| Local NC Landcruiser install goes bad fast...."ZUK, can you dissect the install and give it a proper set up?" |

|---|

| (87 BIG pics loading) |

|---|

| AUGUST 20 2018 |

|---|

|

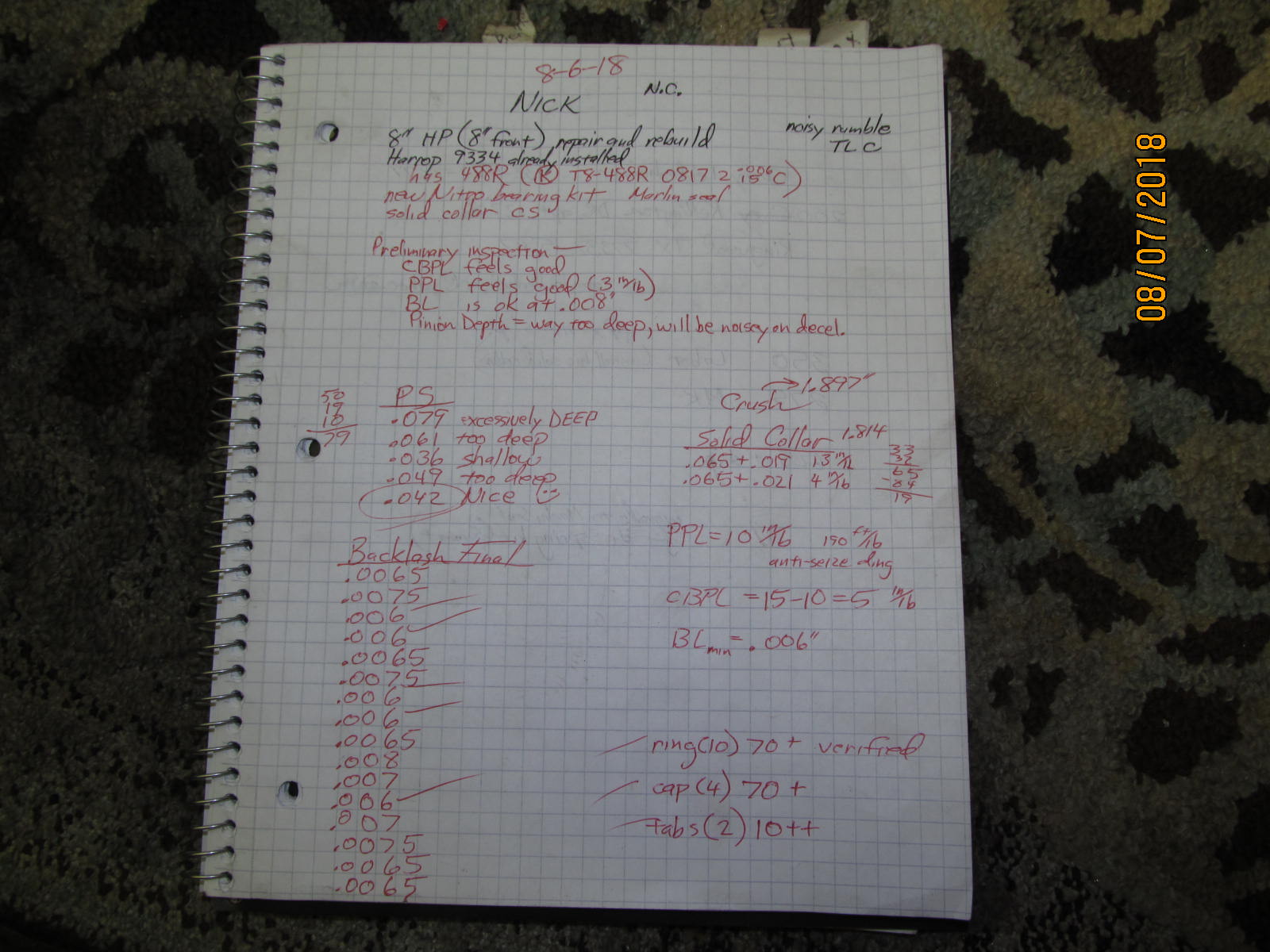

Nick, out of North Carolina, had "a friend of a friend of a friend" do his front FJ80 install. Only 20 miles of easy break-in and the 3rd

