| Harold's 2018 Tacoma TRD 8.75" rear 3rd gets Nitro 529 gears |

|---|

| (82 BIG pics loading) |

|---|

| June 30 2019 |

|---|

|

| Harold's actual 2018 Taco TRD as shot right at the Camelback dealership. |

|---|

|

|

Color: Inferno Orange.

3.5L 24 valve DOHC, 6 speed automatic transmission.

Overdrive is a fantastic .58

Has 33" tires as shown right now but will soon see 35" |

|---|

|

|

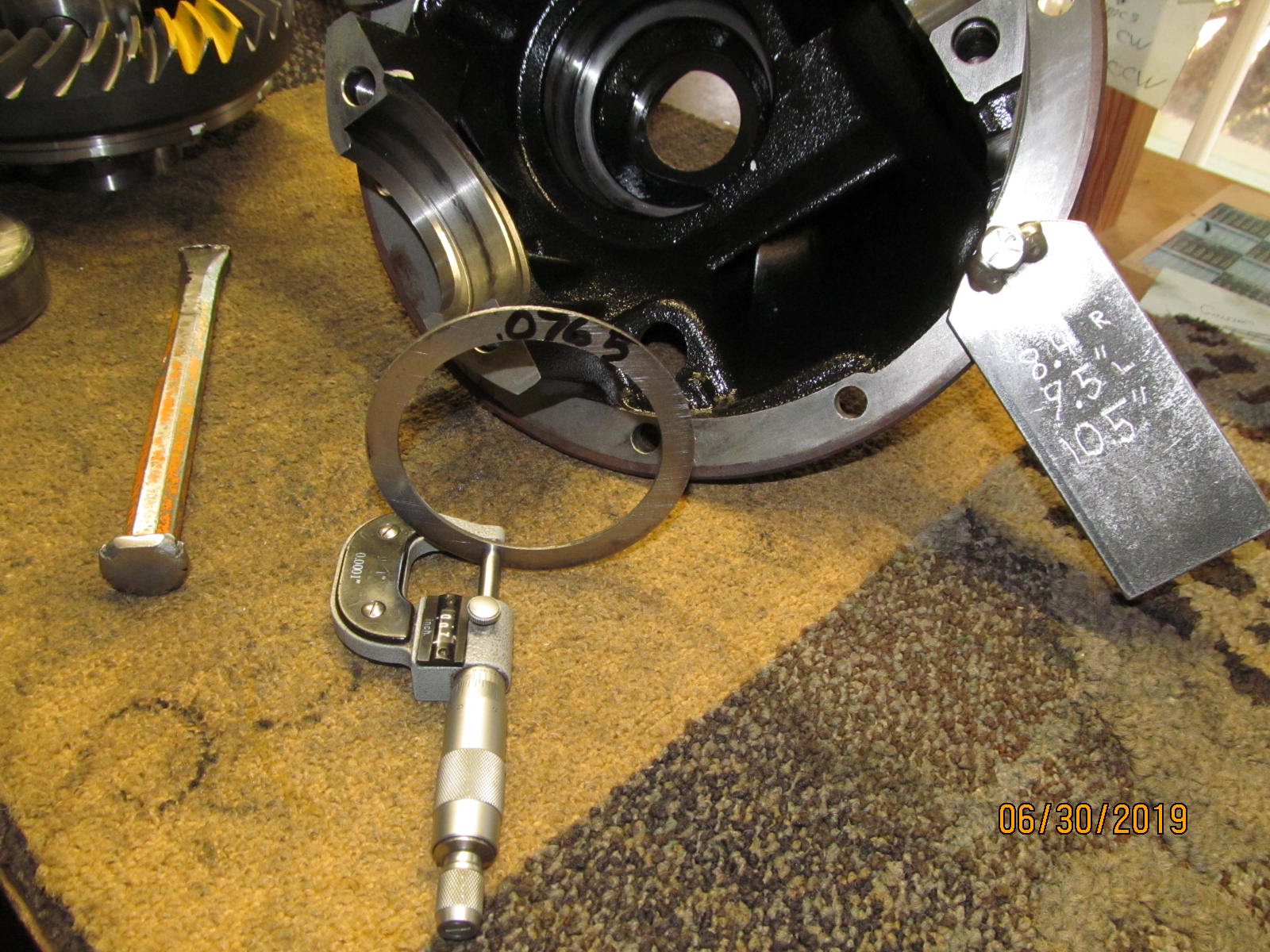

Harold's 8.75 rear e-locker 3rd is on the bench with the stock 3.91 gears.

Nitro 529 gears and a genuine pinion seal shown....but no bearings.

On a 2018 or 2019 Tacoma, it can be argued that the bearings are already still like brand new. |

|---|

|

|

| Nitro 529 gears and a genuine Toyota pinion seal. The pinion shaft is massive. |

