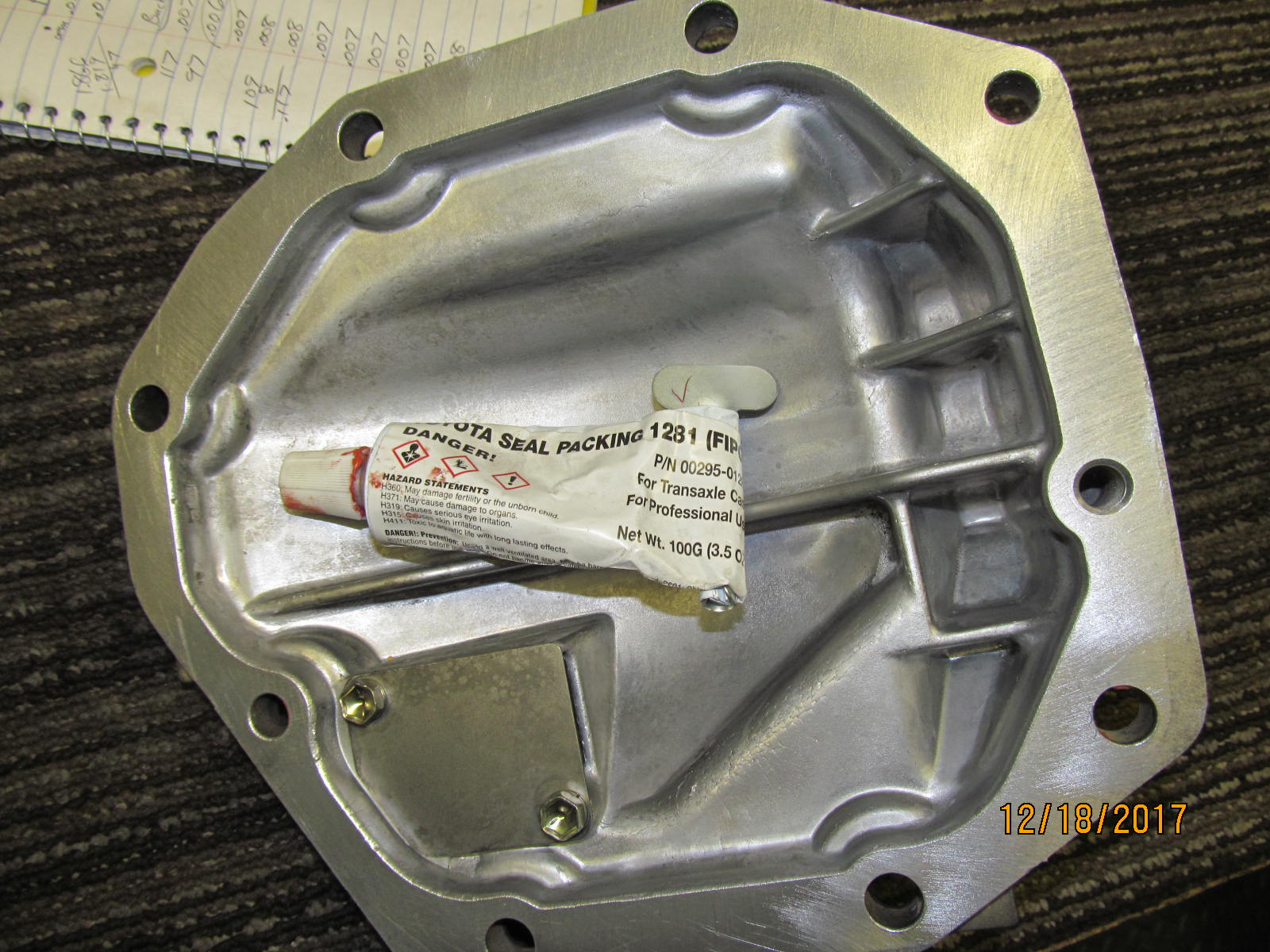

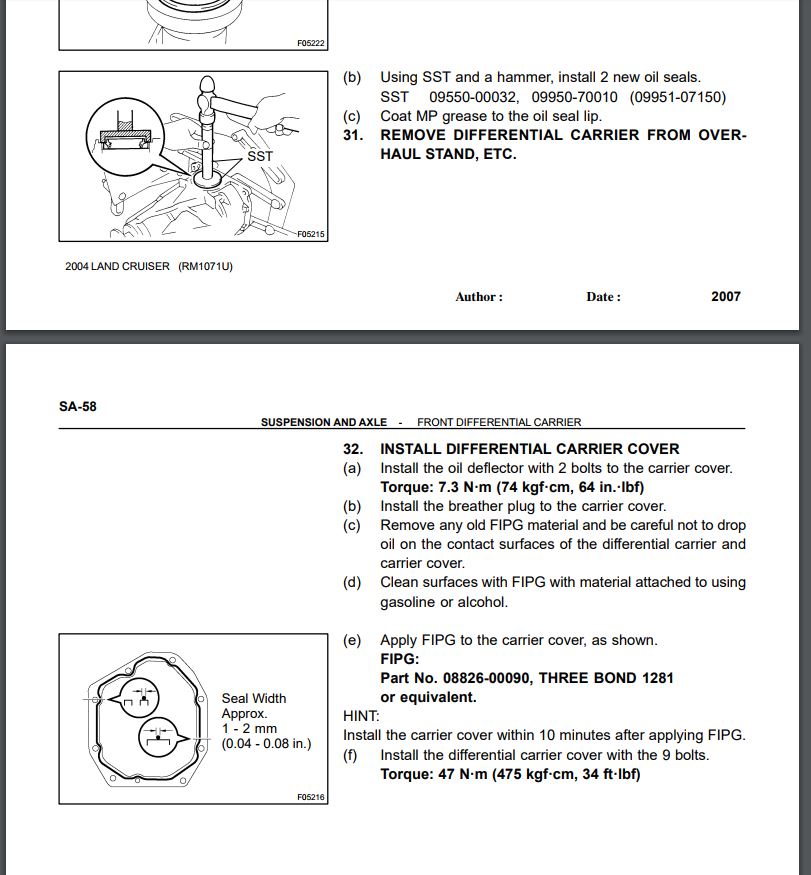

| Aluminum cover is clean.... |

|---|

|

|

| ...apply the FIPG. |

