| Rip upgrades his 03 Tacoma front clamshell with a 911A644 Truetrac and cryogenically treated bearings. |

|---|

| (55 BIG pics loading) |

|---|

| DEC 5 2017 |

|---|

|

| Rip 2003 1st gen Tacoma sees some unusual duty. |

|---|

|

|

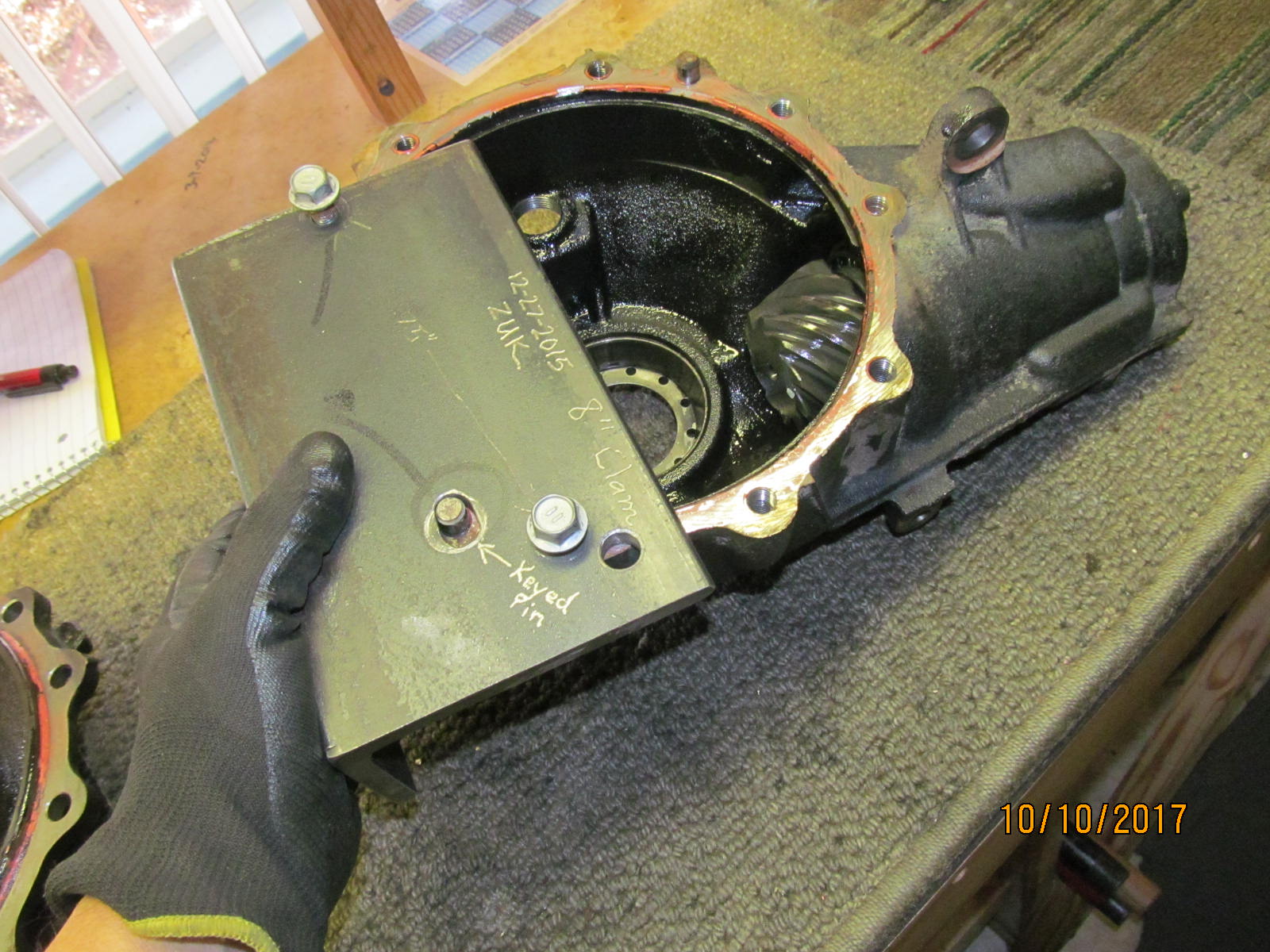

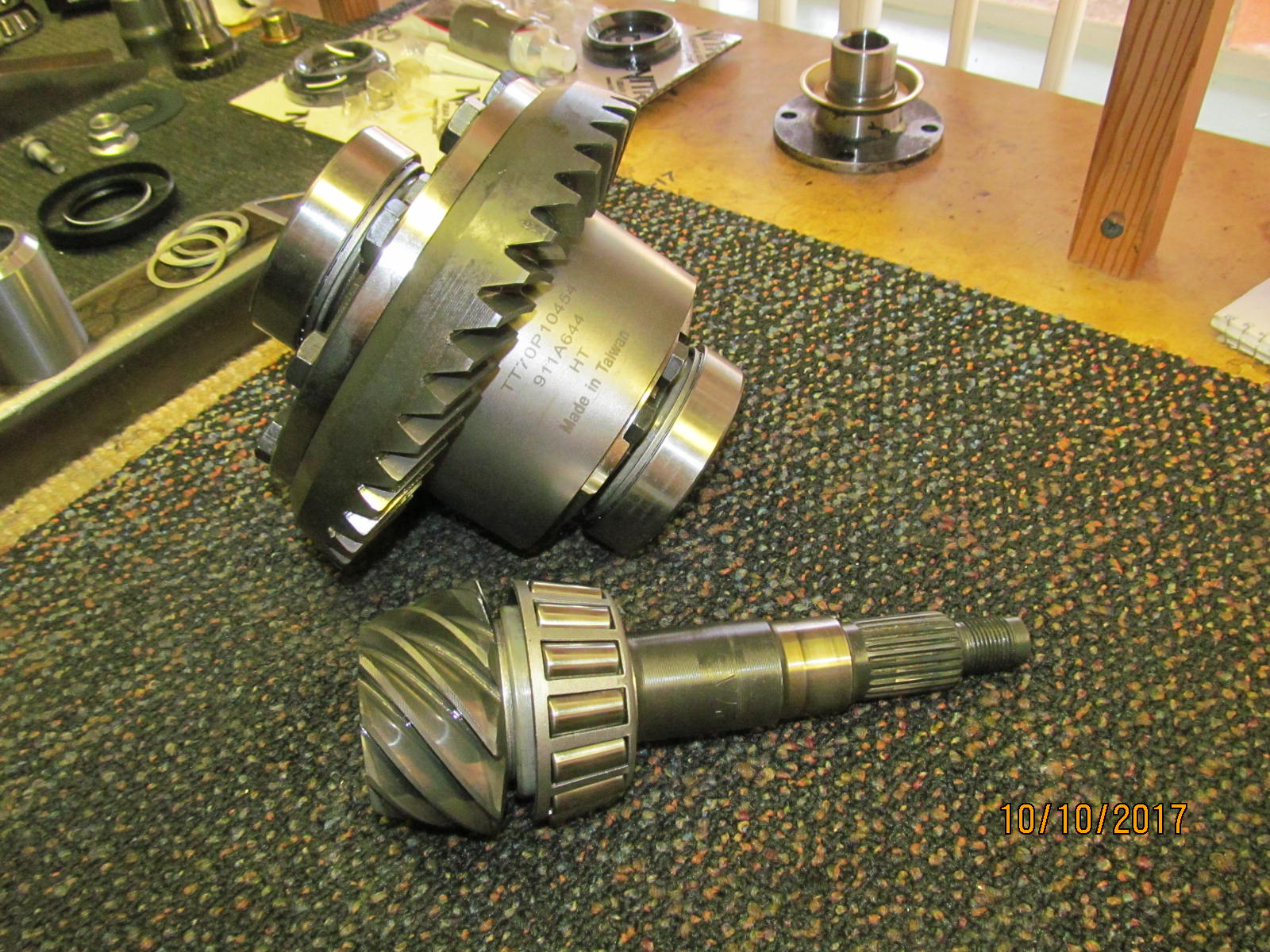

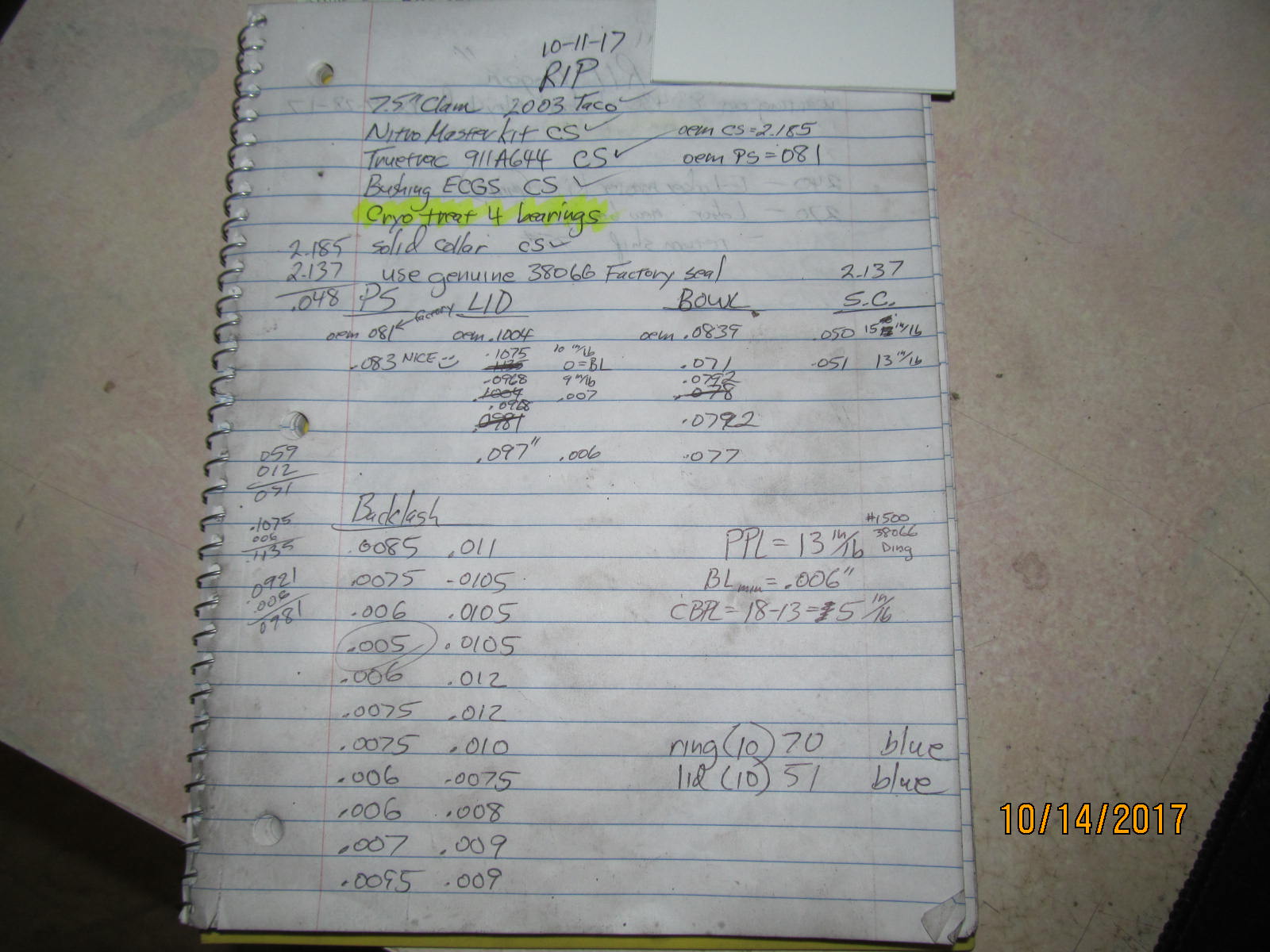

The front 7.5" clam and the rear 8" V6 style diff are seeing rebuilds. The front will see a 911A644 Truetrac and new bearings

that will be cryo treated. |

|---|

|

|

The bearings from both master kits were delivered to Cryogenics International which is located in Scottsdale, AZ.

This is the smaller chamber that will be used for Rips' 8 differential bearings. Numerous other items are being cryo'd also.

Even these 4 drive belts for side by side UTVs are to be cryo'd.

Wouldn't you cryo a 3 pound belt that originally cost $125 for 30 bucks if you

found out in testing that they were lasting 3 times longer?

