|

|

|

|

|

|

Aaron lives on the northwest island of Oahu (Kaneohe, Hawaii). Gear install shops are hard to find here so a call was placed to Marlin crawler and everything, including the hi-pinion carrier, was sent directly to me. |

|

A Detroit EZ locker will go inside the open 4 pinion V6 case. |

|

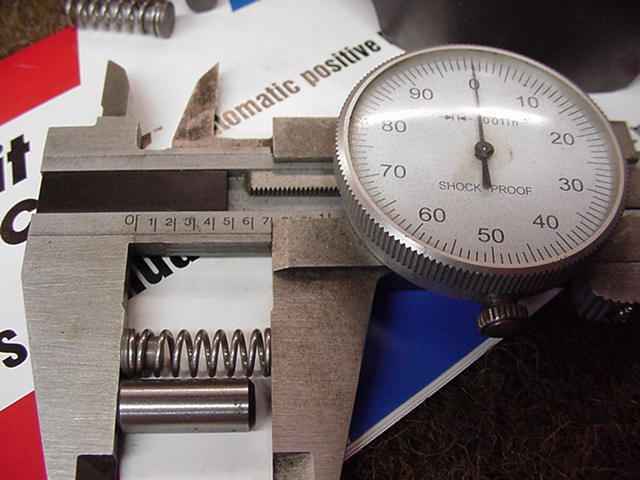

The springs are measured to make sure they are the proper length and they are. |

|

Step one is to remove the 8 cap bolts... |

|

The case splits very easy. |

|

Take the cross out and remove the spider gears. |

|

... |

|

Install the pins and springs. |

|

Apply some grease to keep the pins in when it's flipped over... |

|

... |

|

Now the spacer... |

|

Install the top half of the case. |

|

... |

|

Torque to 45 ft/lb. |

|

Both surfaces are filed to remove burrs. |

|

I use starter fluid to clean all the oils of the threads to prepare them for Loctite. |

|

Tap the ring gear on and torque the bolts to 75 ft/lb. |

|

Most of the time, the carrier bearings can be tapped on with a hammer. |

|

DANG!! I did it again. Now I have to use the bearing puller to free my finger :( |

|

The bearing slipped on too loosely...sleeve retainer compound fixes this. |

|

I will let it set up over-night and will finish this in the morning. |

|

This Marlin Hi-pinion carrier came with the oil retainer already in it. |

|

Both the inner and outer pinion cups tapped in nicely. I loaded up the pinion with

the solid collar and .028" worth of shims.

|

|

The pinion had to be pressed out twice before I found the right solid collar shim value(.026). |

|

I was window shopping at a Harborfreight outlet here and thought I'd see how one of these mechanical digital read-out micrometers would work. |

|

I liked it....only 20 bucks. |

|

.080 pinion shim.....drive side...too deep |

|

coast side |

|

Tear down the 3rd...press the bearing off...re-assemble with a 075 shim. |

|

This time I will apply an excess of anti-seize on the threads. This prevents thread damage and makes it easier to get the right CBPL value. |

|

drive....nice. |

|

coast. |

|

Time to crank on the bearings...I opened the backlash up a little from 6 thou as shown on the above pic to 8 thou as shown below. By doing this, the drive and coast might have a better balance relative to each other. |

|

Nice....it pulled the drive pattern in the center.... |

|

almost no effect on the coast. |

|

Hi-pinions need all the help they can get as far as getting oil to the outer pinion bearing. This oil slinger helps. |

|

Maybe the rtv is not needed....but it seems to allow the seal to tap on a little easier and it might prevent a slow leak around the perimeter of the seal. |

|

Apply gear oil to prevent a dry start-up. |

|

Plenty of loctite on the clean threads and just as much leverage ;) |

|

... |

|

$122 for the trip to Kaneohe :) |

|

In appreciation, Aaron sent some Kona Coffee....how could I refuse? This stuff is some of the best.

Thanks Aaron! |

|

Aaron sent these 2 pic to me a couple of weeks later. |

|

:) |

|