|

Middle of 2005, Bob picked up a V6 3rd with 529 with Detroit SoftLocker

for one heck of a deal...almost given to him ;)....and an 18 pack of beer to boot!

Anyways, right from the very start, the diff was running noisy. Still, Bob

enjoyed the low 529 gearing and got about 6 months of good mud boggin' before

it started making the crunching noises. So, after some emails, off the

diff heads from Jupiter Florida to Chandler Arizona for the autopsy/rebuild.

|

|

|

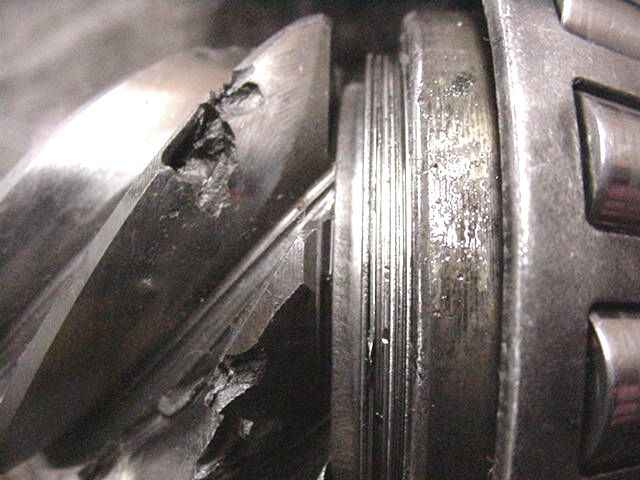

Looks like an alligator took a bite...twice :)

|

|

|

With the 3rd on the bench, the first thing I noticed was the pinion

slop. It's kind of hard to show in this pic but there was about 25 thou of

vertical movement as shown.

|

|

|

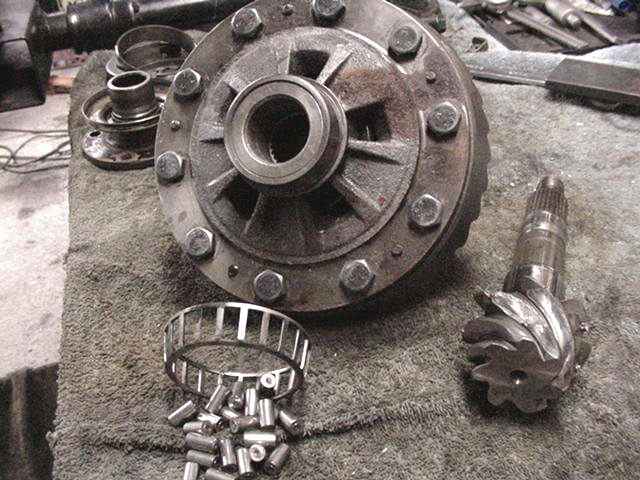

Also, there was no resistance as far as carrier pre-load goes.

|

|

|

The ring teeth are badly hammered.

|

|

|

And it has a low budget GENUINE gear. Here are some of the identifying

marks to recognize a Genuine... TOY-529...

|

|

|

106A4 or alpha-numerics similar to this...

|

|

|

B 9720 or similar....but probably always starting with a B.

|

|

|

Just for the fun of it, I thought I would see how far the wheel would turn

if I rotated it an equal number of notches on both sides...

|

|

|

I was able to get 4 notches from each side without too much trouble. It was very

loose!

|

|

|

The poor pinion was running with so much slop that it had no choice

but chunk off. This same pinion is now welded to my rear bumper on my DD so

it wasn't a total loss. :)

|

|

|

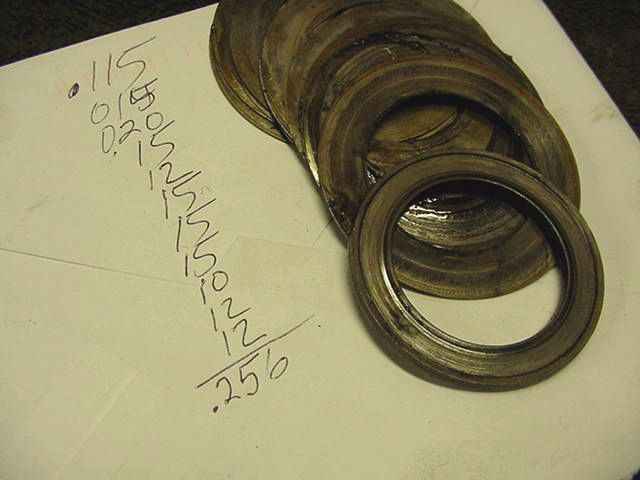

crush sleeves.... :(

|

|

|

Close up of the ugly stack of 11 shims.

|

|

|

After measuring the stack, it looks to be .256" thick. That stack should

not be any deeper than .243" and probably closer to .233"...so between the

pinion being too deep...and the pinion sloppin' around...and loose CBPL...

this ring/pinion was lucky to last the 6 months it did.

|

|

|

The ring gear side carrier bearing fell apart when I removed the case.

