|

Ben is local to me and upped the size of his tires to 33" on his 2007 Tacoma Pre-runner. He barely had 2300 miles on

the gears but he understood the power of gearing. :) Ben then ordered MOTIVE 4.56 gears to

replace his stock 3.73 ratio.

|

|

|

He also ordered a Taco solid collar and a master kit.

|

|

|

Motive are top shelf gears....made in Italy and sometimes India.

|

|

|

You'd think that with such low mileage that the carrier bearing pre-load would

still be tight. That was not the case here as I could easily detect the looseness.

I know how to keep the CBPL high for a long long time.....2 things...

1- Use thicker shims on both sides to truly add pre-load to the carrier bearings

2- cryogenically treat all 4 bearings. That does amazing things for wear longevity.

|

|

|

I removed the girdle and was able to pull the side shims out by hand indicating that the CBPL was non-existent.

|

|

|

The factory uses a good grade of threadlock and the electric impact had to work a little to get them off.

|

|

|

After filing the mounting surfaces of the new 456 ring gear and applying a liberal amount of red Loctite, the

twelve high quality flange bolts were then tightened to about 90 ft/lb.

|

|

|

Most of the factory pinion pre-load PPL was gone. I measured about 1 in/lb of remaining drag.

|

|

|

Beating the pinion out with a hammer is not the way to do it even though the only thing that is being re-used is the flange.

|

|

|

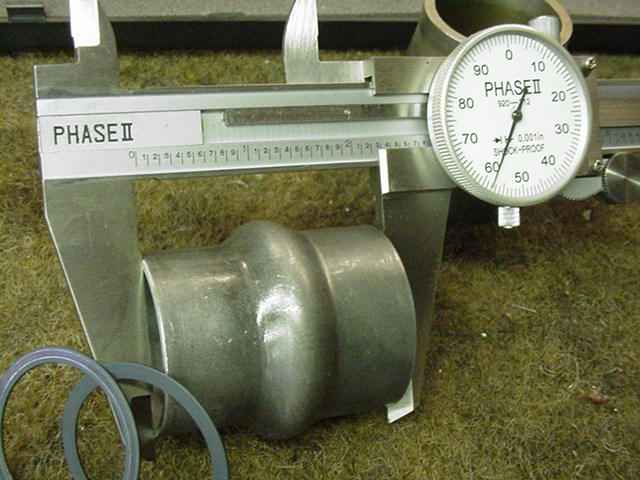

I can save time and effort if I measure the length of the old crush sleeve and the 2 "spacers" that the factory

assembles it with. Then use that data to determine what shim to use on the solid collar. I got lucky and .052"

for the first try was 'on the money' with a measured PPL of 12 in/lb.

|

|

|

The pinion depth shim is pressed on behind the large inner race so the inner bearing shown

here will have no shim. Then the solid collar is slipped on with the .052" shim for PPL.

|

|

|

The 30 spline flange was a very tight fit onto the 30 spline pinion....so tight that I decided to carefully

press it on and off twice to help free it up a little. But it was still tight even after that.

|

|

|

I wish the older Toyota trucks would fit that tight. :)

|

|

|

The new carrier bearings were pressed on at the same time. My press sees alot of use during a typical

gear install ;)

|

|

|

The original shim on the left (case side shim) measured .112" thick....the one on the right (ring side shim) measured .113.

For what it's worth, when all was said and done, the one on the right stayed .113 but the left grew to .129.... That means

I added 17 thou to the overall pre-load/tightness compared to the original factory set-up.

|

|

|

I document all of the shim changes I do. It helps to have a good selection of genuine

Taco pinion depth shims. The dealer is the only place that has them. They can cost up to $7 each.

|

|

|

I re-used the factory 083 shim. Depth appears excellent.

|

|

|

Coast side looks equally nice.

|

|

|

Even the pattern on the pinion itself shows the depth as being nicely centered in depth.

|

|

|

With the girdle and the case out, I could install the pinion seal now and really crank on the

pinion nut with the 4-foot bar. I used red Loctite, of course, and truly did put some weight behind the bar. It stayed

at 12 inch pounds of pinion drag. God help the guy that has to loosen this pinion nut. :)

|

|

|

Last chance to fine tune the BL and the CBPL by adding thicker shims....

|

|

|

The 4 carrier bearing bolts were tightened to about 80 ft/lb.

|

|

|

One more pattern check and all is good.

|

|

|

...

|

|

|

I date coded this install with a sense of pride...it's interesting to see that Motive sometimes uses

dimple marks to code their gears.

|

|

|

...

|

|

|

Done. Ready for Ben to pick up :)

|

|