The reason they last longer?...in 2 words, Carbon Fibers. |

|---|

|

|

| This just arrived... |

|---|

|

|

| The front 7.5" clam with factory 430 gears that will be re-used. |

|---|

|

|

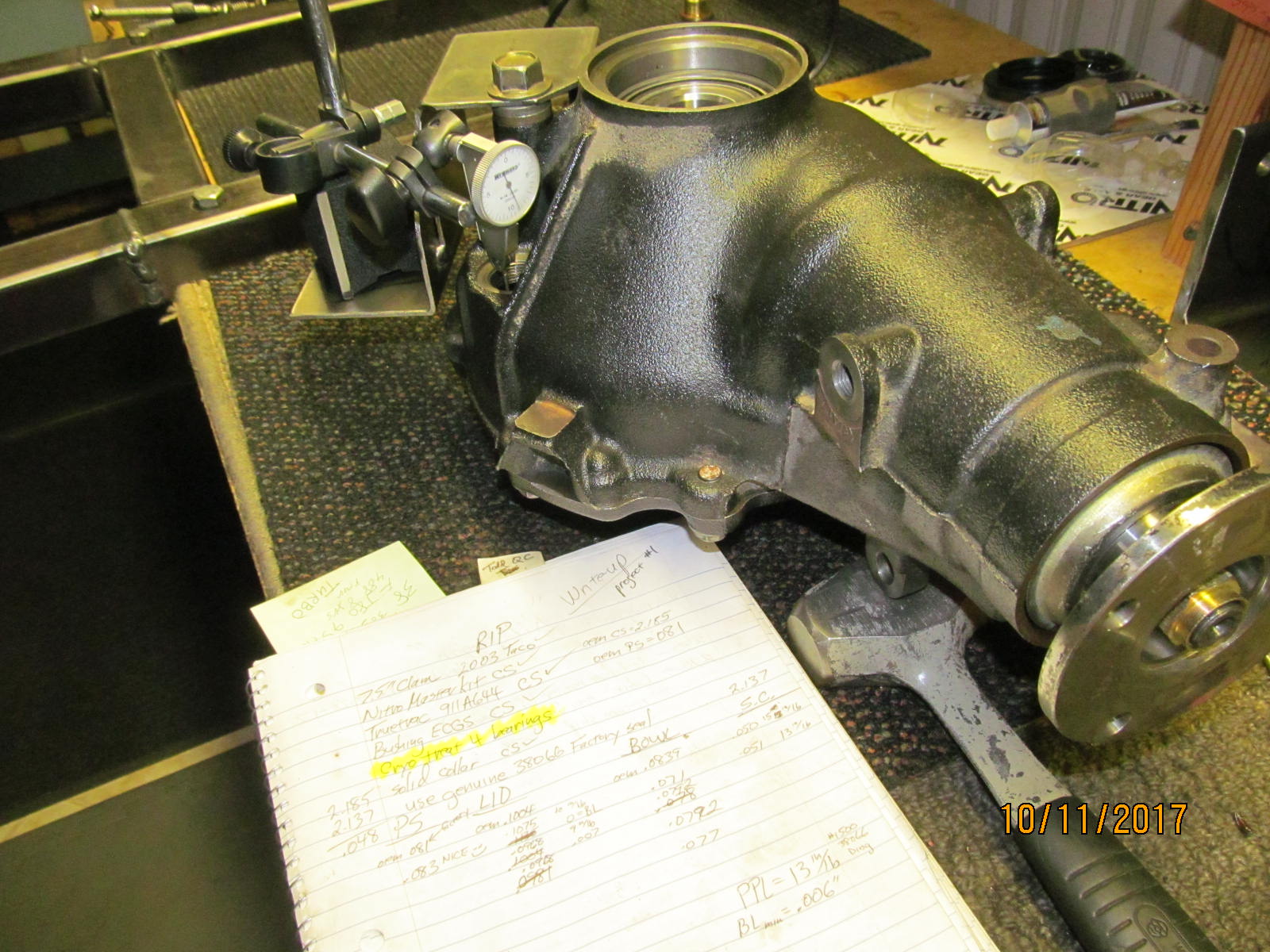

So, here's both diffs that will be rebuilt....the V6 diff in the background will see the cryo bearings and a solid collar.

This write-up is on the front clam.

Here is the brief write-up on the rear 8" elocker HERE |

|---|

|

|

| Got the bearings back from Charles. A proven bearing....Koyo. And this cryo process just made them that much better. |

|---|

|

|

| Everything is layed out. |

|---|

|

|

The box for the Truetrac says A342 and the TT unit has etched on it A644.....

Apparently, they revised the unit and still have a lot of old boxes laying around. |