starts making a loud noise. A few emails and 5 days later, I receive the box. |

|---|

|

|

| A nice job of cushioning the 3rd in all planes. |

|---|

|

|

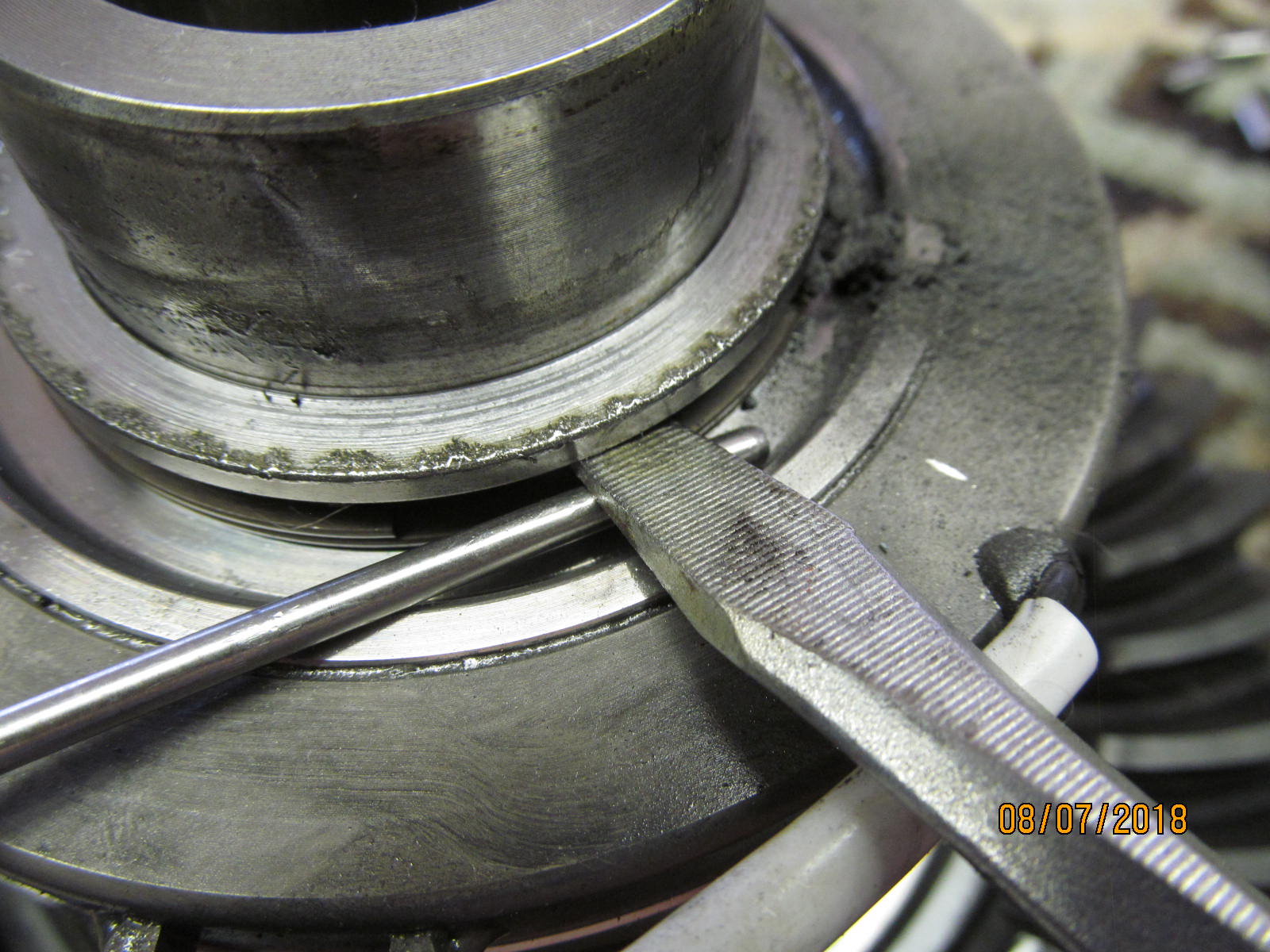

| Initial inspection shows too much thread exposed. This basic style of nut requires a thick hardened washer and that was missing. |

