|

|

|

|

|

|

||

Billy is another local and felt his 92 pick-up with the 3.0 liter engine and factory 488's was a bit sluggish with the new 33x10.50 tires. After some discussion, Billy decided on the upgraded "preformance series" of Genuine Gear in the 571 ratio and a Truetrac with a master kit. The IFS 7.5" front will remain open and that install link is located at the end of this long page. |

||

|

||

``` |

||

|

||

These PERFORMANCE SERIES gears get the thumbs up

|

||

|

||

``` |

||

|

||

``` |

||

|

||

Parts are unpacked and organized. |

||

|

||

Markings found on this 571 8" ring. |

||

|

||

``` |

||

|

||

2 small dimples keep me from mixing up the bearing caps. An additional note- the above 3rd is a standard V6 3rd (carrier) that I had to dig up for this gear install. After-market gears do not work in the unique rear V6 factory 3rds that have the factory 488 ratio in them. Due to the extra thin factory 488 ring the pinion hole was moved about .25" inwards/closer to the ring. Even if the carrier bearings could be shimmed .25" over there are still other clearance issues with the case to carrier itself. |

||

|

||

Teardown begins....the electric impact takes some of the work out of it. |

||

|

||

The carrier is cleaned with starter fluid. New races are waiting. |

||

|

||

The 12 ton press effortlessly coaxes the races in. |

||

|

||

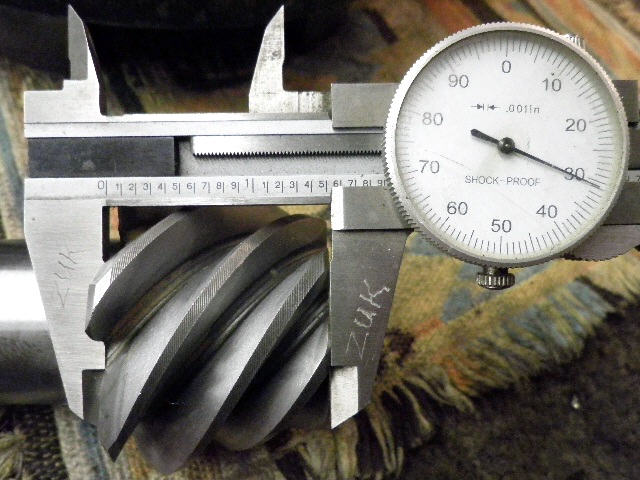

Just making sure this is a short pinion head... 1.530 means short and 1.666"(approx) means long pinion head(V6 models). |

||

|

||

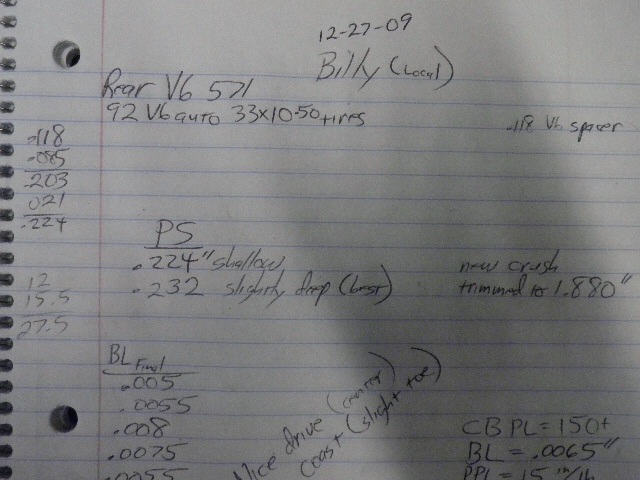

No strength differences between the short and long pinion heads...it just means a thicker pinion shim will be used to make the "4 cyl" gears work in a "V6" carrier. In this case, I will start with a .224" shim. |

||

|

||

Press the pinion bearing on... |

||

|

||

...assemble the top end with no crush sleeve. Lots of gear oil on both bearings for an accurate measurement. Tighten the pinion nut until about 15 inch-pounds of pre-load is measured. |