|---|

|

|

| The easiest way to get the driverside stub axle out..... |

|---|

|

|

| ....is go in from the other side. |

|---|

|

|

| Find that "just right" skinny screwdriver and tap it out. |

|---|

|

|

| ,,,,,,,,,,,,,,,,,,, |

|---|

|

|

| Out it comes. |

|---|

|

|

| Hmmm. Mostly normal with a few pieces of shrapnel that makes me wonder. |

|---|

|

|

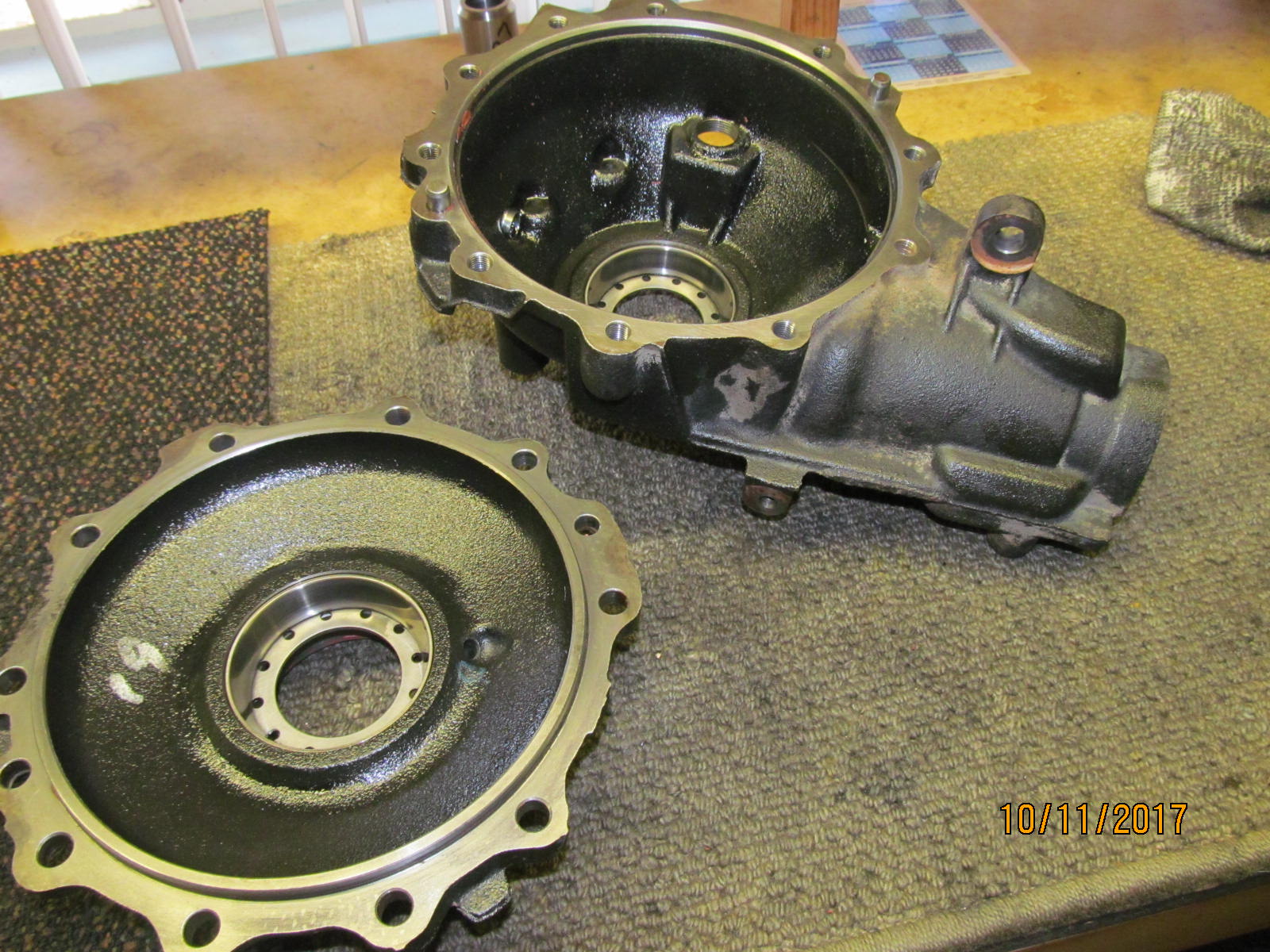

| Remove the 10 bolts from the lid side and separate the halves....Lid on the left and Bowl on the right. |

|---|

|

|

| Really is a 430 gearset....the ring gear has a light stamp mark. |