|---|

|

|

| Some damage to the bottom of the nut and the once new triple drilled flange. |

|---|

|

|

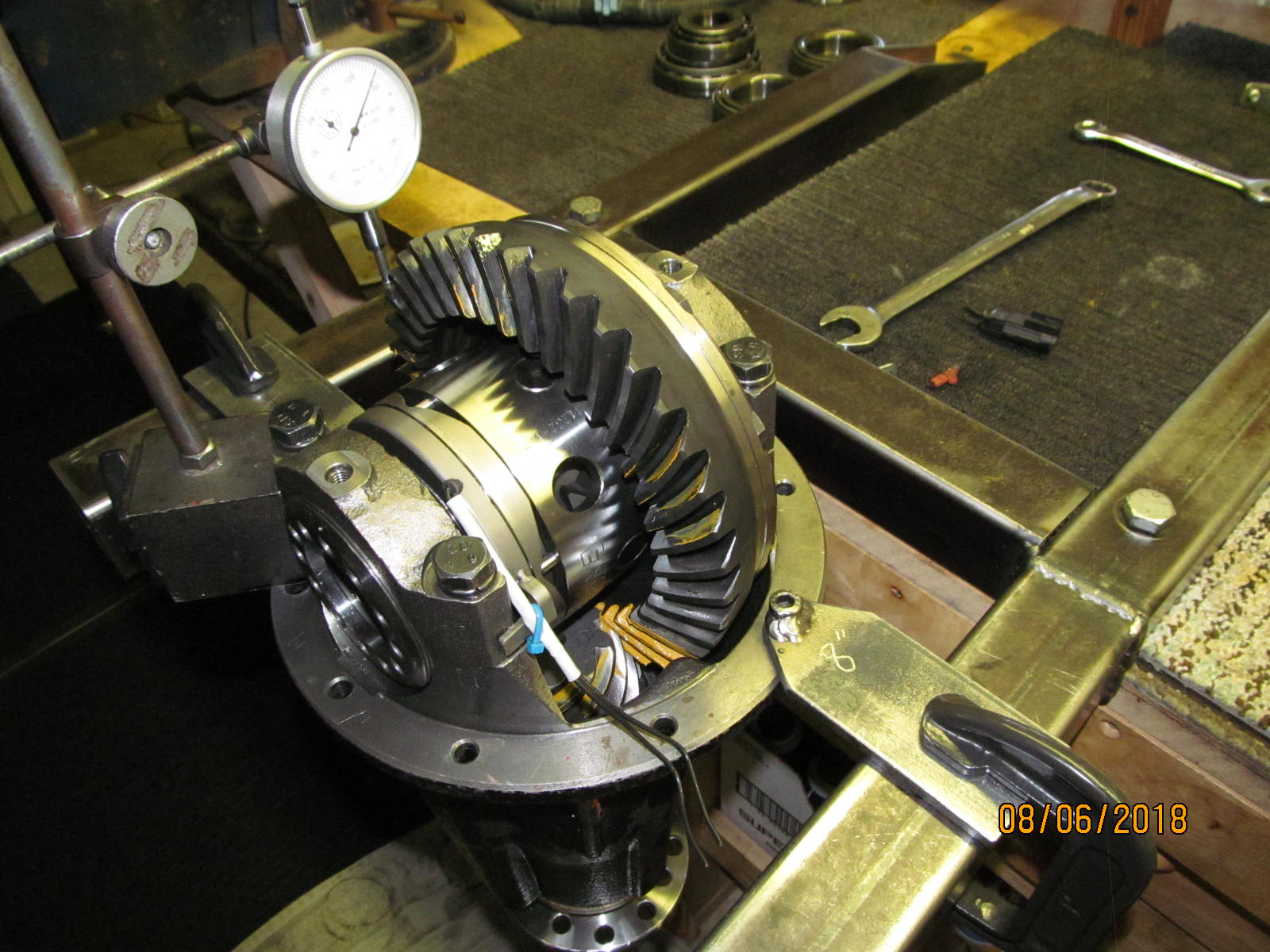

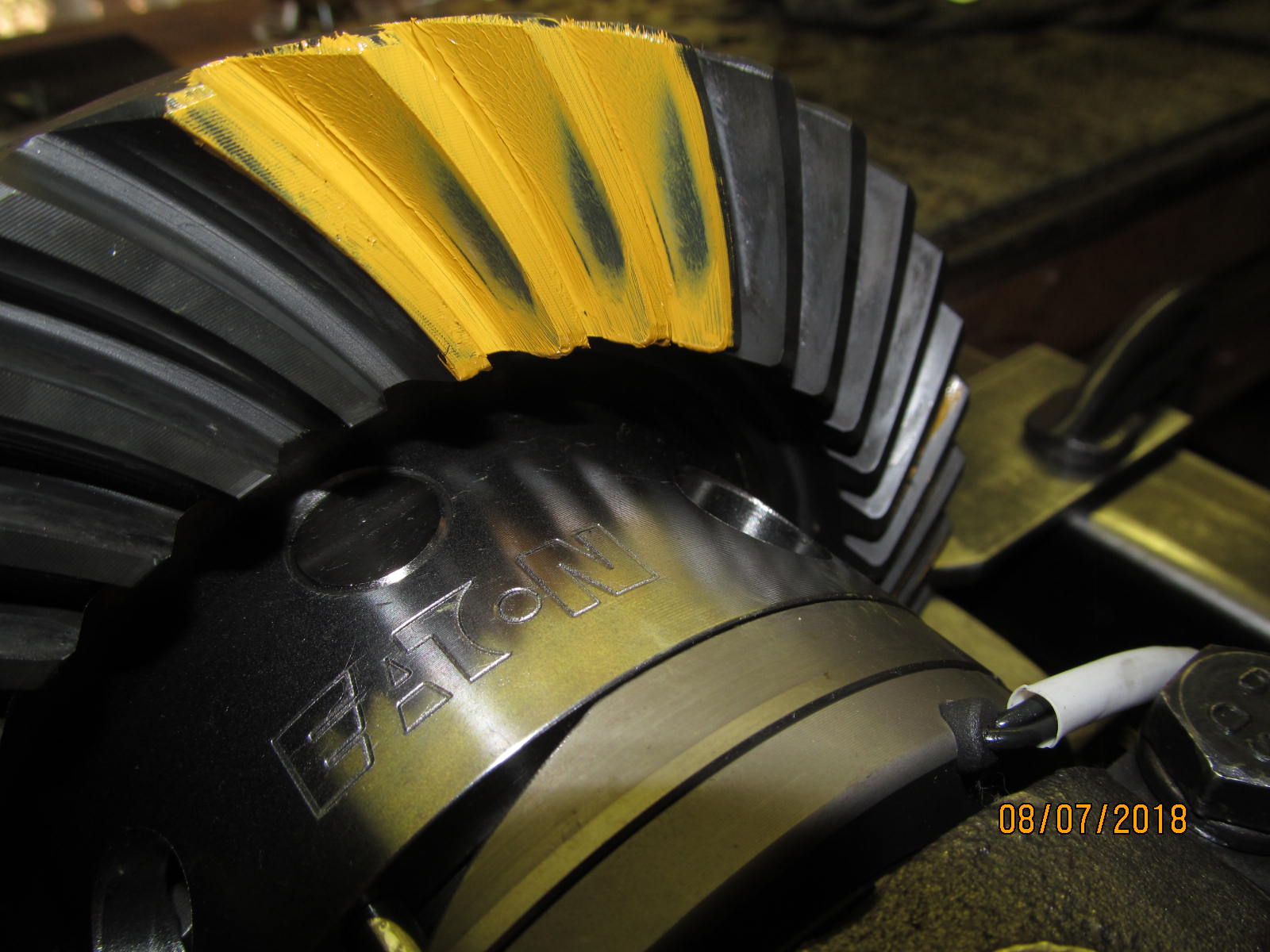

There were no paint marks from the original install so not sure how anybody can even call that a gear install but I did paint the teeth

here and this drive side shows wayyyyyyyyyy deep. The pinion shim is much too thick and not casually so. |

|---|

|

|

| Coast side....terribly deep also. |

|---|

|

|

Backlash was actually in spec though.

Nothing too special to say about the bearing preloads....they were not wobbly and seemed normal. |