|---|

|

|

| Tighten the 9 bolts to 34 ft/lb per the fsm. One of the 9 is a hidden bolt. |

|---|

|

|

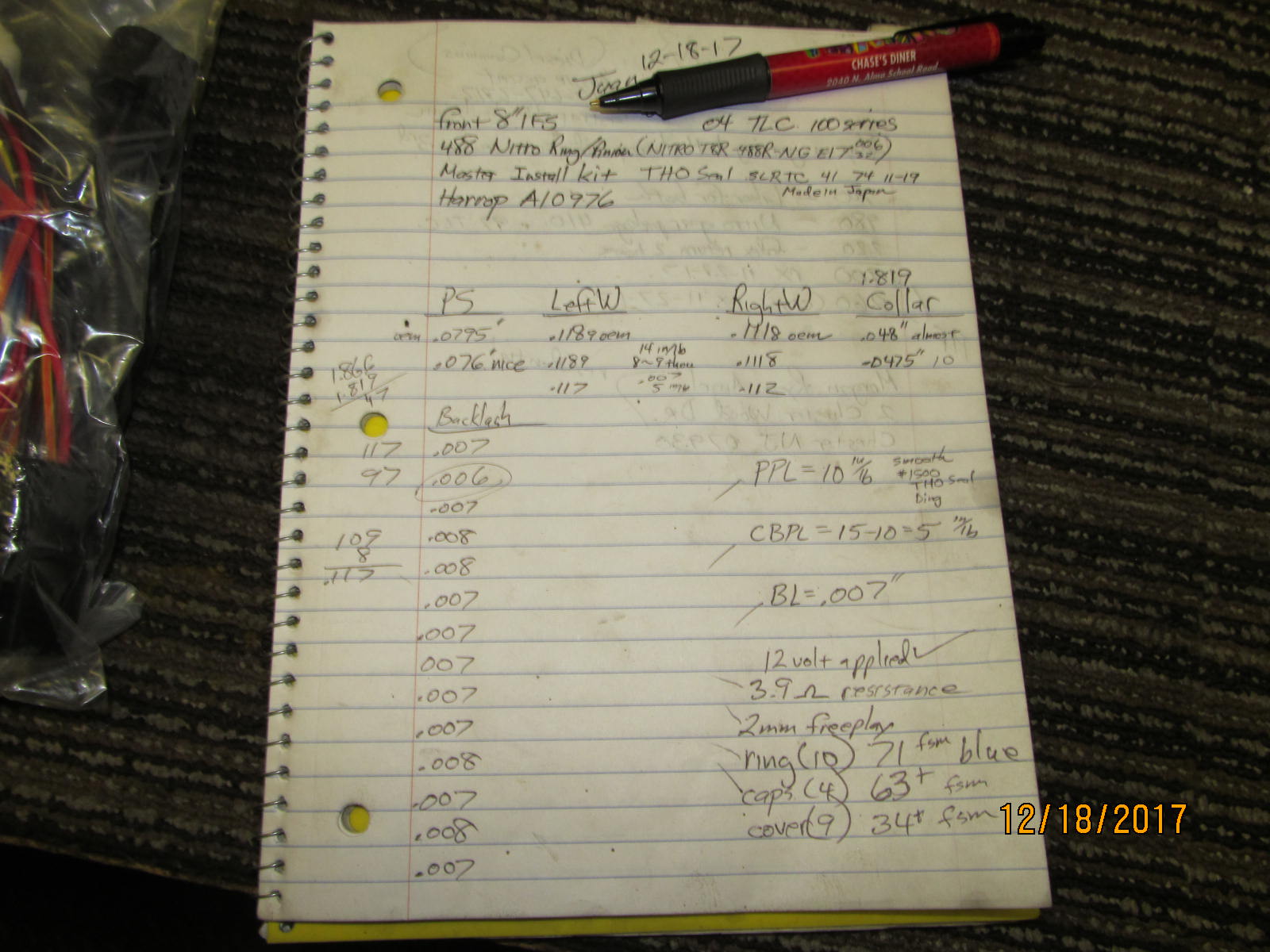