Rusty looking Detroit, too.

|

|

|

It actually took some real pulling to get the carrier bearings off. Glad

I had this great puller.

|

|

|

These are good 10.9 metric grade ring gear bolts that are actually among the best

quality I have seen for the Toyota 8 inch. What's really confusing is they come

only in the GENUINE master install kits.

|

|

|

With all the things that were going on in this 3rd, I had to take the

Detroit SoftLocker apart for a damage inspection...

|

|

|

No unusual tooth wear or chips...

|

|

|

...except for the sidegear splines that couple to the axle spline did show significant

wear. Bob might want to check for a bent axle housing.

|

|

|

good teeth...

|

|

|

Remove these from both sides and it becomes an old fashion Hard Locker. I left

them in, of course.

|

|

|

With the Locker back together, now it's time to install the new Yukon

488 gears...starting with the ring gear.

|

|

|

I had a choice....use the brand new somewhat softer bolts...or re-use the 10.9's....

I chose the harder 10.9's. I will clean them on the wire wheel and locktite them.

|

|

|

Ring gear surfaces would see the file as usual.

|

|

|

The ring gear bolts looked like brand new after the wire wheel. Blue Loctite

and 75 ft/lbs.

|

|

|

The new carrier bearings went on very tight.

|

|

|

I'm ready now to put the pinion together...but first, a quick trip to

the local Ace Hardware to get V6 pinion shims...I know alot of you guys

back East don't have nice hardware stores like these but we do out West :)

|

|

|

Nut and bolt isle...there's where I want to go...

|

|

|

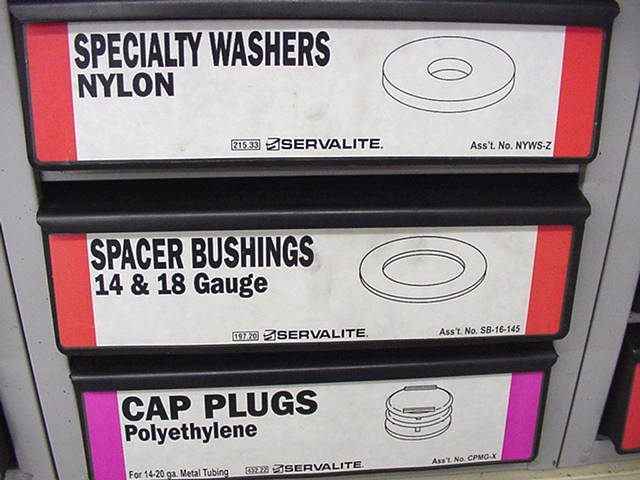

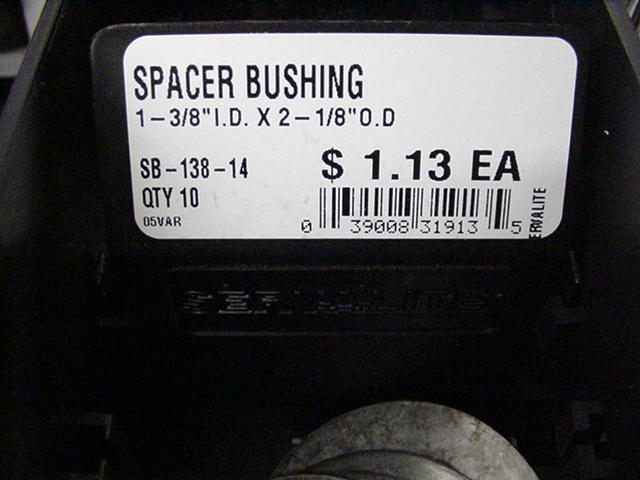

spacer bushings....

|

|

|

only 4 left...better take them all.

|

|

|

|

|

|

10 inch/pounds...

|

|

|

Using a hammer to shock the bearings into equal tension and, with this spanner wrench,

I can place a very effective pre-load that will guard against ring gear deflections.

|

|

|

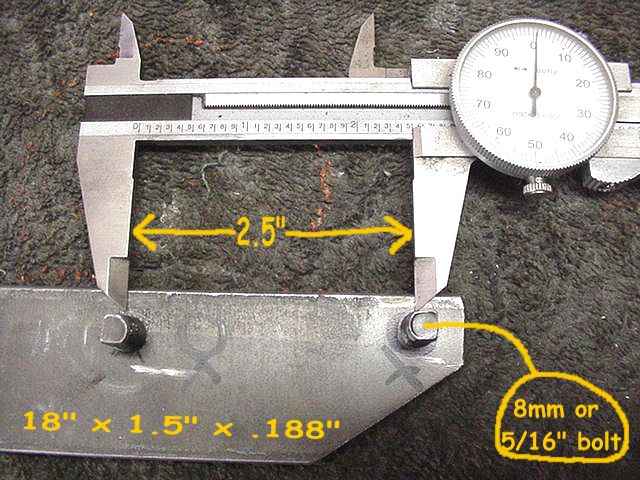

Making your own 'spanner wrench' is quite easy. Get an 18"

piece of 1.5" wide flatstock...about .188" or .250" thick and note the

dimensions in the above picture. 2.5" is a center to center measurement.