||

|

||

Onto the other end...surfaces were filed and no high spots or burrs detected. |

||

|

||

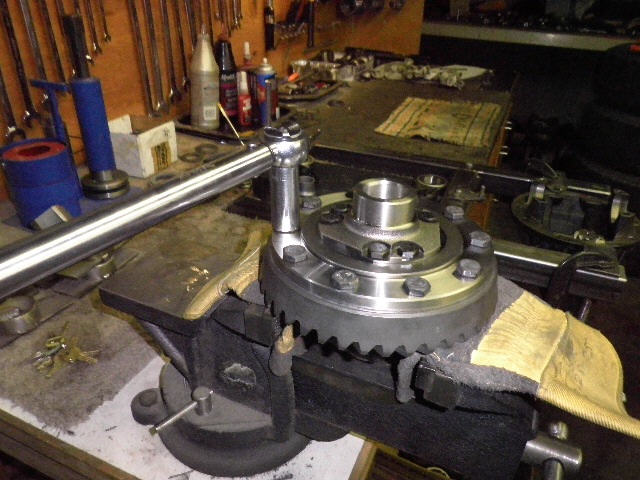

The ring slipped onto the Truetrac rather nicely this time. It went on by hand...but not a sloppy fit by any means. The higher quality 10.9 bolts have red loctite applied. |

||

|

||

75 ft/lbs to all 10 bolts in a criss-cross pattern. |

||

|

||

Both carrier bearings are pressed on at the same time. I noted that they were a very tight fit also. |

||

|

||

The Truetrac is set in place and the bearing caps are tightened down. I always make sure the carrier bearings have some decent pre-load for the upcoming pattern check. The backlash is set to about .007"... |

||

|

||

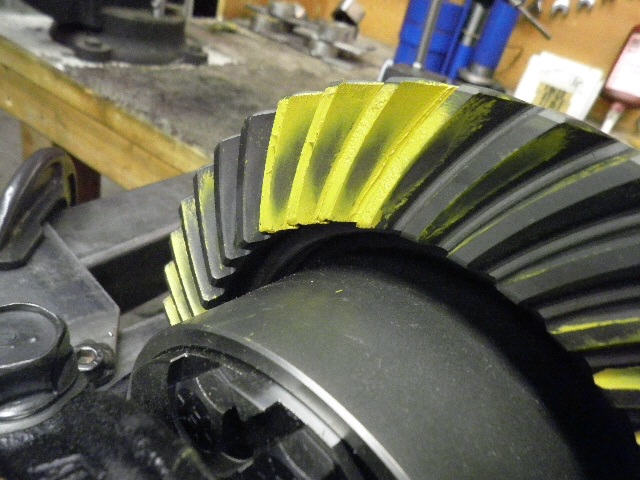

...and the paint is applied. With the fixture that I have for supporting this 3rd, it's an easy matter of lightly applying resistance to the pinion flange and turn the ring gear back and forth 3 times with a 17mm wrench. The resultant pattern is easy to read and says to me....very close...but perhaps a touch shallow? Just a tad on the heel.... |

||

|

||

...the coast side is a less dependable read...slight toe and maybe top of tooth(shallow) |

||

|

||

When a drive and coast pattern of the ring-gear reads like that, I get a 3rd pinion. This one has deep contact. Deep in the pinion means shallow on the ring. |

||

|

||

Teardown time....press the pinion out... |

||

|

||

...use the extra large bearing separator to easily remove the typically tight V6 bearing... |

||

|

||

I want the pinion to push deeper into the ring so a thicker .232" shim is employed. I'm only adding .008" to the overall thickness but that can make quite a difference...it might even end up too deep. |

||

|

||

Got lucky....beautiful. It's a keeper. This shows the depth to be right in the bullseye zone. |

||

|

||

Coast looks sweet also. |

||

|

||

The pinion looks nice now. I see the shift in the load bearing closer to the outside now. |

||

|

||

One last teardown. This time, the new crush sleeve is slid over the pinion. |

||

|

||

The new seal has grease on the inside and rtv on the outside. The grease keeps the spring from popping off and the rtv acts as a sealant and also helps the seal to tap in place easier. |

||

|

||

Some light gear oil is also applied to the lips of the seal and then the flange can be installed. |

||

|

||

Loctite is probably not mandatory...but it sure seems like good insurance to me. |

||

|

||

With the pinion flange rigidly secured, the 3 foot cheater bar can easily crush the sleeve. |

