|

Jacob's 01 4Runner has a very loud whine from the rear 8" diff with ARB and Nitro 529 Gears

|

|

(59 BIG pics loading)

|

|

DEC 6 2016

|

|

|

Jacob is out of Austin TX and, as can be seen, has a very nice 01 Runner. SAS front end

using a D44 out of a Bronco. Radius arms for now but the future might hold a

3 link. 37/12.50/17 KO2's with Racelines.

|

|

|

|

The rear V6 8" 3rd already has Nitro 529 gears with an ARB air locker in it. But recently, started

getting a very loud whine. He could not find anyone locally that would fix it and then Jacob

remembered the guy on the internet that he has been following up on for over 10 years so

off he sends the 3rd to me.

|

|

|

|

|

A couple days later this arrives.

|

|

|

|

|

The burlap bags offered a good cushion but had a weird warehouse smell to them.

|

|

|

|

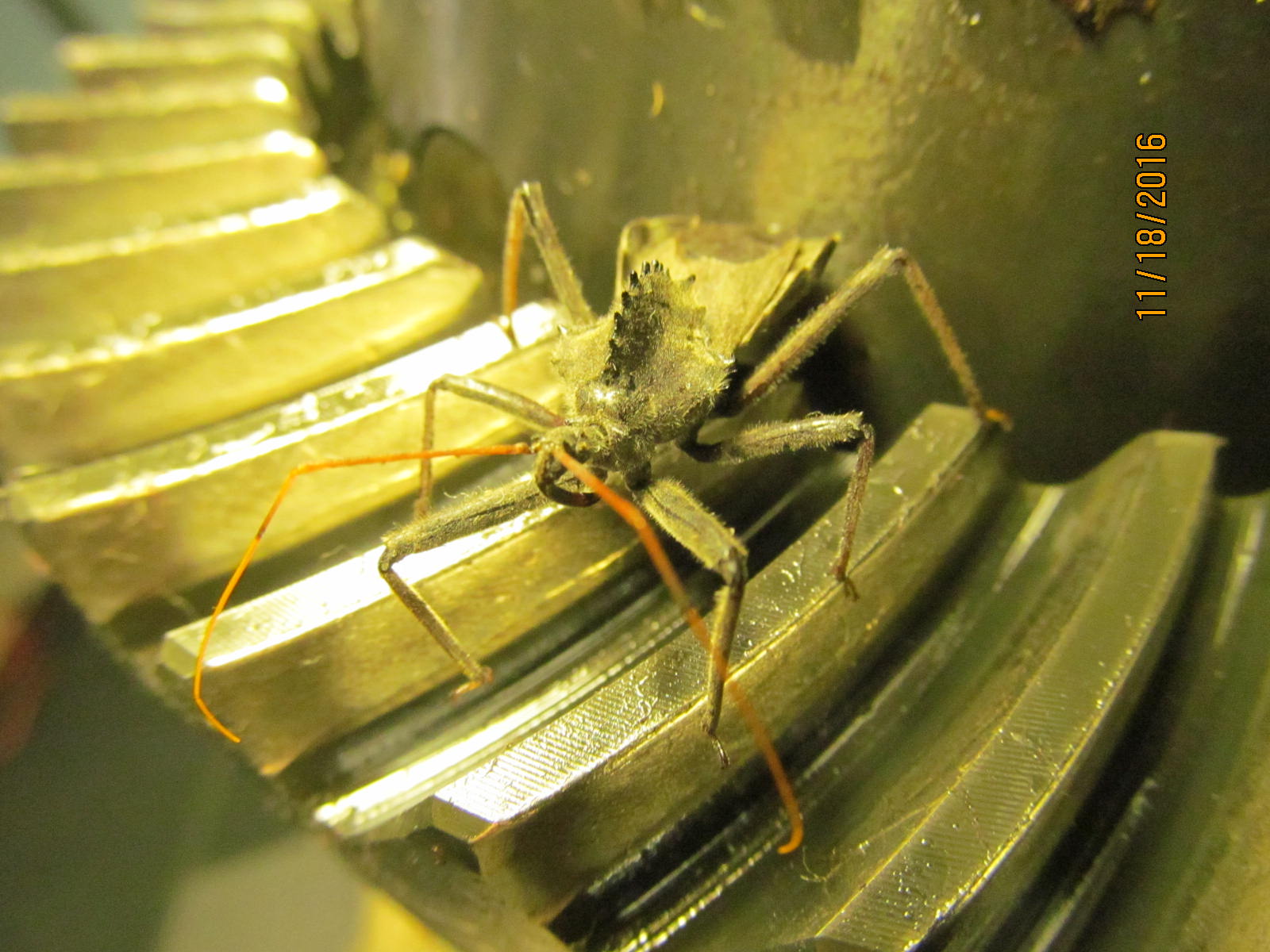

I took the 3rd out, placed it on the bench, and went to move the boxes out of the way.