|---|

|

|

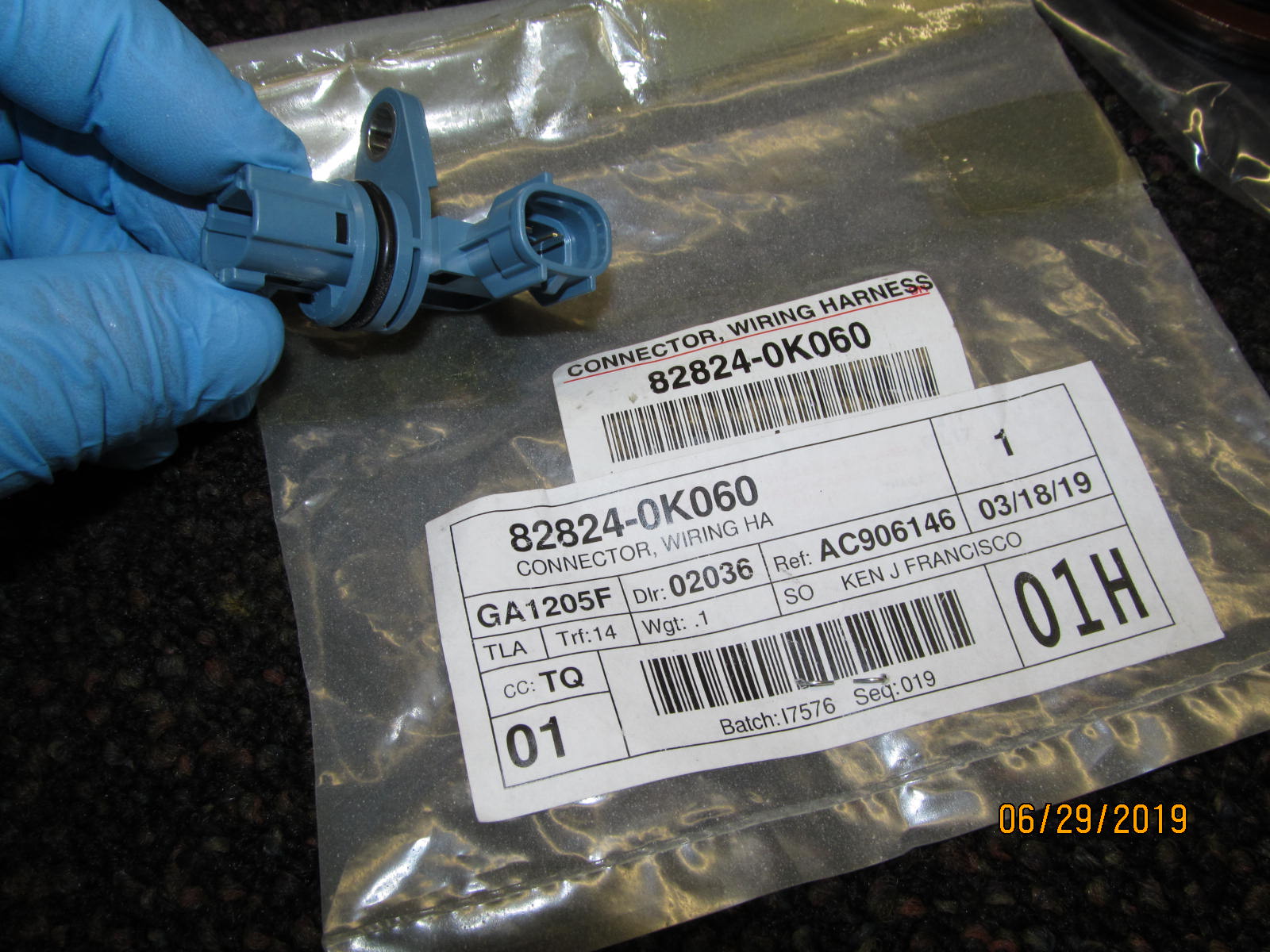

The only other thing that might also be replaced is the blue connector (elocker connector).

I keep a few always in stock. |

|---|

|

|

| ============================== |

|---|

|

|

Go to the dealer and the black connector on the left will run $100......

The blue one is about 35. |

|---|

|

|

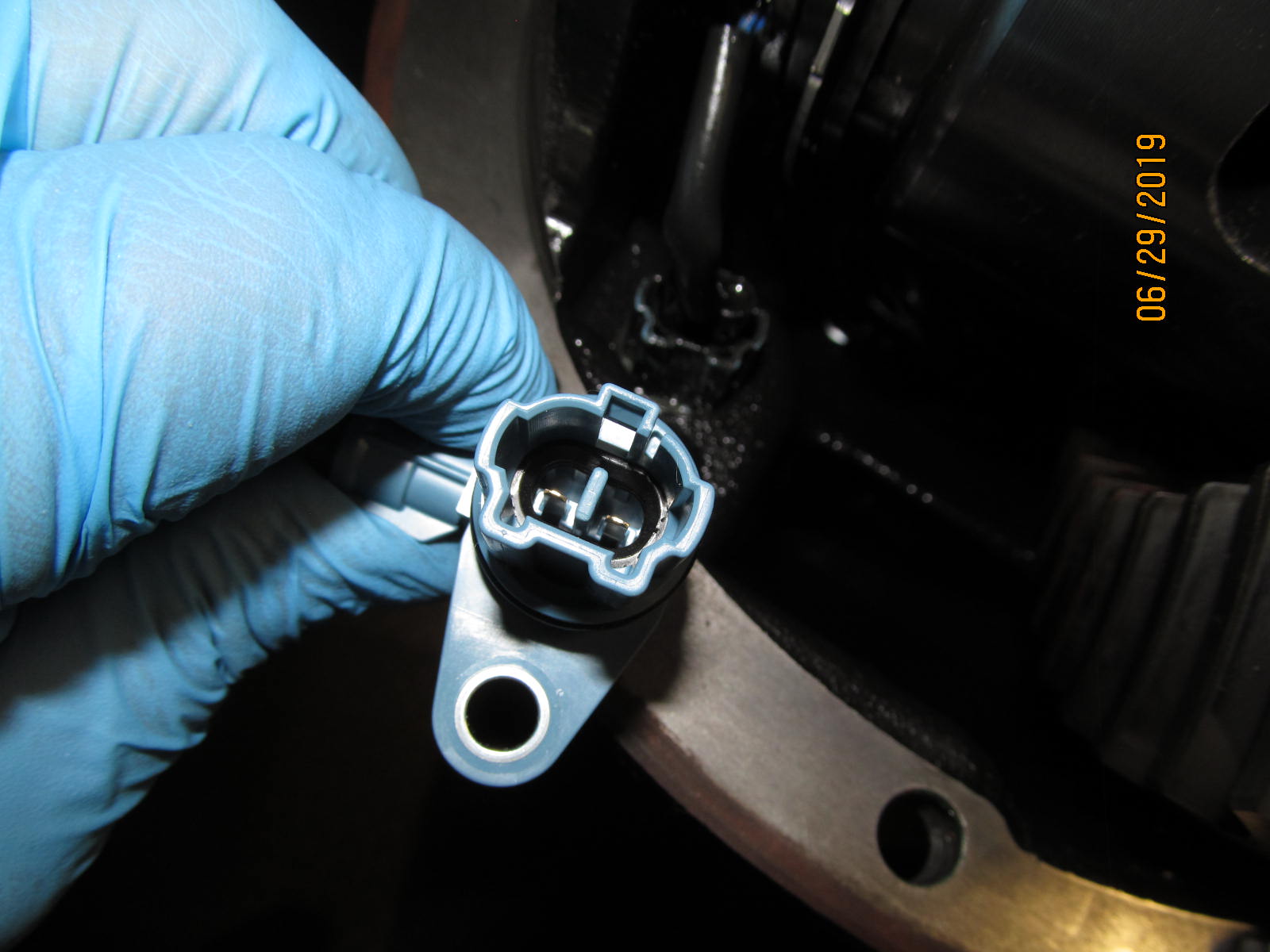

That connector really is blue. I suspect this is the original gear oil from 17,000 miles ago.

Harold will be using Valvoline Full Synthetic 75W-90.

Synthetics can be left in much longer, they will lubricate better, they will run cooler,

and they will not leave blackish coatings on the internals. |

|---|

|

|

| This is the new connector that I suspect I will be using. |

|---|

|

|

Sure enough, could not get this plug out without breaking the delicate tab off the other half.

It's in there so tight that , even though this is a 2018 model, the connector was being stubborn

and the other half had to be destroyed.

And that's exactly why I keep a few "blues" on hand. |

|---|

|

|

| Even with the tab broken off, the plug would not pull out so "operation destroy" proved to be very effective. |

|---|

|

|

| The new blue connector shown plugged in 60% of the way. |

|---|

|

|

| With the minimal $35 cost, it's just not worth the fight to save the old connector. |

|---|

|

|

No destruction is needed for removal of this one.