|---|

|

|

| Pinion tooth has the contact on the extreme tip/edges. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| Guess I won't be re-using that nut again. |

|---|

|

|

| The flange's sealing surface looks almost perfect. |

|---|

|

|

| No hardened washer and this is the result. In this case, it's mostly cosmetic damage. |

|---|

|

|

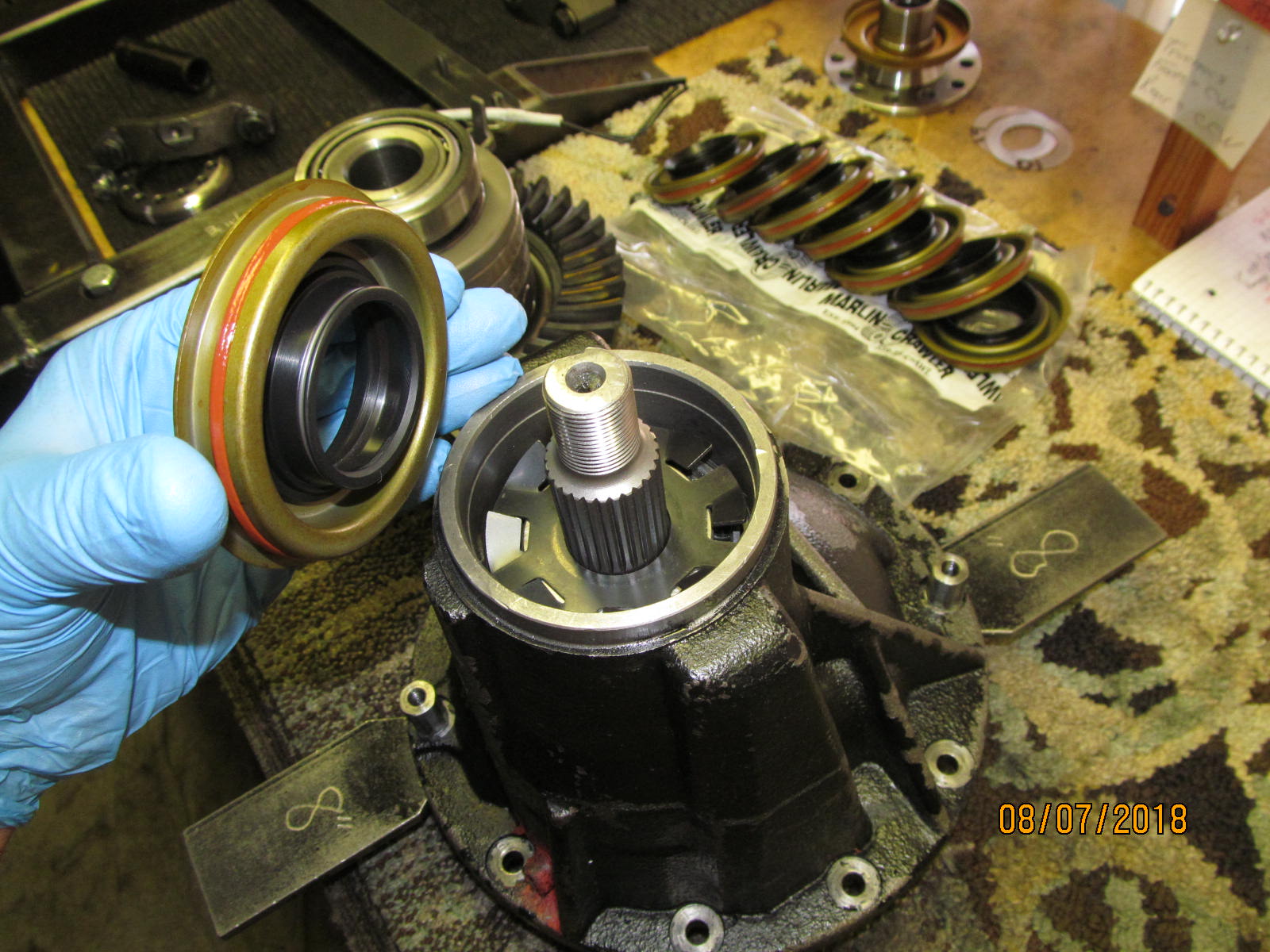

| This was a new 27 spline Yukon seal. |

|---|

|

|

| This bearing and the race look older than the 60 miles put on them and that could be the result of excessive metal debri in the new oil. |