|

|

|

The rag/wrench technique really does generate the most distinctive

readable patterns... apply rag here...

|

|

|

turn with 17mm wrench here...back and forth 2 or 3 times...

|

|

|

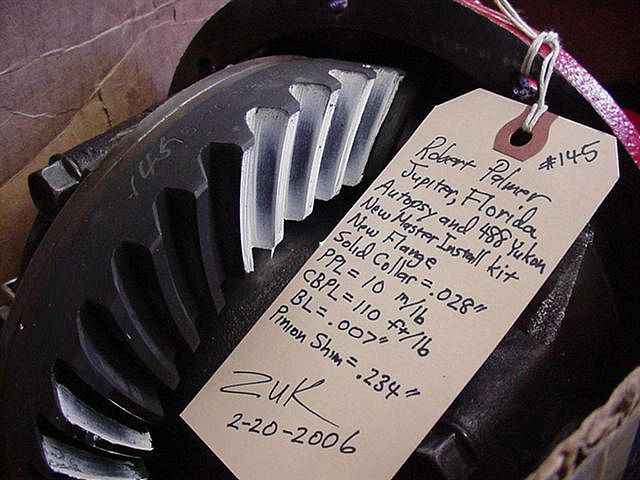

and this is the result. This is proper pinion depth with about 7 thou

for backlash.

|

|

|

Good coast.

|

|

|

I use the torque wrench as more of a check for proper tightness. Even

with gobs of anti-seize on the threads, I saw no movement until I reached 110

ft/lbs. This does not harm the carrier bearings.

|

|

|

The old tabs were beat up and rusted...so I had a brand new pair.

|

|

|

The 4 bearing cap bolts were evenly torqued to 75 ft/lbs. The 2 small tab bolts

had red LocTite applied to clean threads.

|

|

|

A new triple drilled flange was installed. I applied an "adhesion promoter"

followed by a thick coat of bright red.

|

|

|

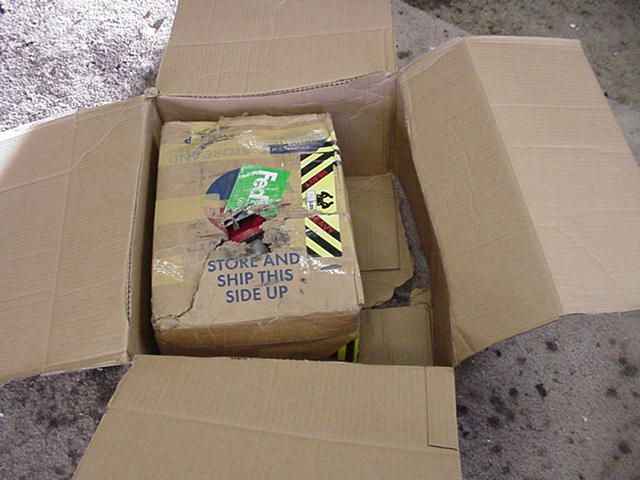

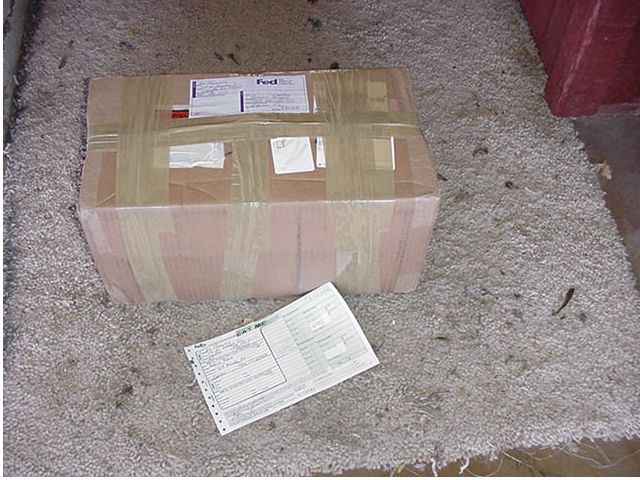

It's not visible but there are 4 box layers in there. These V6 3rds weigh

about 64 pounds so extra cushion is better.

|

|

|

|

|

|

Ready for the trip to Jupiter.

|

|