The differential case should be removed first then the black connector can easily be removed. |

|---|

|

|

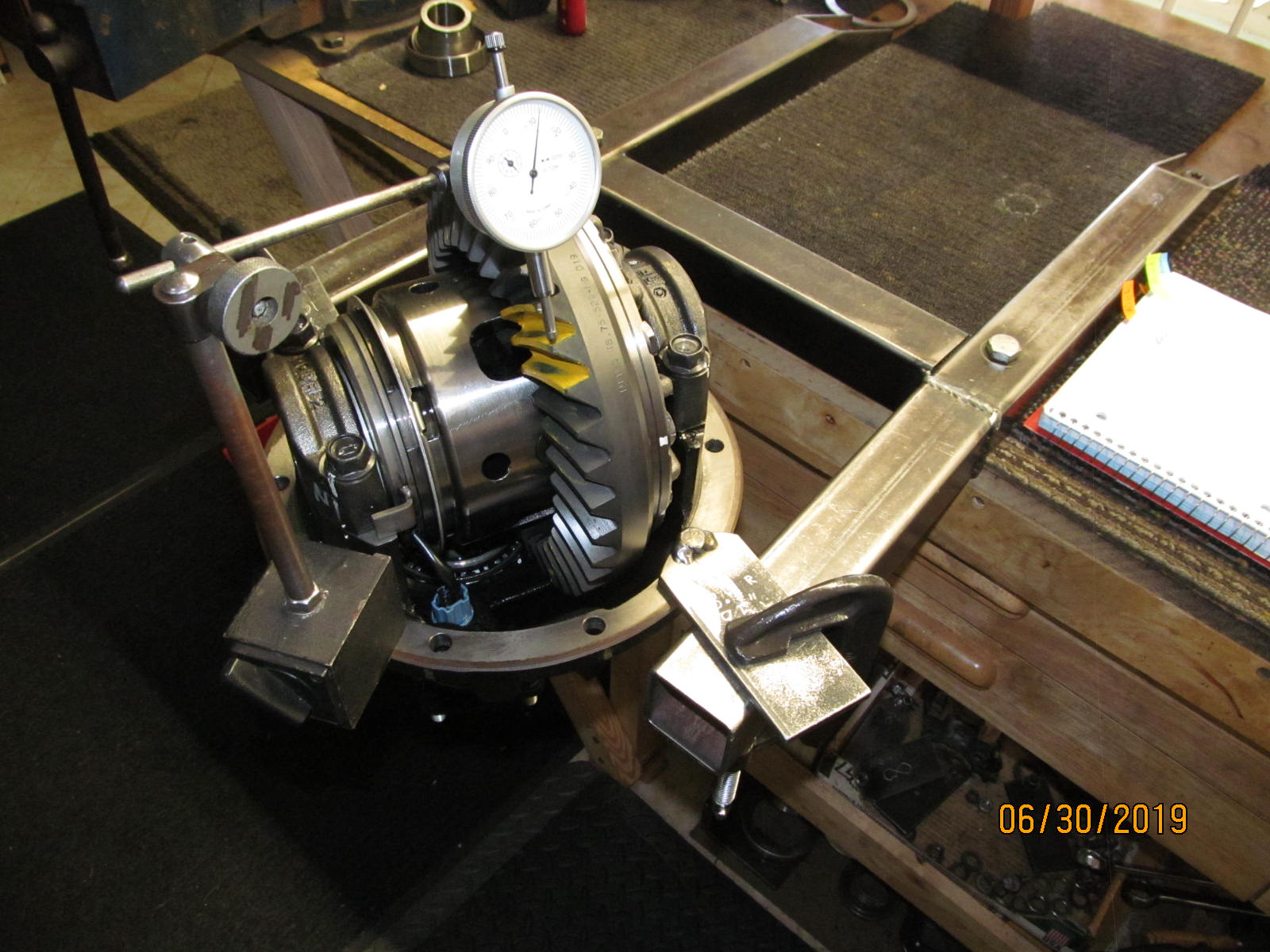

| But first, a quick check of the total preloads.....looks like about 10 inch/pounds. |

|---|

|

|

Differential case in the process of being removed.

The 2 bearings caps are removed first. |

|---|

|

|

The washer plates were almost loose enough to remove by finger power.

When I'm done with it later, it will be much tighter. |

|---|

|

|

| ding ding ding and out it comes. |

|---|

|

|

| Carrier bearings in nice shape.....as they should be with a low 17k miles on them. |

|---|

|

|

| Other side in fine shape too. |

|---|

|

|

| Now, let's get this thing out of the way. |

|---|

|

|

| Remove the 6mm bolt with a 10mm wrench..... |

|---|

|

|

| Out it comes. |

|---|

|

|

| Getting the pinion out.....the cordless impact wrench has plenty of torque for this. |

|---|

|

|

| ..................................... |

|---|

|

|

| Pushing the pinion out.....probably less than 1 ton of actual push is needed. |

|---|

|

|

| Pre-cleaned the flange....and you can see that it's almost like new with the tiniest of grooves. |

|---|

|

|

| OEM is hard to beat. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| Outer bearing in beautiful shape. |