|---|

|

|

| A crush sleeve was used. |

|---|

|

|

| The shim value used was .079" which is a very typical shim. |

|---|

|

|

| A closer look at the small outer pinion bearing/race. |

|---|

|

|

| The large inner race has damage consistent with metal particles in the oil (contamination damage). |

|---|

|

|

| Damage comparisons of the inner and outer pinion bearings. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| ::::::::::::::::::::::::::::: |

|---|

|

|

| The carrier bearings are turning about 5 times slower but have similar damage to the race and bearing rollers. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| ::::::::::::::::::::::::::::: |

|---|

|

|

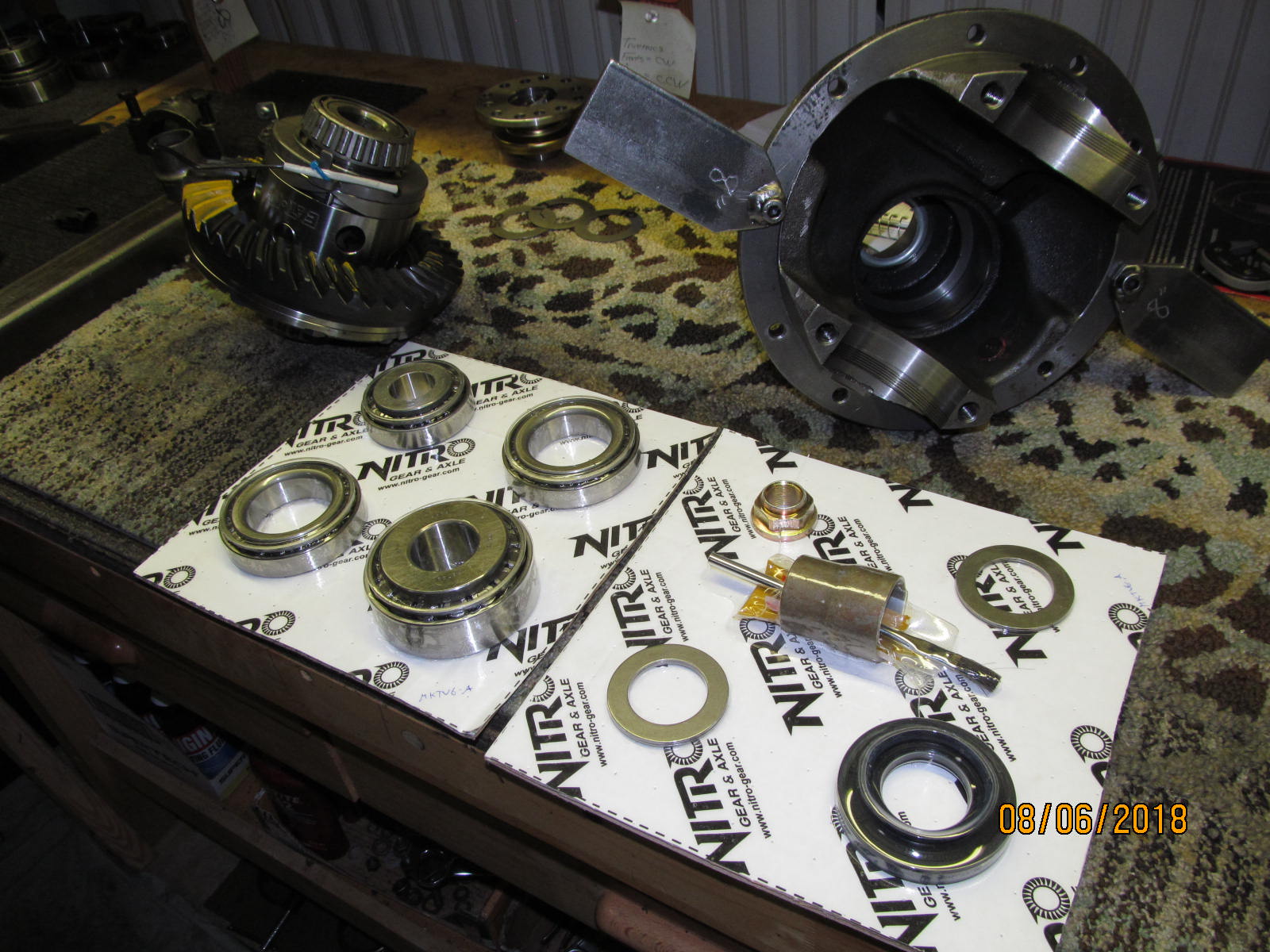

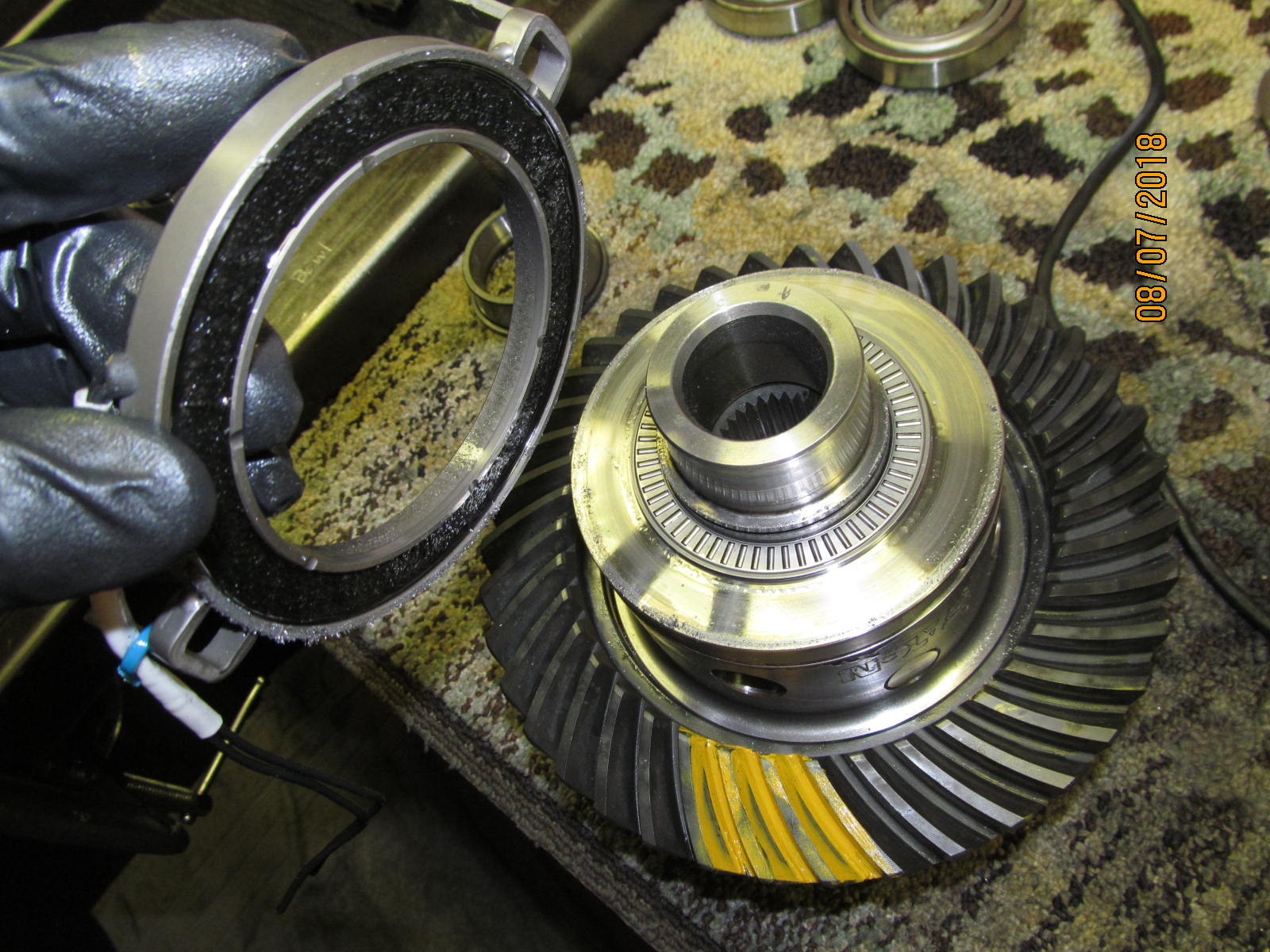

| Out with the old and in with the new.....time for new Koyo bearings from the Nitro kit. |