|---|

|

|

| Remove the flange. |

|---|

|

|

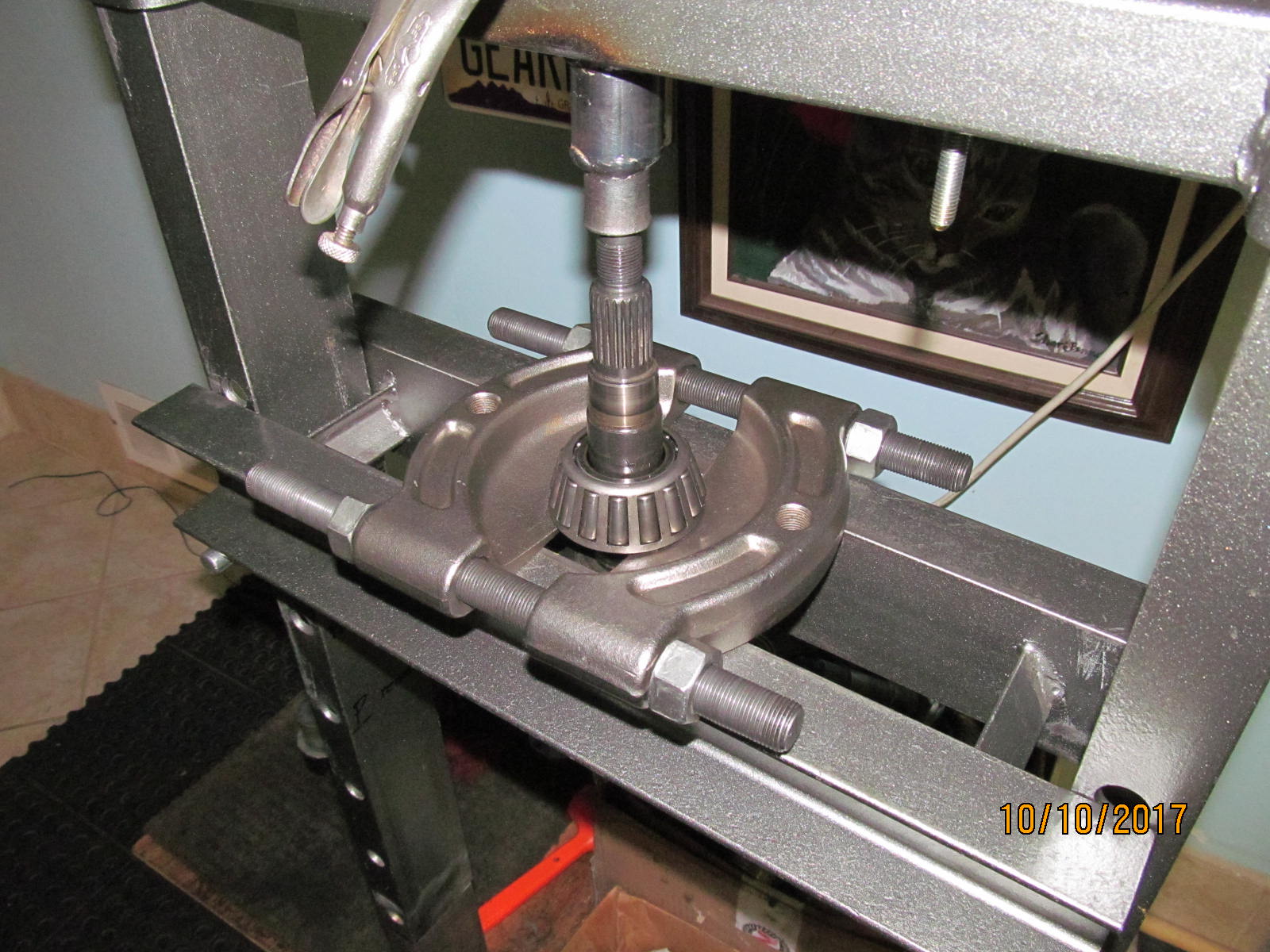

| This piece of angle iron makes the clam more friendly in the 12 ton press. |

|---|

|

|

| It really takes a minimal force to get the pinion to drop out. |

|---|

|

|

| Remove the old bearing from the 430 pinion. |

|---|

|

|

| The new cryo treated bearings goes in its place. |

|---|

|

|

| The new cryo bearing is pressed on. |

|---|

|

|

| Both the Truetrac and the 430 ring gear are checked with a file for burrs or high spots and all was good here. |