When I turned my attention back to the 3rd this little guy was watching me. Sorry

buddy, but I can't properly diagnose Jacob's diff with you hanging out in my livingroom.

|

|

|

|

|

Texas has some weird beetles....must have been in one of the burlap bags.

Known as a wheel bug.

|

|

|

|

|

He was a full sized one. He ended up in my backyard.

|

|

|

|

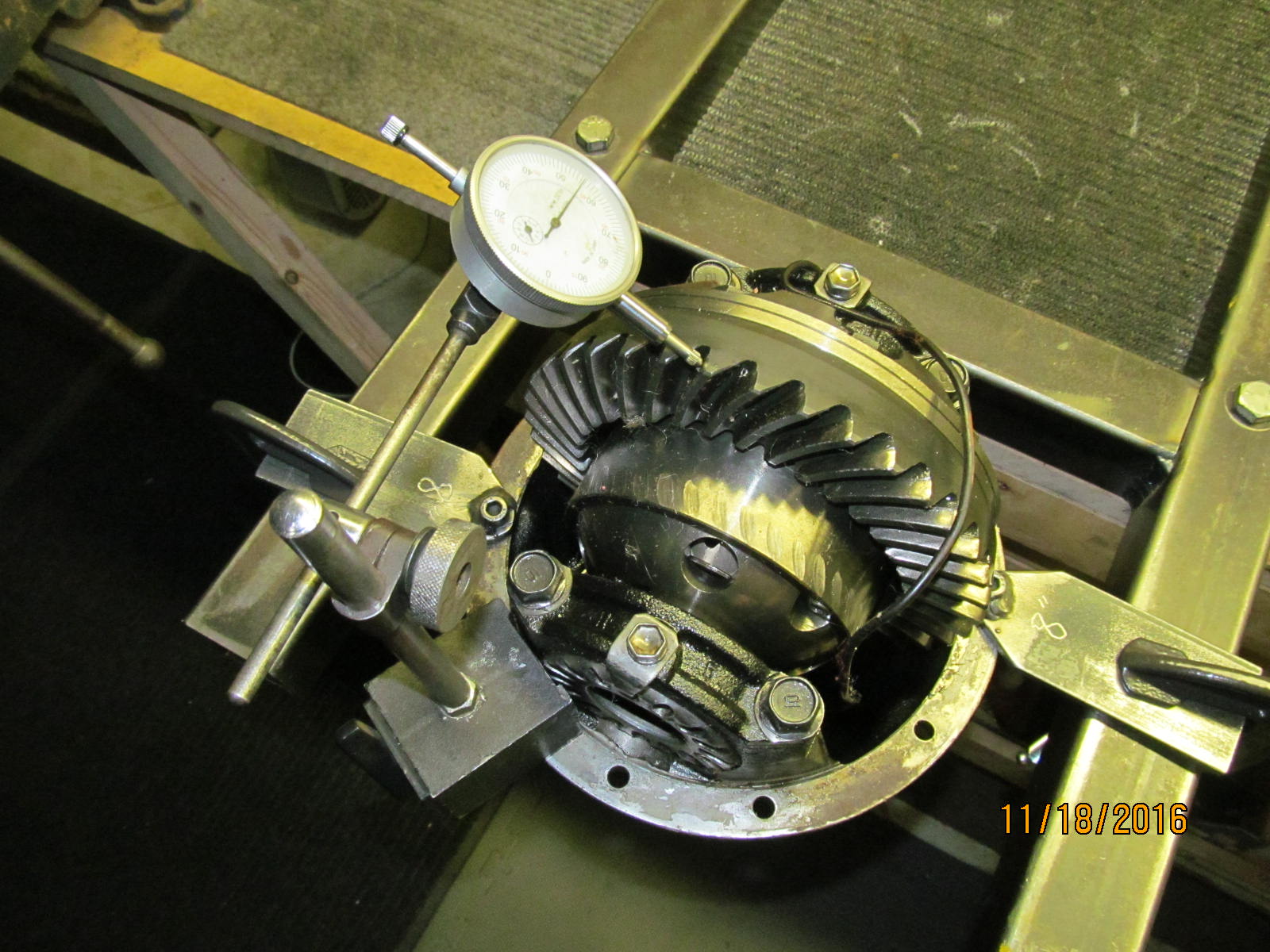

Now onto the business of the autopsy....backlash was so excessively large and measured at .050"

which is about 6 times too large.

|

|

|

|

You can see the pinion swirl marks in the ARB case so either sometime in the past a different ring and

pinion set caused this cosmetic damage or the carrier bearings, being loose to the point of visual wobble

in the ARB case, shifted enough to contact the edges of the pinion teeth.

|

|

|

|

|

The ring gear teeth were hammered to death.

|

|

|

|

|

Too bad because this was a high quality Nitro Gear at one time.

|

|

|

|

I noted that before I loosened the bearing caps that the ARB case wobbled around....the carrier

bearings were unbelievably loose, in other words. I think the wheel adjusters slipped a thread over.