|---|

|

|

| The big inner bearing is excellent. |

|---|

|

|

| ############################### |

|---|

|

|

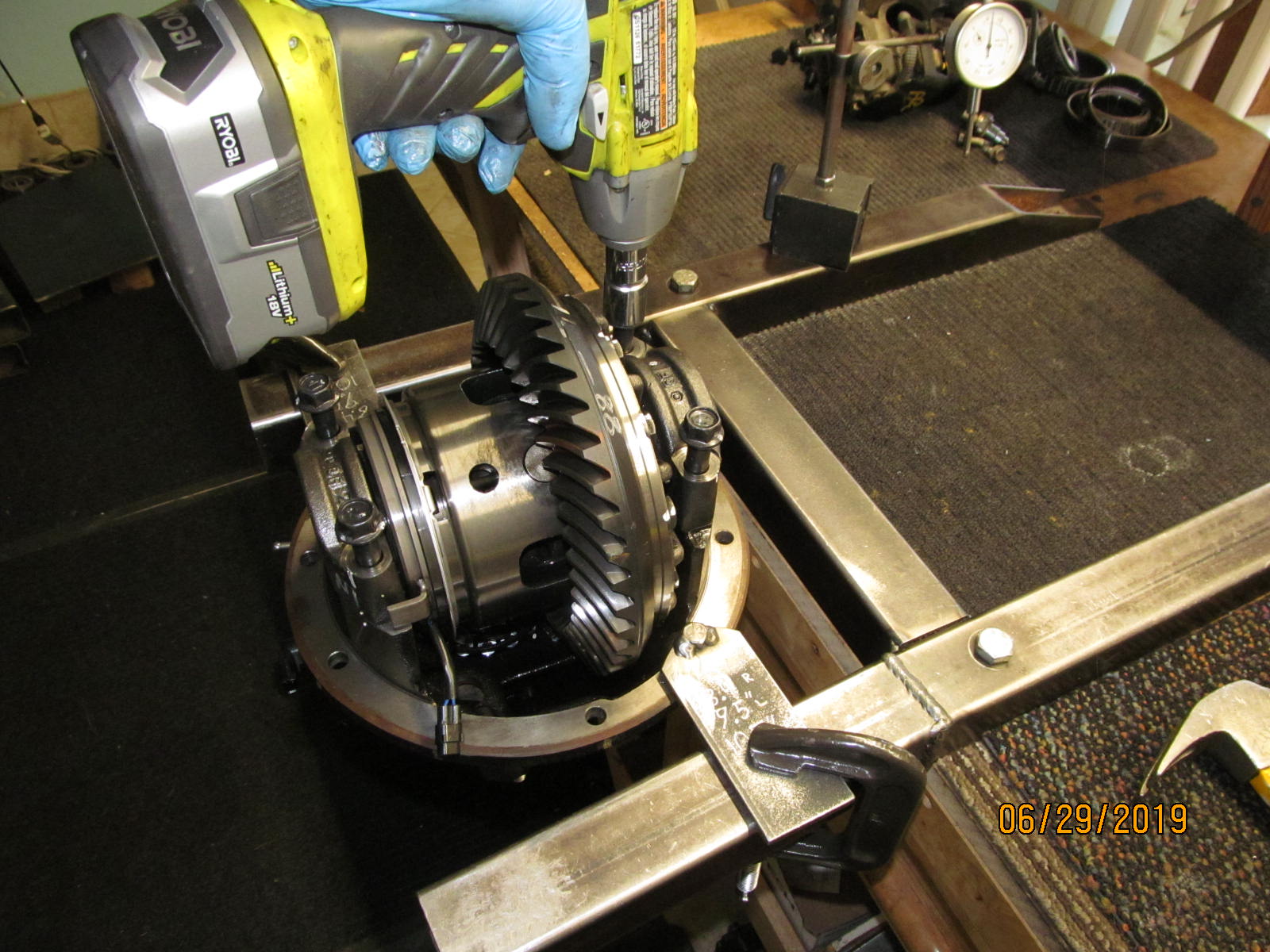

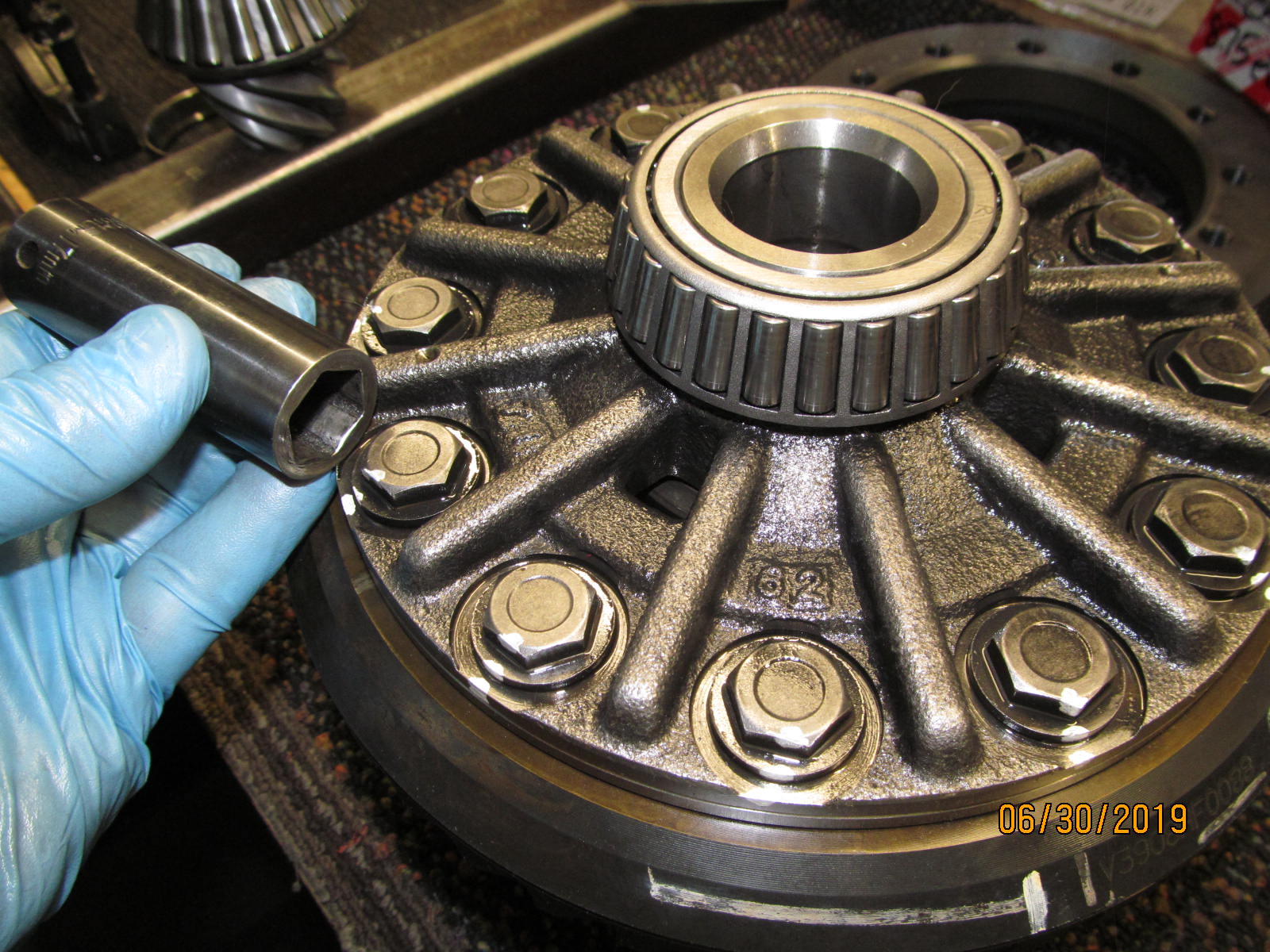

| Now to remove the 12 ring gear bolts. |

|---|

|

|

With a fresh battery, the cordless took all 12 bolts off.

The factory used a good red loctite on the threads. |

|---|

|

|

| High speed bench wire wheel cleaned the debri off the bolts just fine. Starter fluid removed all the oils. |