|---|

|

|

| The Nitro master kit comes with new ring bolts so let's use them. |

|---|

|

|

| Tap tap and the ring eventually seats itself down. |

|---|

|

|

| Blue Loctite and 70 ft/lb on all 10 bolts. |

|---|

|

|

| The center carrier and the pinion end are ready... |

|---|

|

|

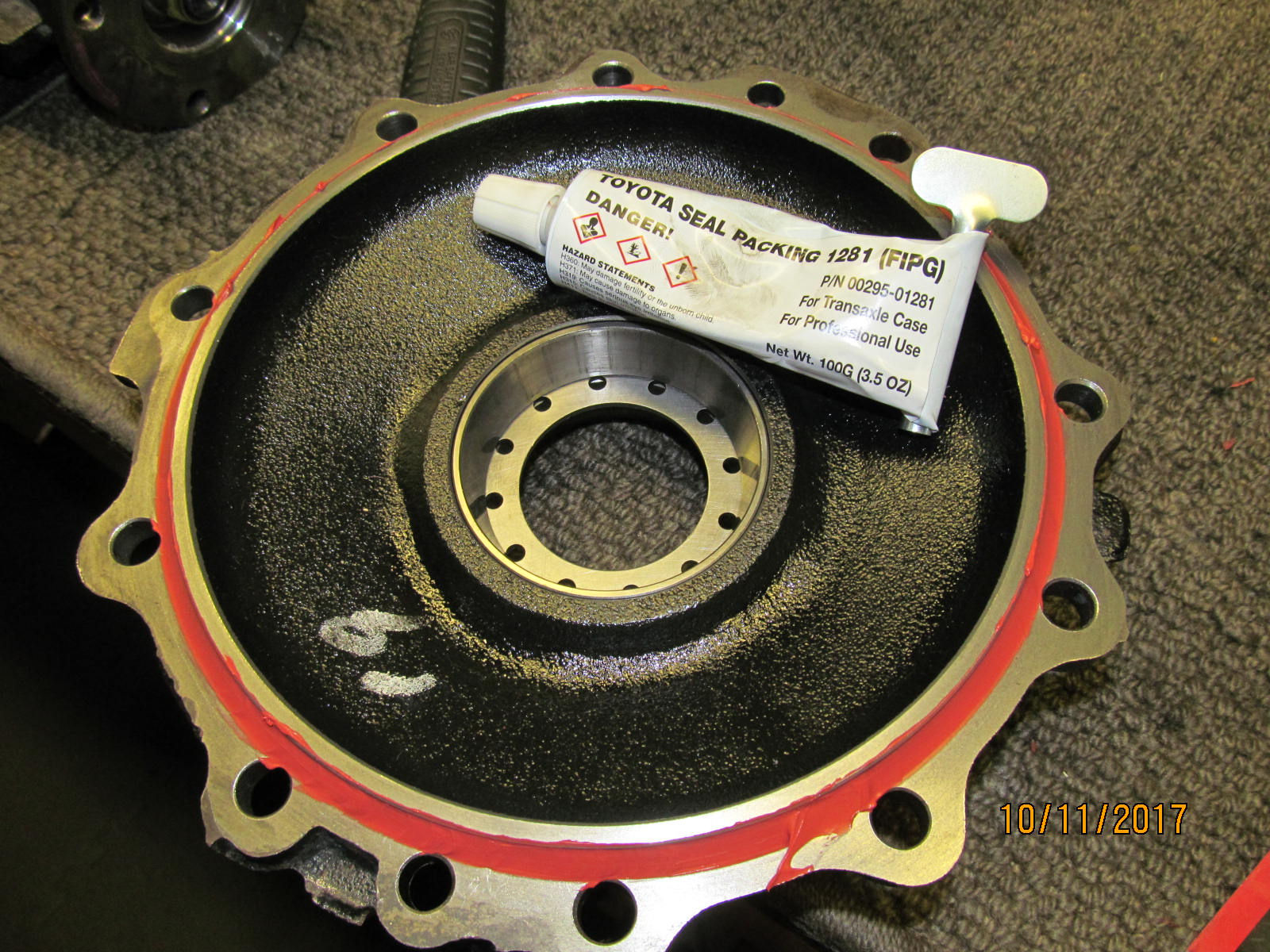

| ...now the bowl and lid need a little prepping. First, to clean the orange FIPG off. |

|---|

|

|

| That's done. |

|---|

|

|

New inner race is going in. They make a special tool to pull the race into position...but I have found it's no big deal if the right hammer is used.