That can happen when the installer does not properly mesh the threads in the first place.

|

|

|

|

|

With the case and the bearings slamming around this is the result.

|

|

|

|

|

Not surprisingly, the carrier races are equally as bad.

|

|

|

|

This pinion was properly clearanced it looks like. See how the edges are chamferred? Looks like it was

done with a flapper wheel which is the preferred tool for this type of job.

|

|

|

|

|

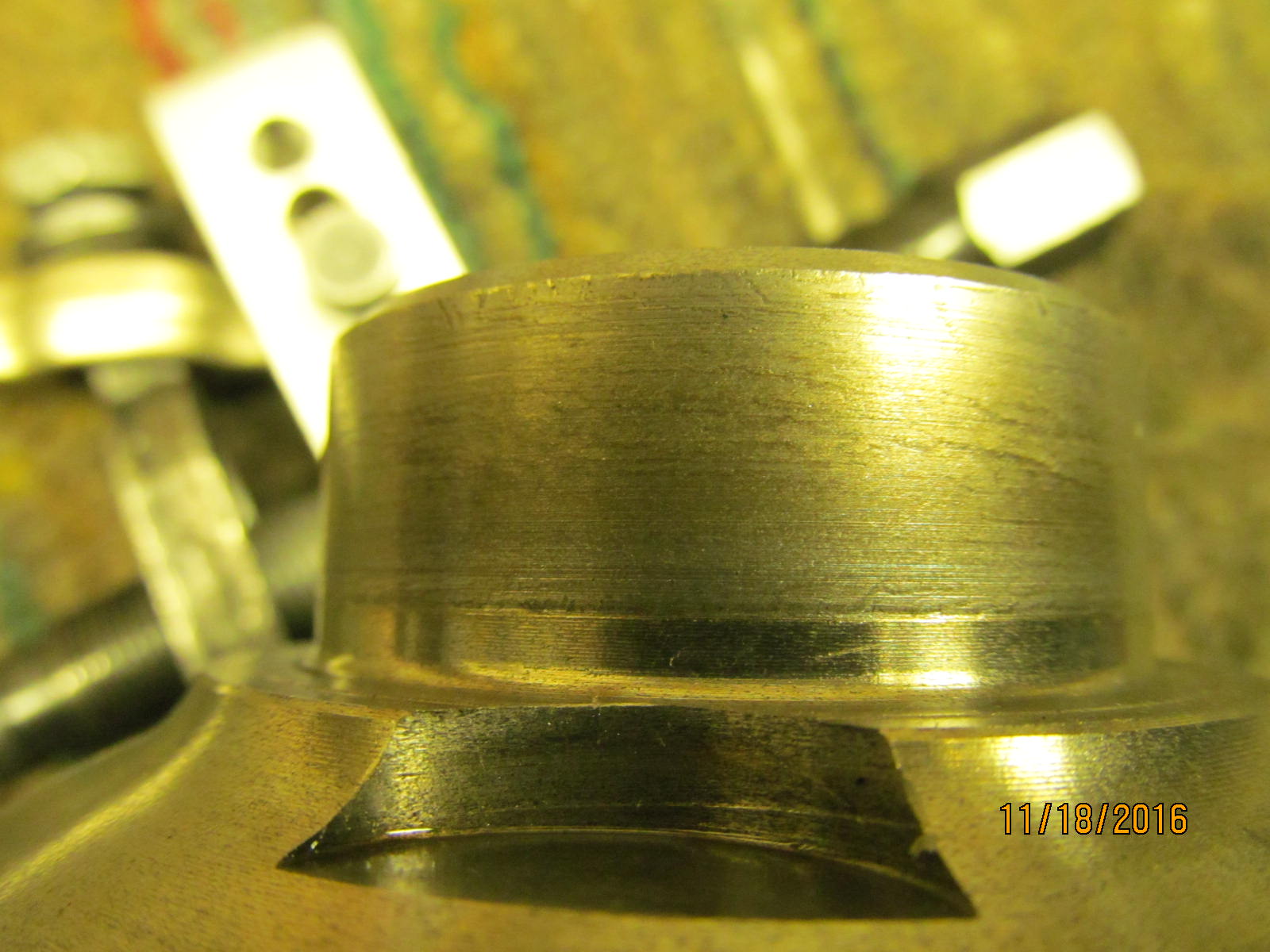

Journal #1....

