|

As received from Ben, the partially assembled rear 9" E-Locker. These things are HEAVY DUTY and....HEAVY!

They weigh about 80 pounds.

By the way, from what I've learned, these are actually spec'd at 8.875" diameter. But when I measure from outer most part of

the radial pitch line, I measure 9.500" less a few thousandths.

|

|

|

The ring gear teeth are impressively large.

|

|

|

12 special bolts and nuts hold the ring gear on. This is a quality Motive gear.

|

|

|

......

|

|

|

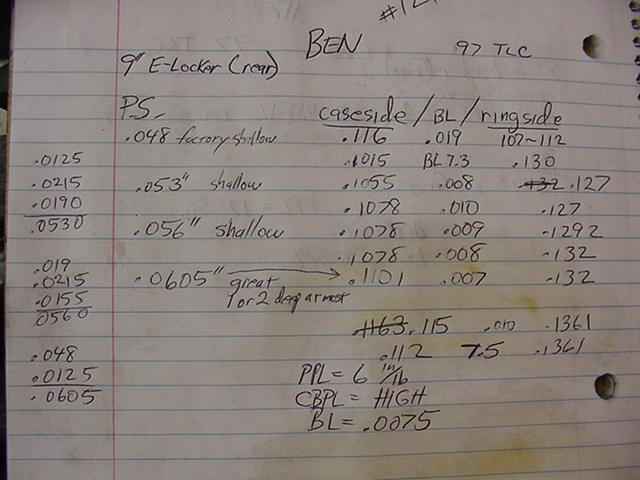

The factory shim measured to be .048".

|

|

|

Pressing the shim and bearing on with the 10 ton.

|

|

|

Just making sure that the bearing splitter will be able to grab the bearing well enough to remove it.

Looks like it can.

|

|

|

Looks like I can even flip the splitter over if I choose to and can take it off this way, too.

|

|

|

I have assembled the pinion without the crush and will carefully tighten the pinion nut with the electric impact until

the used bearings reach about 5 inch/pounds of pre-load. Extreme caution as the nut approaches tight.....but the nature

of the electric impact makes this very controllable.

|

|

|

Using a pendulum style torque wrench, I check for about 3~6 inch/pounds of rolling drag.

|

|

|

Backlash is set in the ballpark....

|

|

|

The ring gear specifies .008 for BL so that is the final desired value no matter what the FSM says.

|

|

|

...

|

|

|

too shallow

|

|

|

...

|

|

|

Deep on the pinion means shallow on the ring gear as shown above.

|

|

|

Now to tear it down to try a thicker pinion shim. Push the pinion out...

|

|

|

...remove the bearing...

|

|

|

...new shim goes on and the bearing is pressed back on...

|

|

|

Better....but still shallow

|

|

|

...

|

|

|

The pinion still looks a little deep meaning a little shallow on the ring.

|

|

|

These are shims that I normally use for the T100 Taco solid collars and they work perfect

for this 9" E-Locker pinion shim. Adding 3 thou for a total of .056"....

|

|

|

...still a touch shallow.

|

|

|

...

|

|

|

The pinion pattern agrees with that.

|

|

|

Bullseye has again slept thru an entire gear install.

|

|

|

Finally, after adding another 4.5 thou to the pack, I see that the ring gear pattern is maybe 1 or 2 thou

on the deep side. This is a highly desirable condition in terms of best overall gear strength. Theoretically,

gear noise increases but none will be heard here. It would be heard if it were 15 or 20 thou over the ideal.

|

|

|

Funny how the drive looks slightly deep while the coast here looks perfect.

|

|

|

The pinion is in the ideal region.

|

|

|

Now, one more time tearing it down to add in the crush sleeve. The rear 9" EL has no solid spacer option yet.

|

|

|

Seal is "prepped" and ready to tap on.

|

|

|

My seal installer is simple....an old V6 bearing race and a beat up pinion flange.

|

|

|

The FSM recommends grease but I choose to use red Loctite. It offers some degree of

lubrication...it just seems like a better method to me....especially when I know the larger 30mm pinion

nut can tolerate it. The same is not true of the older mini-truck/Runner's smaller 7.5" IFS front carriers(86~95 models) that use the

smaller 24mm pinion nut...I use anti-seize on those(an excellent lubricant).

|

|

|

Tightening the pinion nut is much easier with a plate bolted to the tabletop that captures the pinion

flange and a long breaker bar of sorts.

|

|

|

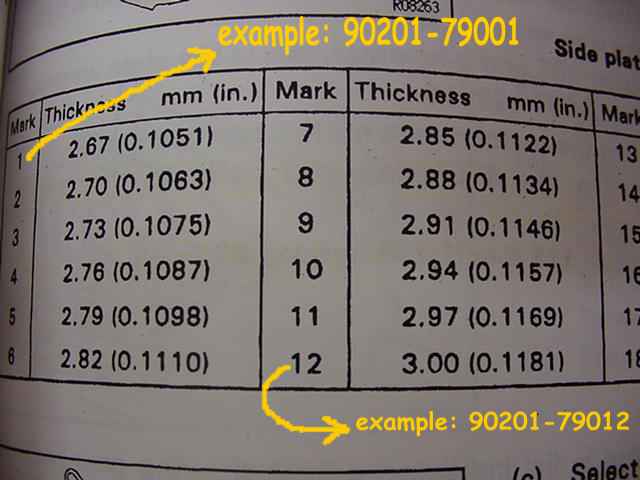

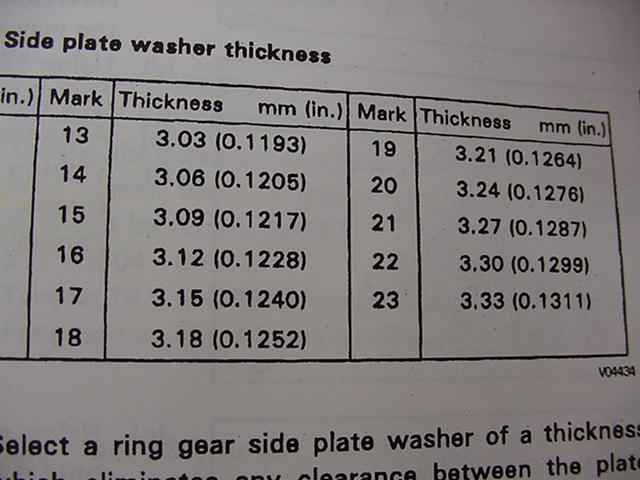

These are the part numbers for the 23 different possible carrier bearing shims/plates that set the BL and CBPL.

|

|

|

...

|

|

|

Using 2 shims like I have shown on the right side (one thick and one thin at about .010" thick)

does not work. The thin ones gets destroyed trying to pound in the thick shim next to it. I had

to remove the carrier bearing and place 15 thou behind it. I had some very good CBPL

(carrier bearing pre-load)...enough to deform the stout thick round shim some because it was such a tight squeeze.

|

|

|

FSM (Factory service manual) says 81 ft/lb and that's what I use.

|

|

|

The specs I use are scribed on the ring gear...

|

|

|

...and date coded.

|

|

|

You must keep notes of the shims used....otherwise you will go crazy trying to remember what you

used the last go-around. Done :) ZUK

|

|