|---|

|

|

| "old" 3.91 ring knocked out. |

|---|

|

|

| Nitro 529 ring ready to go on. |

|---|

|

|

| The Nitro ring tapped on very snug. |

|---|

|

|

| 92 ft/lb with red Loctite. |

|---|

|

|

| The big pinion bearing was swapped over to the Nitro 529 pinion. |

|---|

|

|

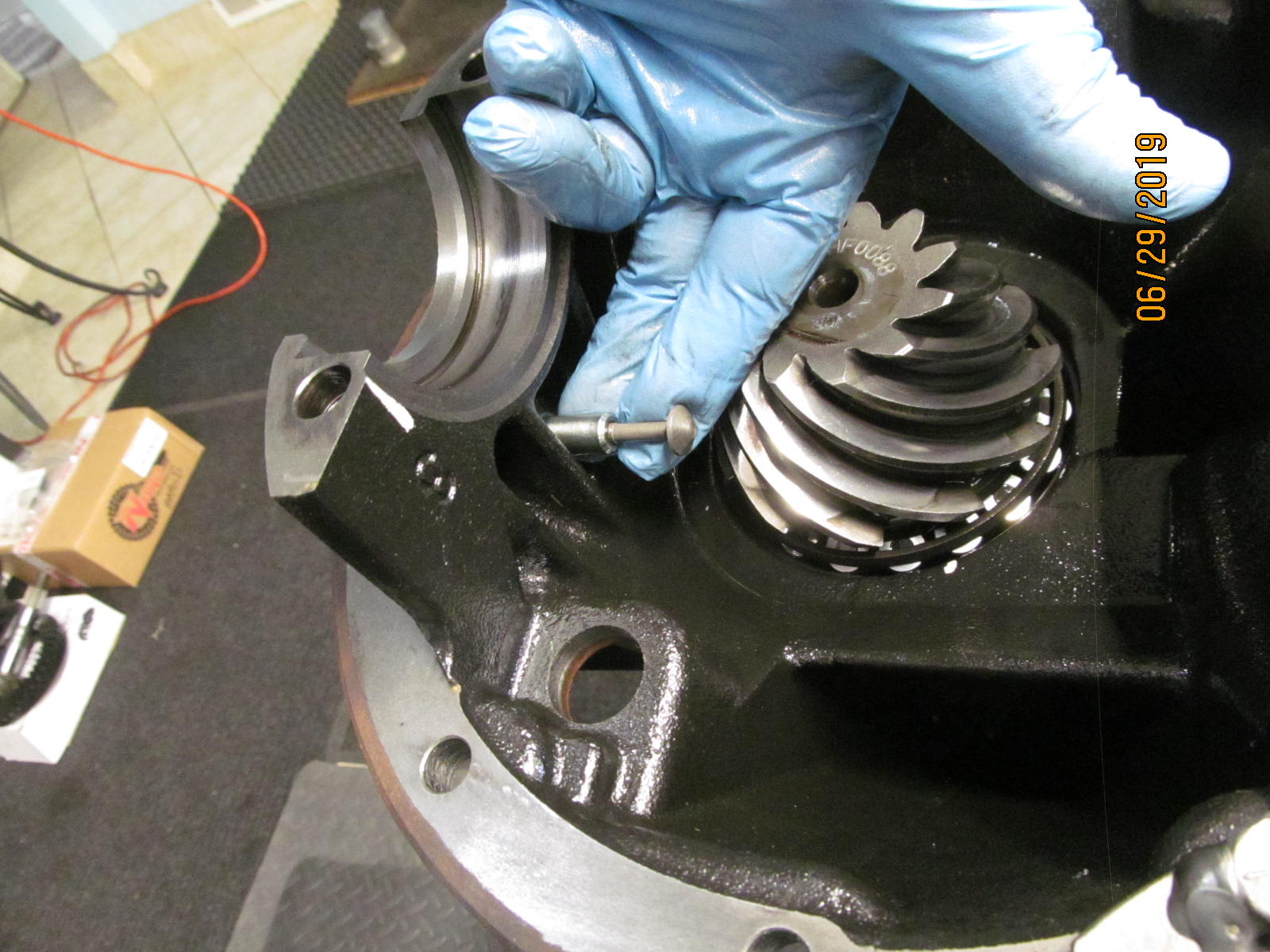

| Pinion is mounted in diff carrier and only tightened enough to offer some pinion preload...... |