|---|

|

|

| There was damage to the pinion threads but I had the fix. |

|---|

|

|

| The new nut would now spin on effortlessly. |

|---|

|

|

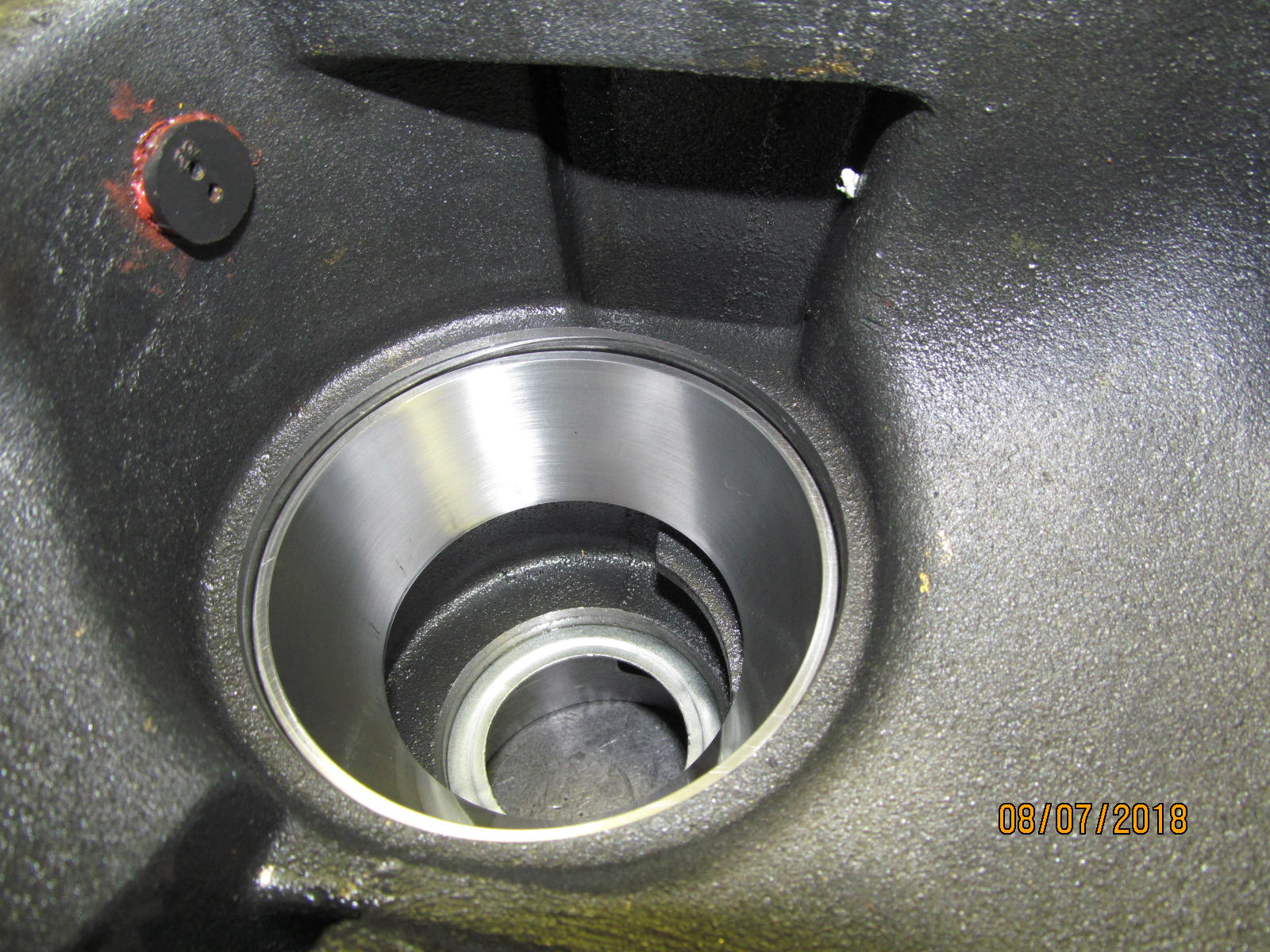

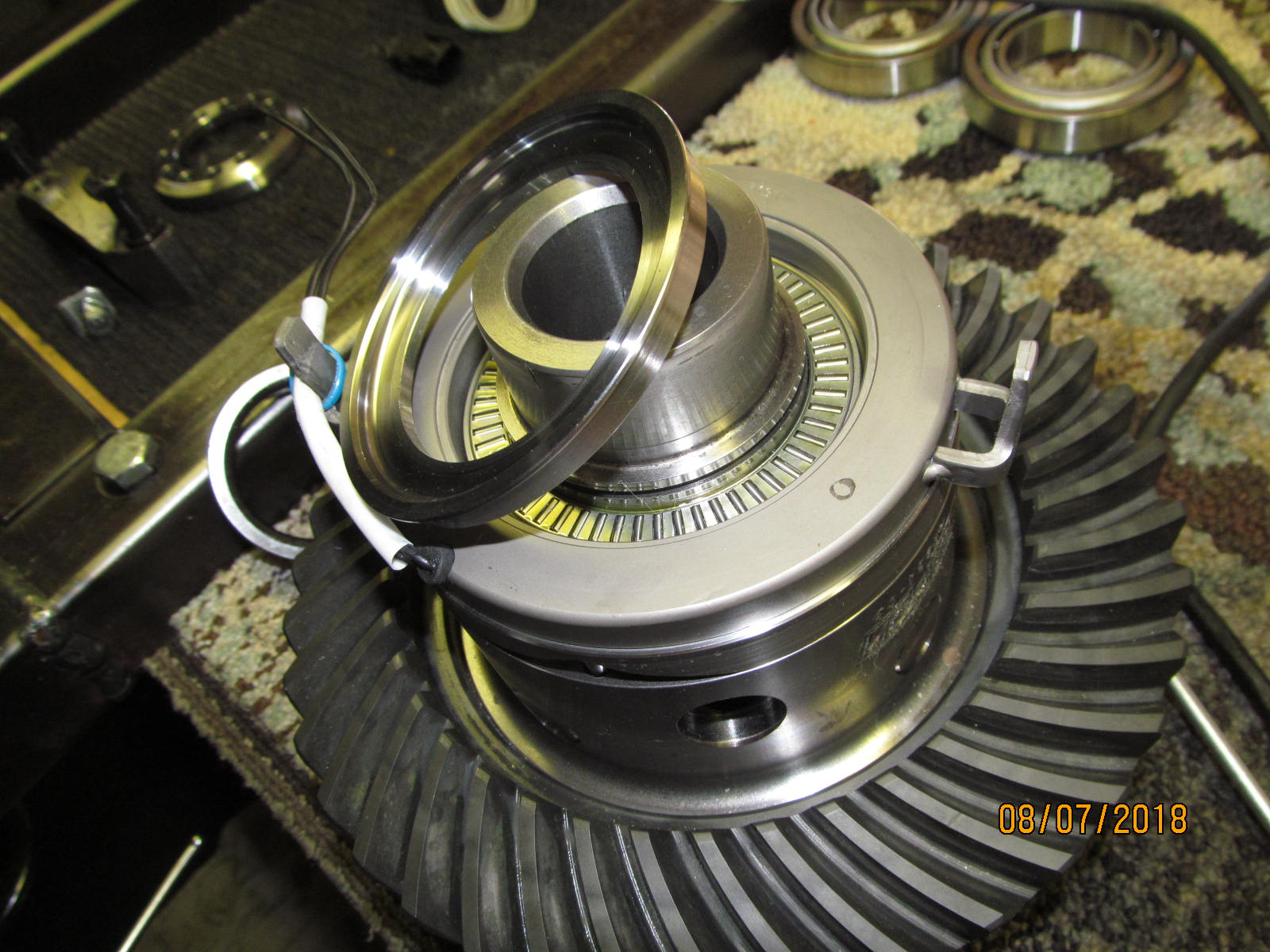

| New inner koyo race tapped in with 360 degree support. |

|---|

|

|

| Same with the smaller outer race. |

|---|

|

|

| Going to try a much thinner .061" pinion shim now. |

|---|

|

|

| The pinion assembly station...... |

|---|

|

|

| Just tight enough to develope about 20 inch/pounds of pinion start torque. |

|---|

|

|

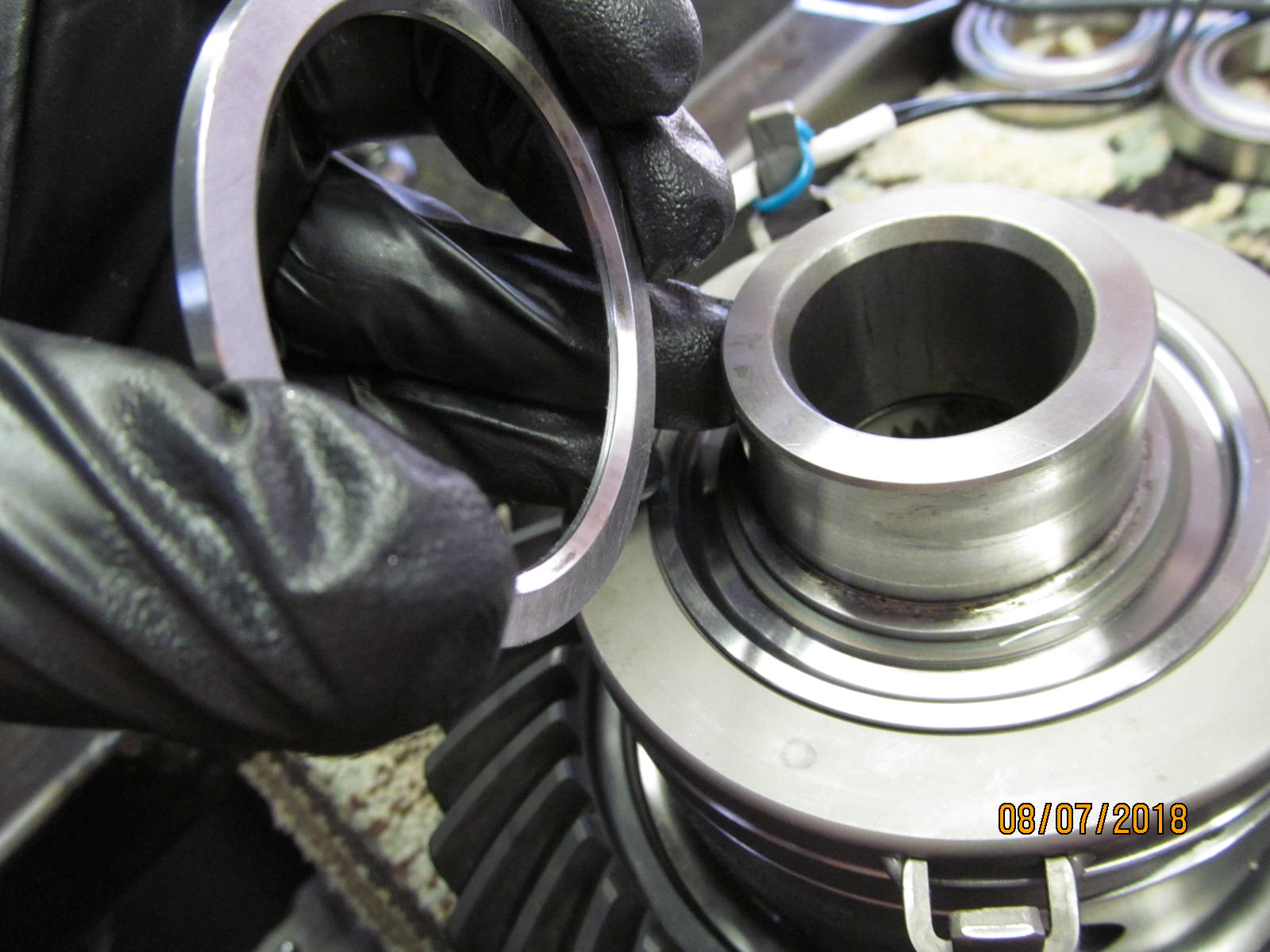

| The design of the journals and surrounding area is such that a puller cannot reach in there and get the bearing off. |

|---|

|

|

| A dremel with a grinding wheel can do it in 5 minutes. |

|---|

|

|

| Bingo! |

|---|

|

|

| Easy peasy. |

|---|

|

|

| To the garbage can. |

|---|

|

|

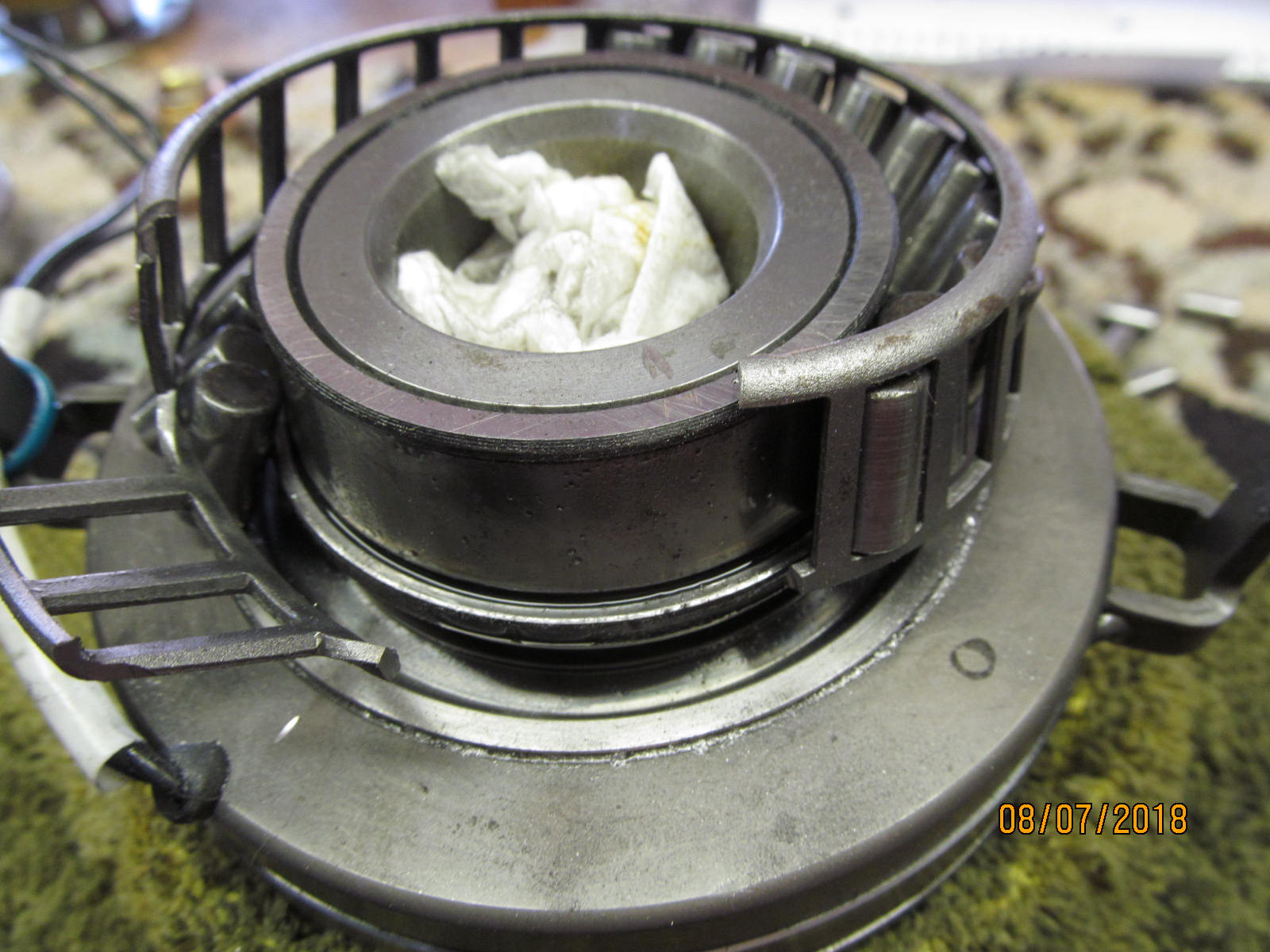

The fine metal mush that the electro-magnet attracted to it in the previous weeks is visible on the inside edge of the grey ring.

I will have to dis-assemble the magnetic body and clean it. |

|---|

|

|

| The cage is removed... |

|---|

|

|

| The inner race is also removed. |

|---|

|

|

| A screwdriver and that "just right" roll pin punch allows the pressed on ring to slowly be worked up. |

|---|

|

|

| A slightly larger roll pin punch allows the sleeve to work up farther.... |

|---|

|

|

| ....until it is free and clear. |

|---|

|

|

| That's not my mess....that's what the electro-magnet attracted to it while the ring/pinion were meshing terribly together. |

|---|

|

|

| 2 small screwdrivers and the coiled clip can be worked loose. Kind of like taking a tire bead off a wheel. |

|---|

|

|

| It's free. |

|---|

|

|

| Yucko....this is why I had to take it apart and clean it. |

|---|

|

|

| Everything is totally undamaged and the particles will be blasted off thoroughly with my favorite sauce.....pressurized starting fluid. |

|---|

|

|

| This needle bearing might be considered the wear item with all that debri in there....but it will be squeaky clean when I get done. |

|---|

|

|

| This "ramp ring" gets cleaned also. |

|---|

|

|

| cleaned and oiled up. |

|---|

|

|

| /////////////////////// |

|---|

|

|

| Coiled spring is easy to reseat it.....start here and work 2 screwdrivers around. |