| My notes of the install of the 488 gears and the Harrop. |

|---|

|

|

| Ready for the trip back to Alabama. |

|---|

|

|

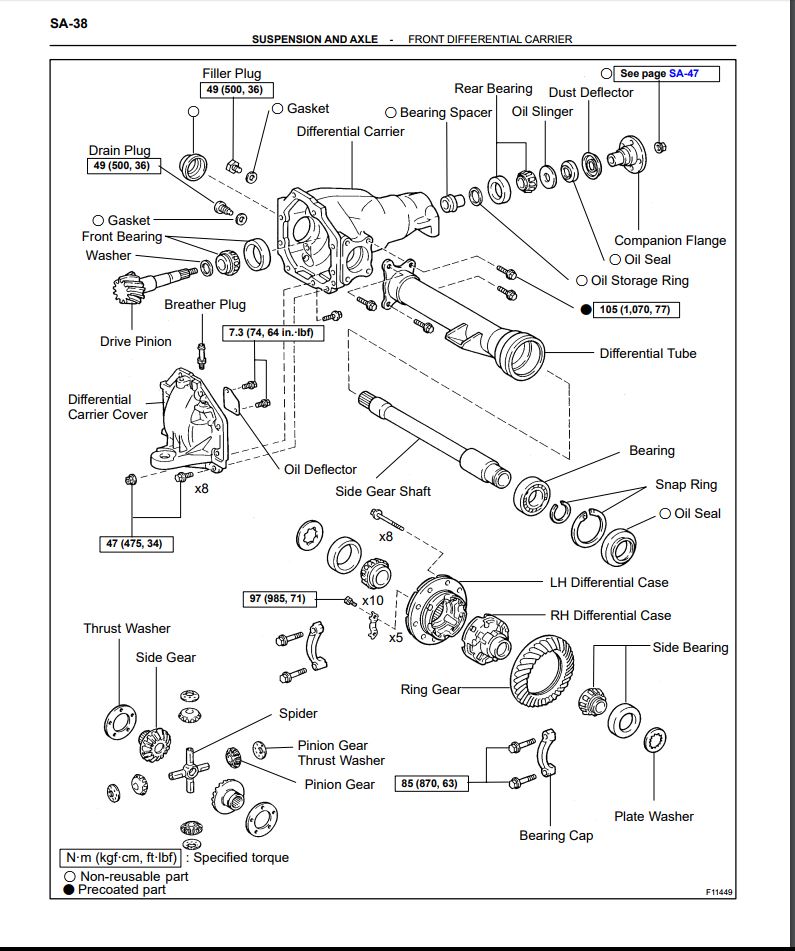

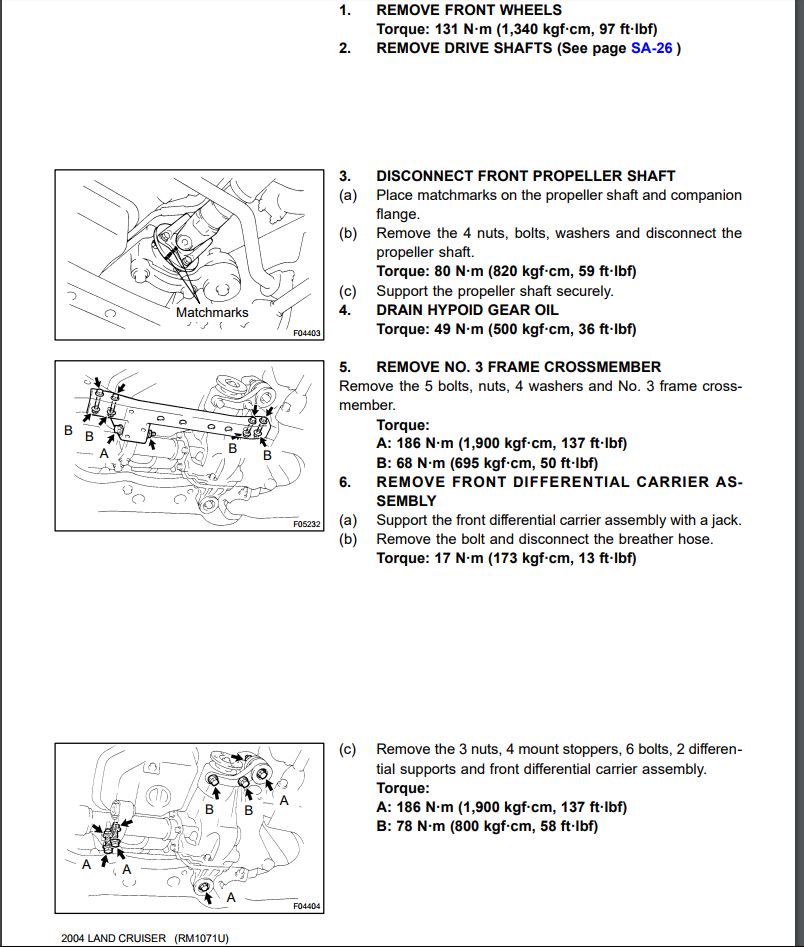

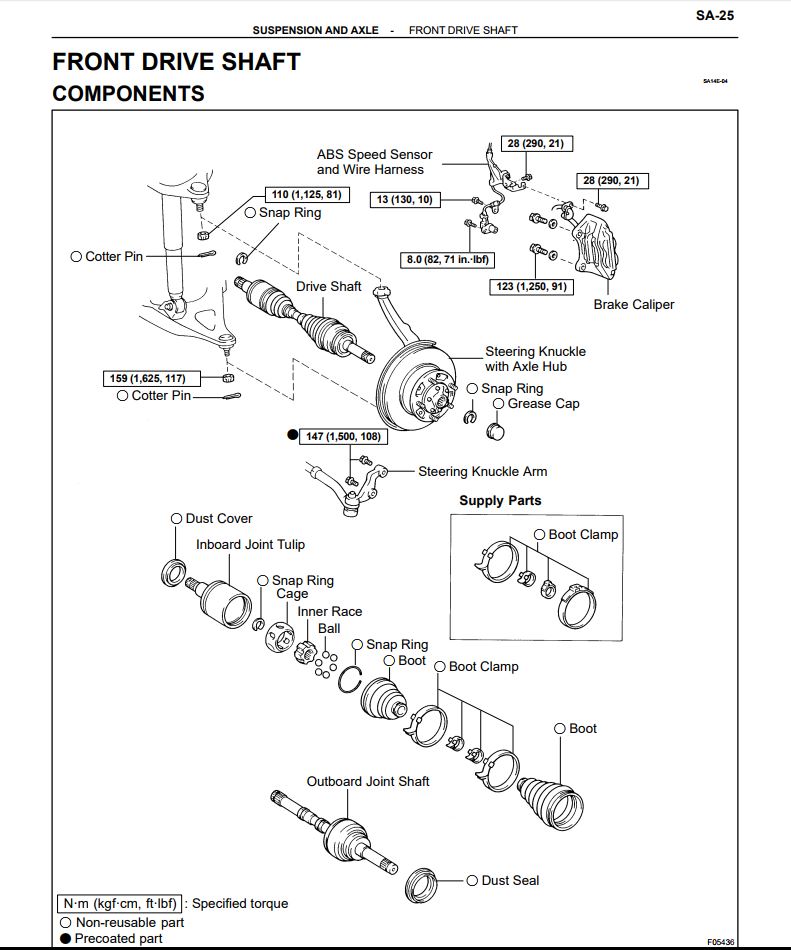

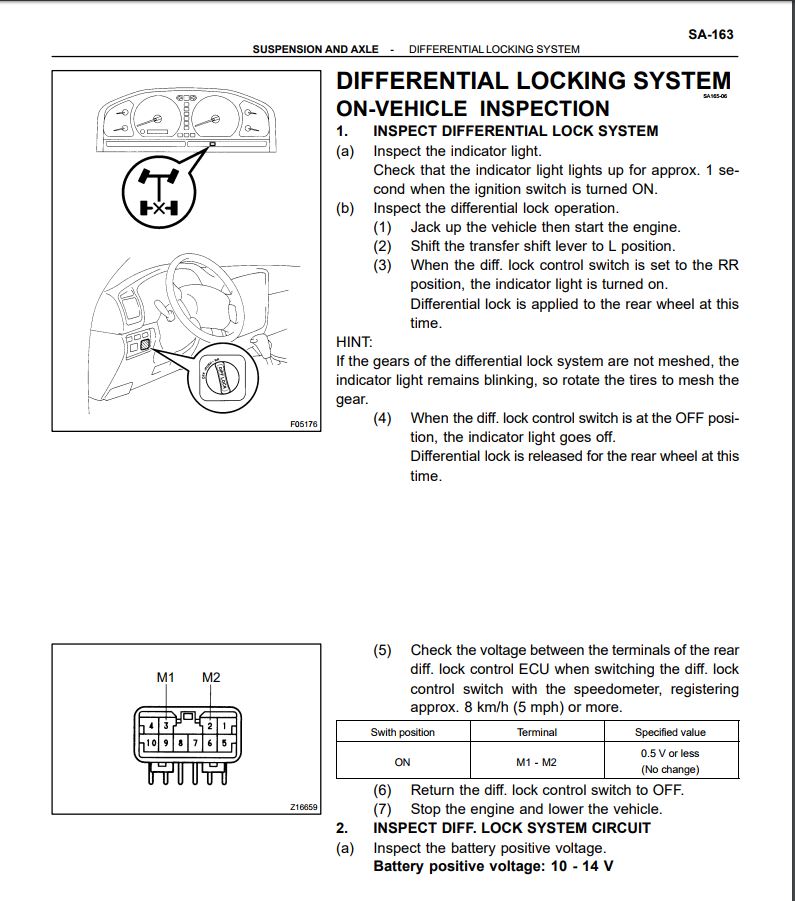

| Some fsm pages of the 8" IFS that I would like to share. |

|---|

|

|

| |

|---|

|

|

| |

|---|

|

|

| |

|---|

|

|

| |

|---|

|

|

|