The typical claw hammer does not have enough mass and won't fit in the small space involved. The stubby hammer shown does the job for me. |

|---|

|

|

| Make sure it's started level and true by using a bubble as seen in the pic. |

|---|

|

|

| An old race is used to make sure the new race is driven home 100%. |

|---|

|

|

| BINGO! 100 % seated. |

|---|

|

|

| The outer race is easier. |

|---|

|

|

| A couple of old bearing parts makes the job easy. |

|---|

|

|

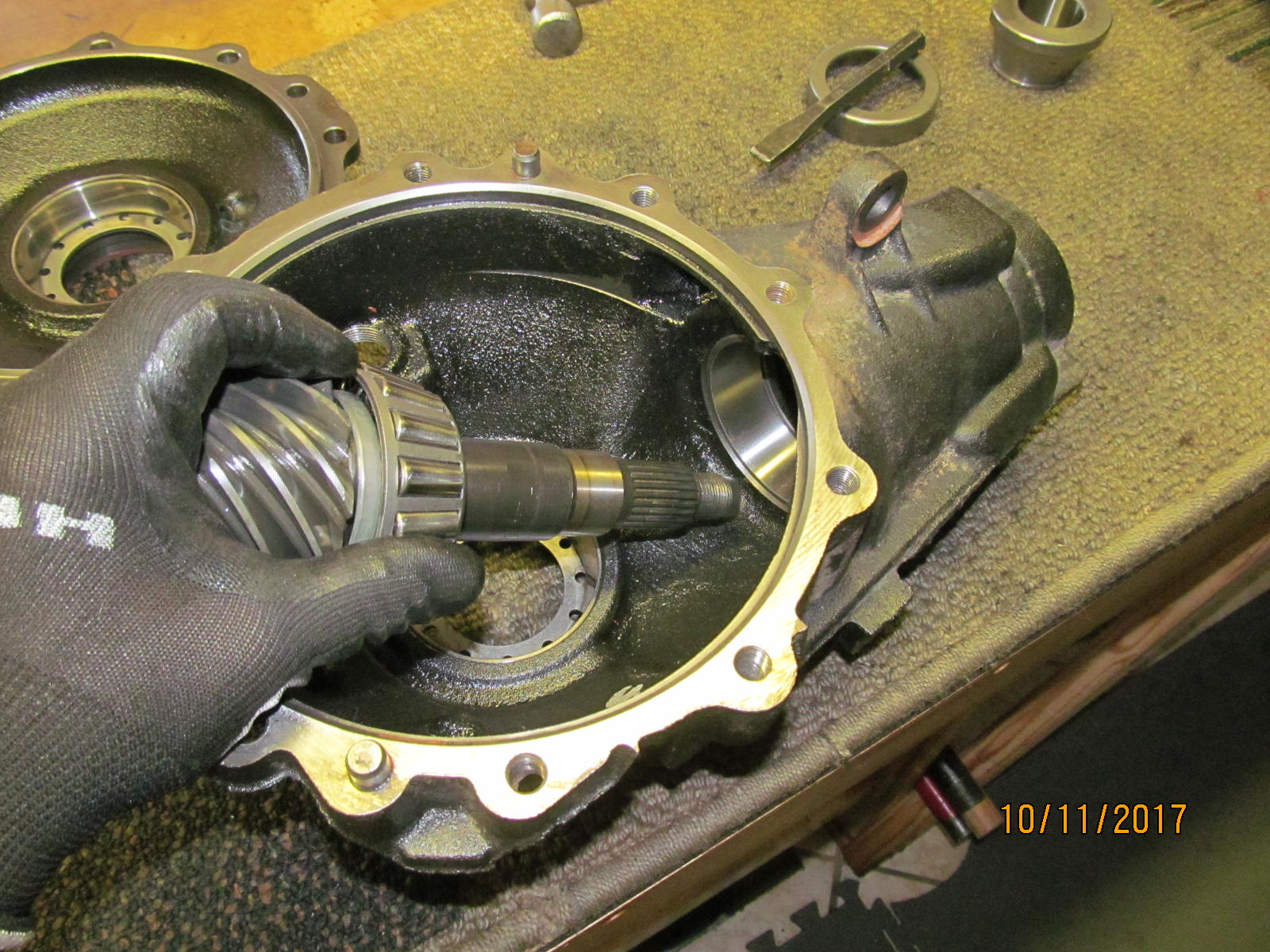

| Load the pinion in the hole. |

|---|

|

|

| The fixture serves double duty here and allows the new outer bearing and flange to be tapped in place. |

|---|

|

|

| The pinion nut was tightened and then used this nice torque meter to measure only a few in/lb of preload. Not enough. |

|---|

|

|

| The pinion nut was tightened just a smidge more and now it measure a healthy 12 in/lb which is okay for the upcoming paint test. |