|---|

|

|

| .....roughly about 9 inch/pounds worth. |

|---|

|

|

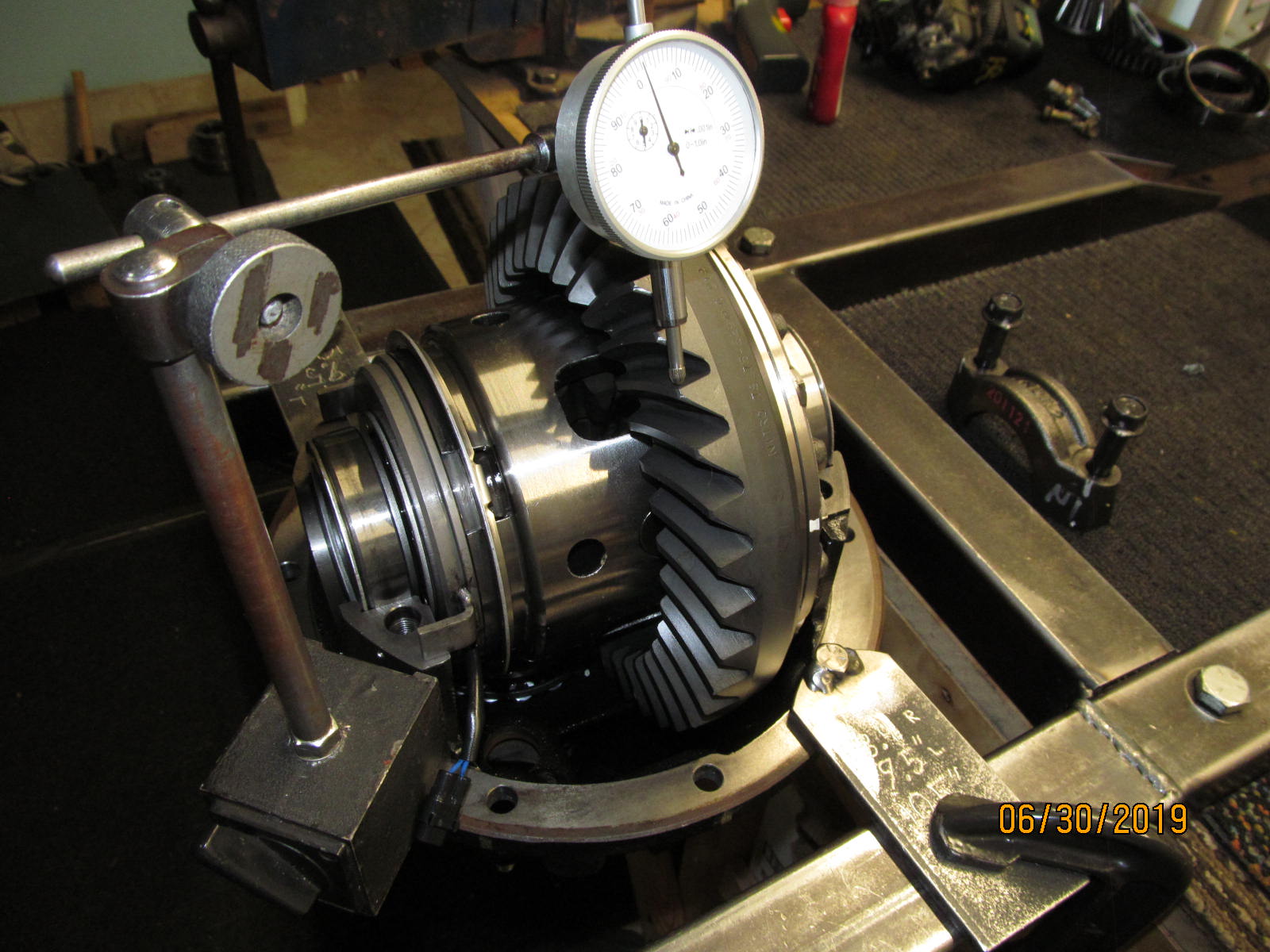

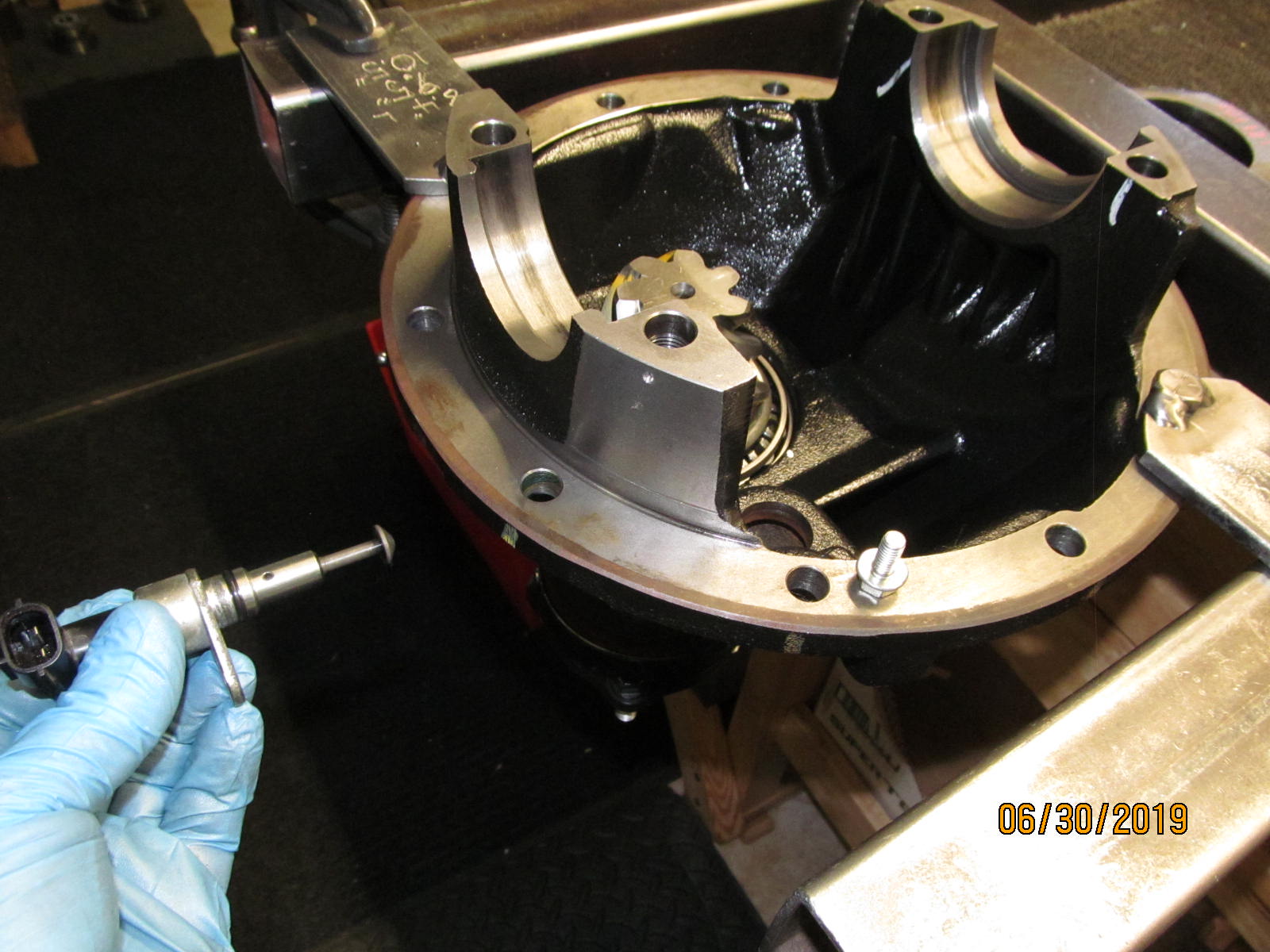

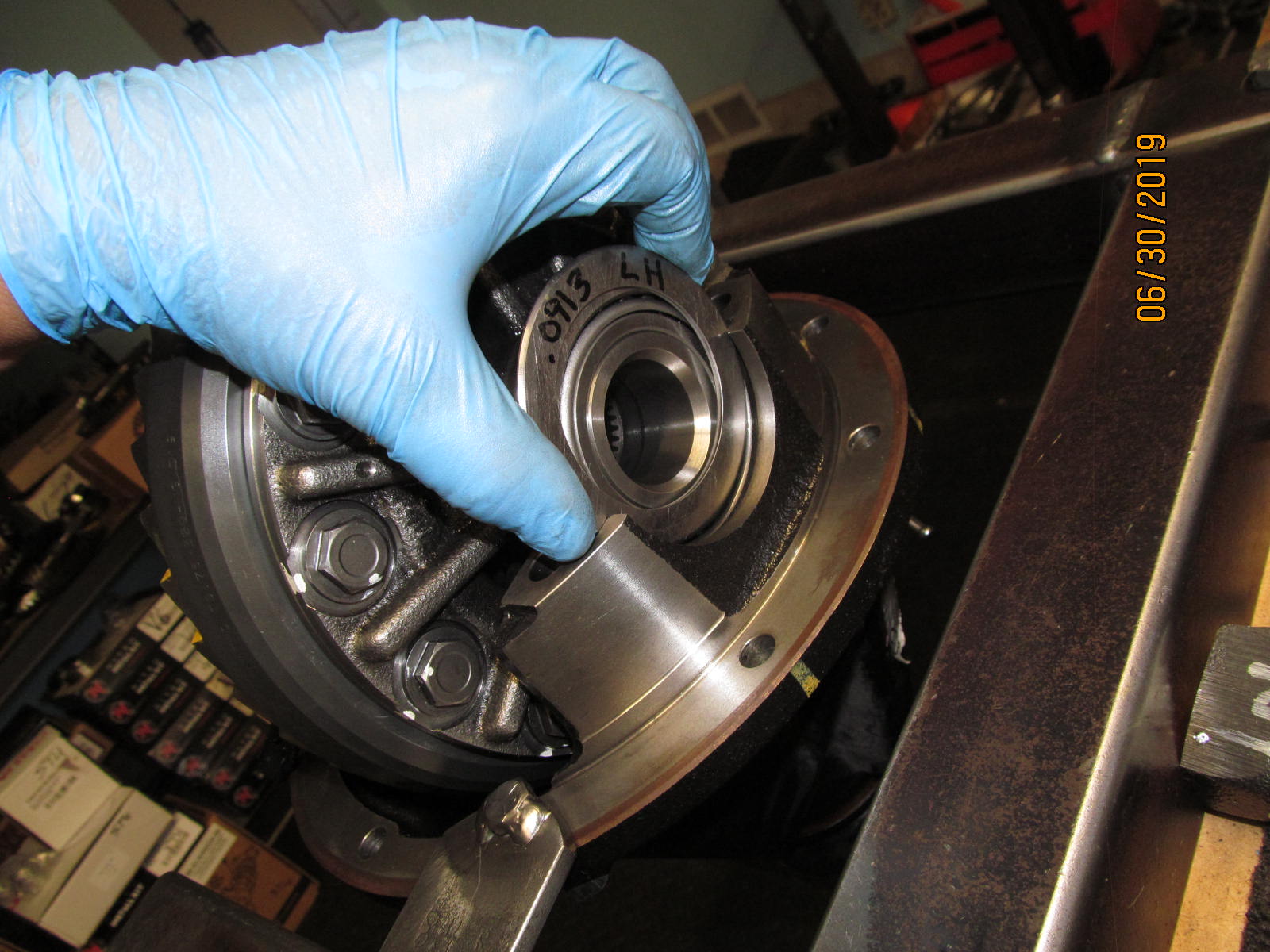

| Differential case is re-installed with the factory washer plates. Backlash was measuring close to zero. |

|---|

|

|

| Did some mental math and changed out the washer plates. |

|---|

|

|

| Perfecto......now was measuring .0055" at the tightest places. |

|---|

|

|

| 1st paint test....DRIVESIDE.....looks shallow. |

|---|

|

|

| COAST......shallow. |

|---|

|

|

| Comet tail.....hugging the root too much so that says shallow for the ring gear. |