|---|

|

|

| Lastly, the sleeve retainer. |

|---|

|

|

| I found that just right bearing "widget" and lightly tapped the sleeve down til it was seated 100%. |

|---|

|

|

| 100% down. |

|---|

|

|

| Now the new Koyo TR100802-2 bearing is tapped on. A nice, tight fit at that. |

|---|

|

|

| This section is now complete. Now to load this Harrop into the 3rd and paint a few teeth. |

|---|

|

|

| Drive side 061..........Even with a much thinner .061" pinion shim the contact is still too deep. |

|---|

|

|

| Coast 061....way deep still. |

|---|

|

|

| Now to really, really go thin.....25 and 11 makes 36 so let's try .036" shim. |

|---|

|

|

| Drive side 036.....We just overshot it by a little....now shallow. |

|---|

|

|

| Coast 036....shallow. |

|---|

|

|

| Now trying .049" |

|---|

|

|

| Drive side 049....deep now. |

|---|

|

|

| Coast 049....too deep. |

|---|

|

|

| Zero'ing in on it....Driveside with .042" and this is perfect. |

|---|

|

|

| Coast with 042 and it's very nice. A keeper. |

|---|

|

|

| Drive side reverse painted. |

|---|

|

|

| Coast reverse painted. |

|---|

|

|

| Drive side of pinion tooth....comet tail is feathering towards the center(from the root) so it's perfect. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

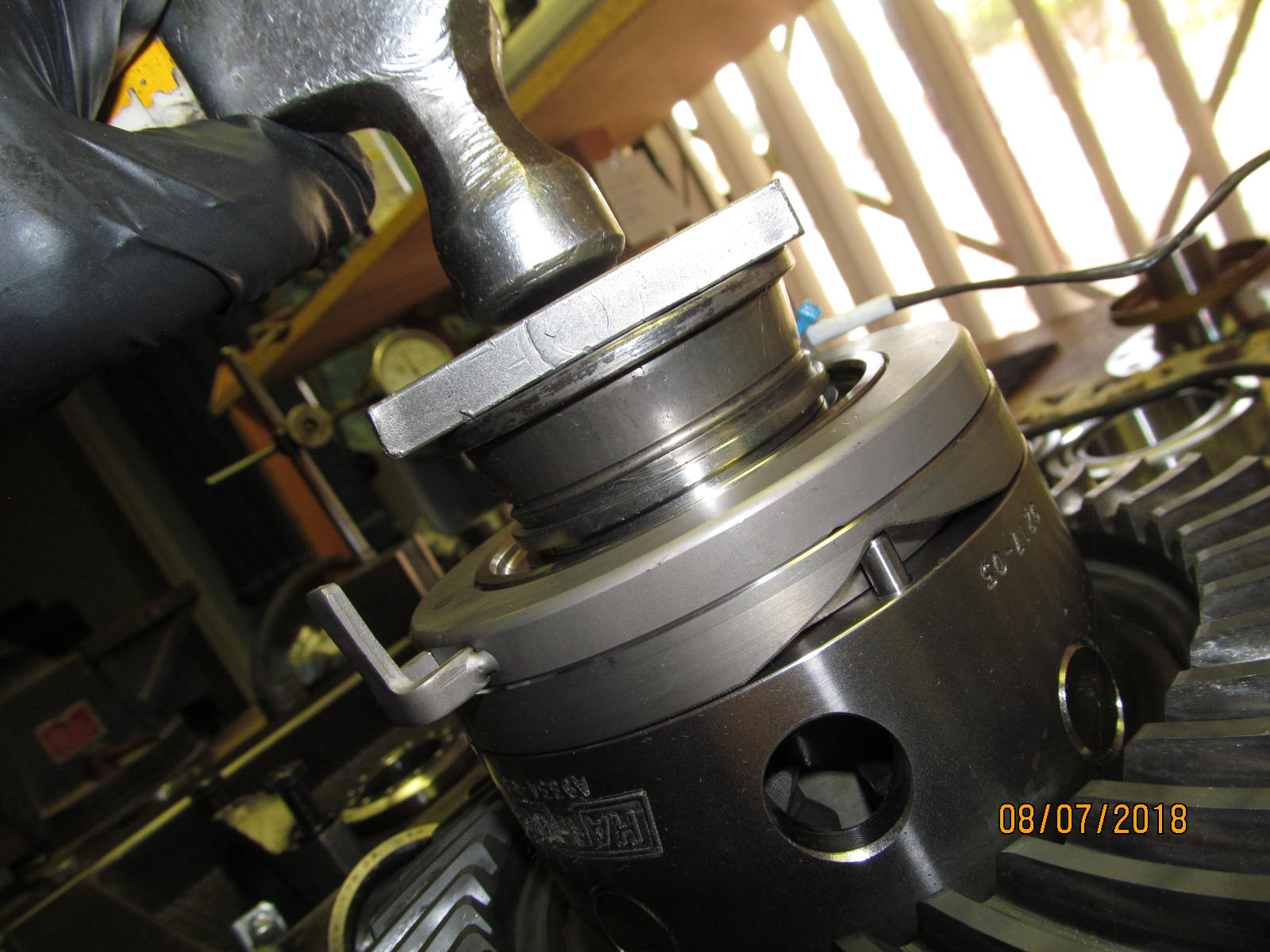

| Solid collar time. |

|---|

|

|

| Most of the time the oil retainer hits the edges of the solid collar. |

|---|

|

|

Leaving out the oil retainer is one way to avoid contact but one could also flare the retainer up a little with this tool.

Looking closely, you can see that the retainer has been flared up by using this tool on the bottomside. |

|---|

|

|

| That, in combination with some relief on these abrupt edges, allows for plenty of clearance. |

|---|

|

|

| //////////////////////////// |

|---|

|

|

| I got lucky, it only took 2 tries to get the collar shimmed correctly. |

|---|

|

|

| The collar is also clearancing the oil retainer just fine as shown. |

|---|

|

|

| Fan-blade slinger and Marlin Crawler seal time. |

|---|

|

|

| The Marlin seal is the seal of choice for the 27 spline rear Landcruiser 3rds. Oil is applied to the rubber and flange goes on. |

|---|

|

|

| Even with all the lubricating anti-seized used, it still took about 190 ft/lb on the nut to get the desired 10 inch/pounds of pinion bearing start torque. |

|---|

|

|

| Bearing caps are torqued to 70 ft/lb, wheel adjuster are set for carrier bearing preload, and backlash is then recorded on every other tooth. |

|---|

|

|

| Some specs are inscribed. |

|---|

|

|

| Lastly, the tabs are torqued to 10 ft/lb |

|---|

|

|

The wiring was a little short so I offered to extend them about 6 inches.

I have 2 solder certs from Hughes Aircraft Company Tucson AZ so I put that skill to use ;)

mil-std-2000 |

|---|

|

|

| |

|---|

|

|

|