||

|

||

Crush a little then measure, crush then measure. After about 8 times, the pinion pre-load measured in on a target 15 inch/pounds. |

||

|

||

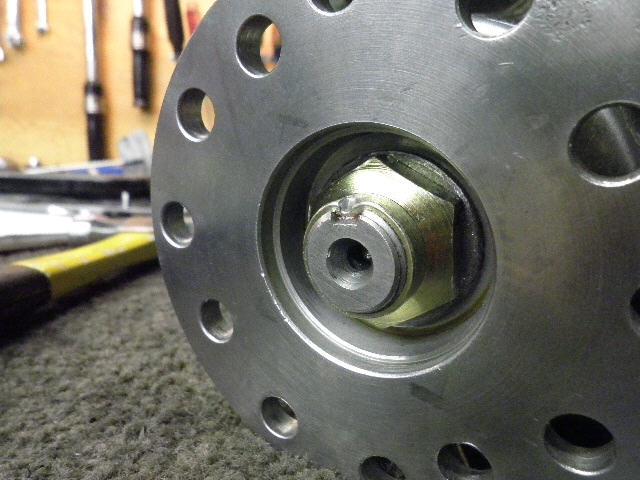

Ding the nut and this end is done. |

||

|

||

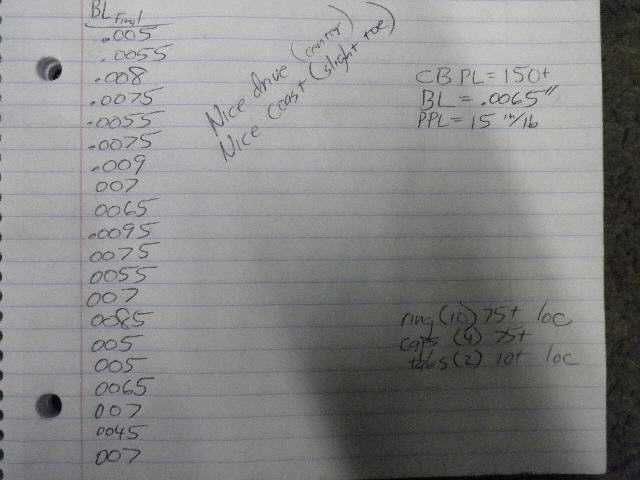

The Truetrac can now be installed. Backlash and CBPL carrier bearing pre-load are the final 2 ingredients in this performance cocktail. |

||

|

||

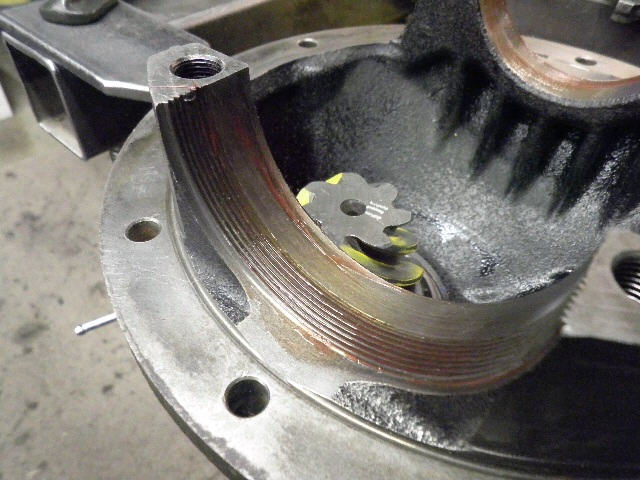

I used to use aluminum anti-seize on the threads but the red grease seems to do the job also. It reduces thread resistance. |

||

|

||

If the caps have been properly installed then the cap bolts can be fully tightened to 70~75 ft/lbs. |

||

|

||

Backlash and CBPL are dialed in. Then I usually do a verification that the wheels truly are tight. 150 ft/lb on the torque wrench and the wheel still won't yield. This translates into about 15 inch/pounds of actual carrier bearing drag as determined by tests I did a couple of years ago. |

||

|

||

Last final check....nice. |

||

|

||

good. |

||

|

||

... |

||

|

||

Notes taken during Billy's install... |

||

|

||

``` |

||

|

||

Billy sent a couple picks...here's the rear 571 3rd that he has just re-installed... |

||

|

||

|

||

|

from me.

from me.