|---|

|

|

| ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; |

|---|

|

|

| Now to push the pinion out again to add some more shim to the pinion. |

|---|

|

|

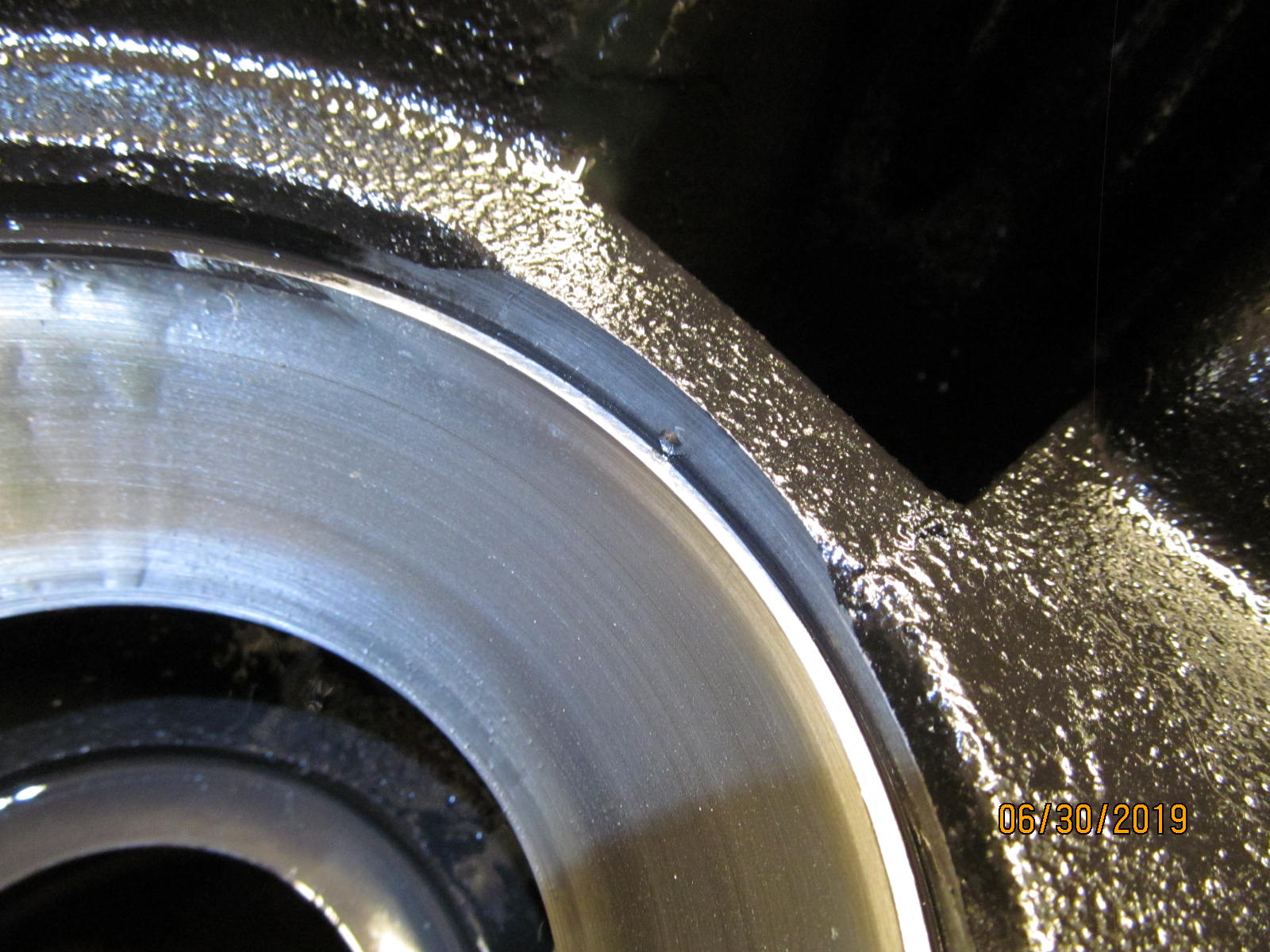

| Inner big race. Marked it so I can keep the orientation in the exact same spot. |

|---|

|

|

| The pinion shim is located behind the inner race. |

|---|

|

|

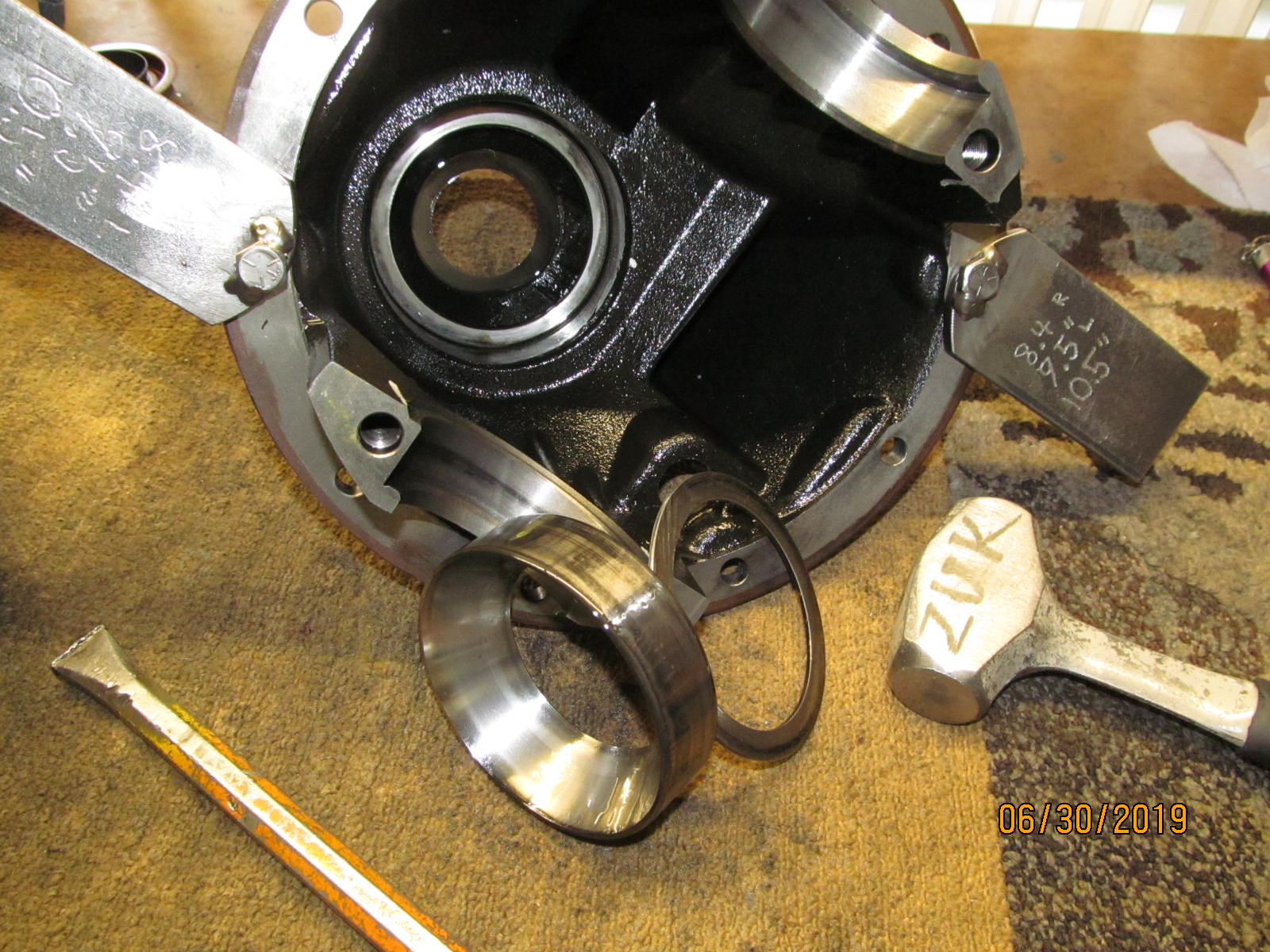

| The factory shim thickness measured at .0765" roughly. |

|---|

|

|

| Removing the inner pinion bearing with the 12 ton Harborfreight press. |

|---|

|

|

| Going to relocate the shim to the pinion head. There are certain advantages to doing that. |