|---|

|

|

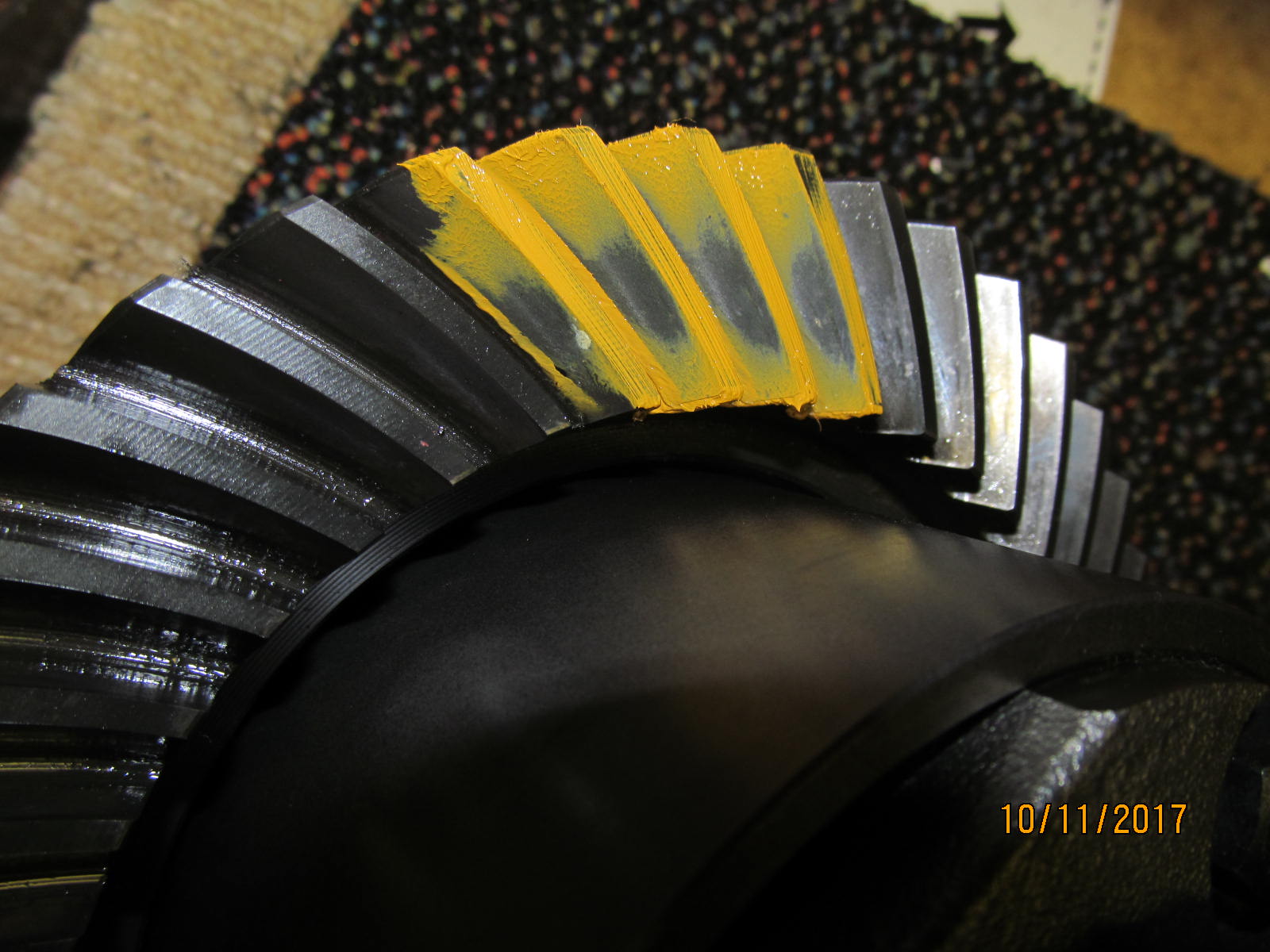

Washer plates had to be change 2 or 3 times to get the right carrier bearing bearing preloads and the desired backlash of about .006".

But as can be seen above, the drive side paint shows shallow so now to add .002" to the pinion shim now. |

|---|

|

|

| Coast. |

|---|

|

|

| It's dis-assembled and press the pinion out. |

|---|

|

|

| It was .081" and now will be .083". |

|---|

|

|

| Now is a good time to install the solid collar. On try #2 the .051" shim did the trick. |

|---|

|

|

| On the 2nd paint check, the pattern was found and looks really good. It is centered and very wide. |

|---|

|

|

| Coast looks good, too. It's centered. |

|---|

|

|

| Comet tail agrees. |

|---|

|

|

| Nice. |

|---|

|

|

| Nice. |

|---|

|

|

| The supplied no-name seal is being upgraded to the genuine factory 38066 pinion seal. |

|---|

|

|

| Backlash is being recorded on about every 3rd tooth. |

|---|

|

|

| This is the recommended sealant for the lid per the FSM. |

|---|

|

|

| 51 ft/lb and loctite on all 10 bolts per the FSM. |

|---|

|

|

I don't recommend that the casual back yard mechanic try setting gears in the clams....in the 7.5" or the 8" or especially the 9" clams......

....unless they have the tooling and washer plates and a little experience at cussing at clams :) |

|---|

|

|

|