|---|

|

|

| .083" is .0065" thicker than the factory .0765" shim. |

|---|

|

|

| Skipped a few steps...pressed bearing on pinion and tightened pinion nut enough to offer some preload. |

|---|

|

|

| DRIVE....Much better. Looks "slight deep" which is my favorite condition. |

|---|

|

|

| COAST....looks wonderful. |

|---|

|

|

| The comet tail no longer deep in the root....almost out to center. |

|---|

|

|

| The tail says to leave it alone. |

|---|

|

|

| The factory crush sleeve has thicker sidewalls then the aftermarket ones. It's a bit more stout. |

|---|

|

|

Because we no longer have a thick .0765" shim behind the race means that the old crush sleeve is now too long.

Too long by about .076" so I shaved off .050" and still have plenty of sleeve to crush. |

|---|

|

|

| I have noticed that the factory sleeves fit the pinion shaft "better" and do not wobble around nearly as much. |

|---|

|

|

| Testing the fit of the new oem seal. We already know it fits great but this is habit. |

|---|

|

|

| Lining it up. |

|---|

|

|

| Tapping it down smoothly and evenly. |

|---|

|

|

| Apply gear oil to all the contact areas of the flange. |

|---|

|

|

Not shown but there is anti-seize on the pinion threads and the bottom of the nut.

It makes crushing the thick sleeve possible with this cordless impact. |

|---|

|

|

Even with new gear oil splashed liberally on the bearings there was still a little stickiness in the readings

but seemed to be around 7 or 8 inch/pounds. |

|---|

|

|

| DING!! and this end is done. |

|---|

|

|

| Nice and smooth. |

|---|

|

|

| Good time to put the lock sensor in now. |

|---|

|

|

| A dab of petroleum jelly lubes up the o-ring. |

|---|

|

|

| Then the differential case is loaded......then the carrier bearing washer plates. |

|---|

|

|

A little thicker washer plate on this side adds a little extra backlash and preload.

Fortunately, these are high quality washer plates and can take some good hits.

The 2 bearing caps are mounted and torqued to 84+ ft/lb on the 4 bolts. |

|---|

|

|

| Kinda going back and forth but now is a good time to apply medium strength Loctite and 6 ft/lb to both connectors. |

|---|

|

|

| The black plug pushed right in all the way and heard the retaining tab lock it in place. |

|---|

|

|

| Backlash checked and recorded on every other tooth. |

|---|

|

|

| Date coded...... |

|---|

|

|

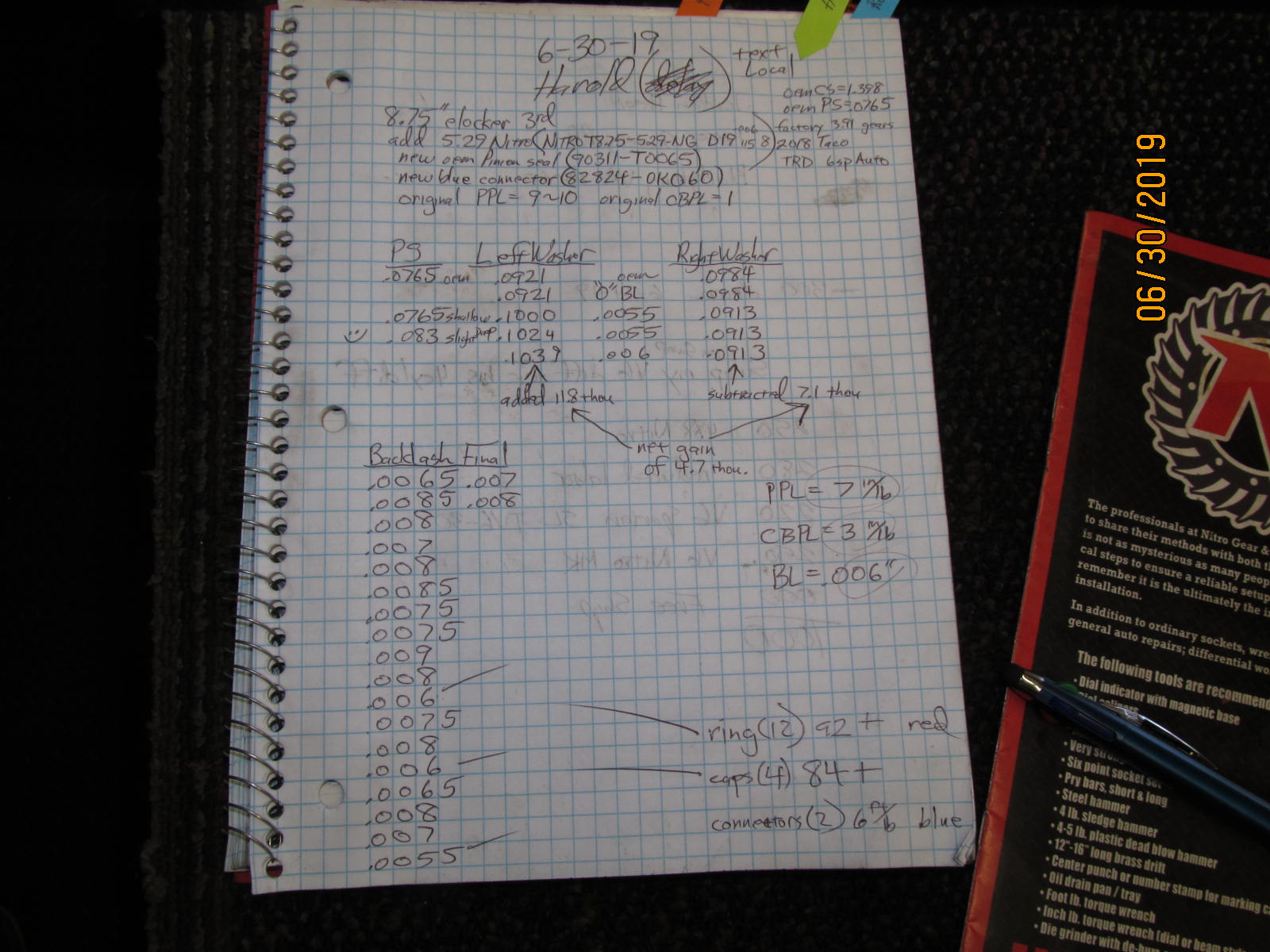

| A snapshot of the assembly notes. |

|---|

|

|

|