|

|

|

|

Journal #2....they look a little rough but I noted the new bearings that went on did press on nice and tight

and that's what's important.

|

|

|

|

|

The flange had some bad grooves in it and some water damage. A new 29 spline flange will fix this.

|

|

|

|

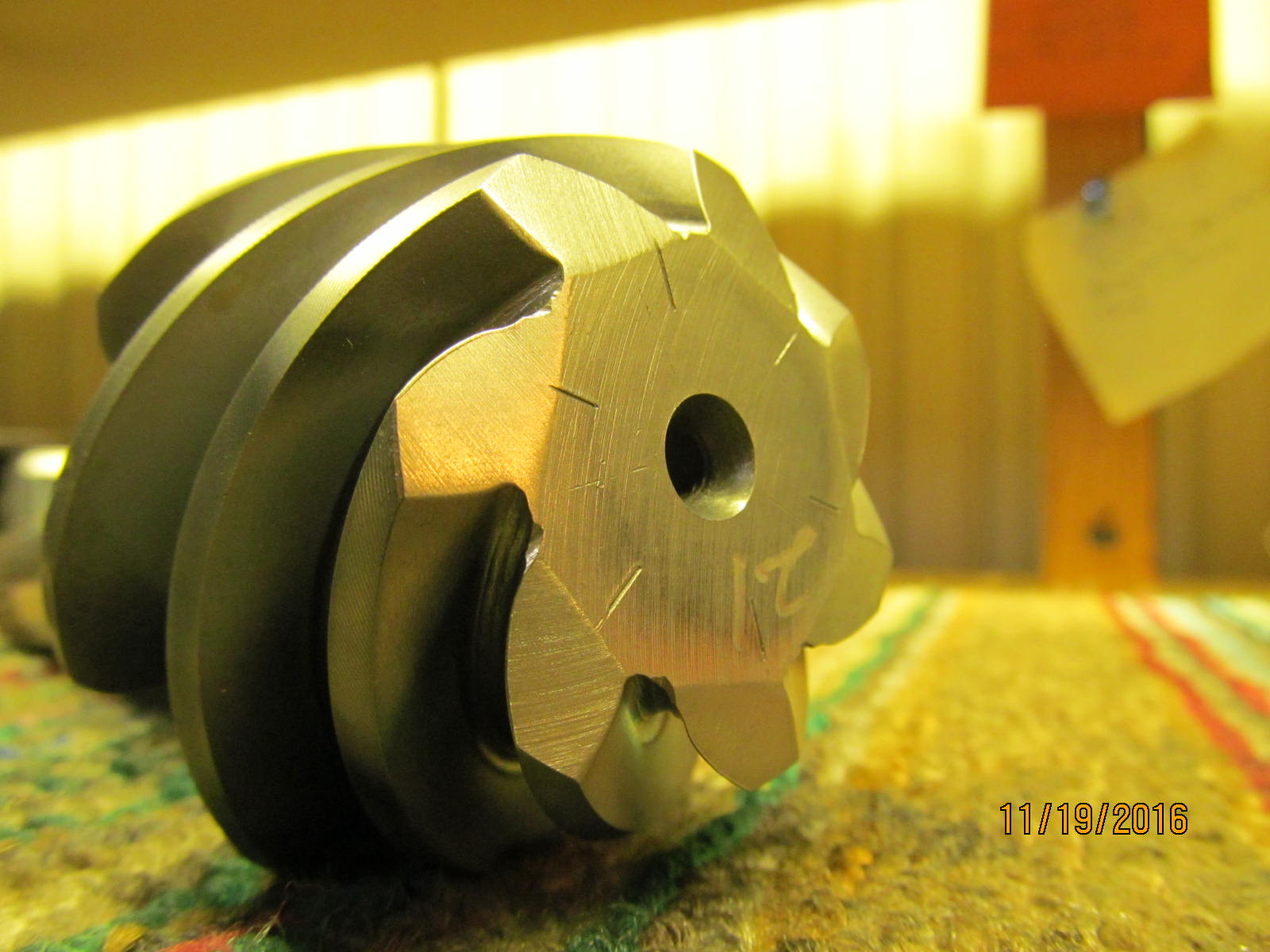

It did have a solid collar. The pinion end actually seemed set up well. No wobble in the pinion end.

It's just the case end that somehow shifted and self destructed.

|

|

|

|

|

Pinion shim was a typical .077"

|

|

|

|

|

Pinion races were normal.

|

|

|

|

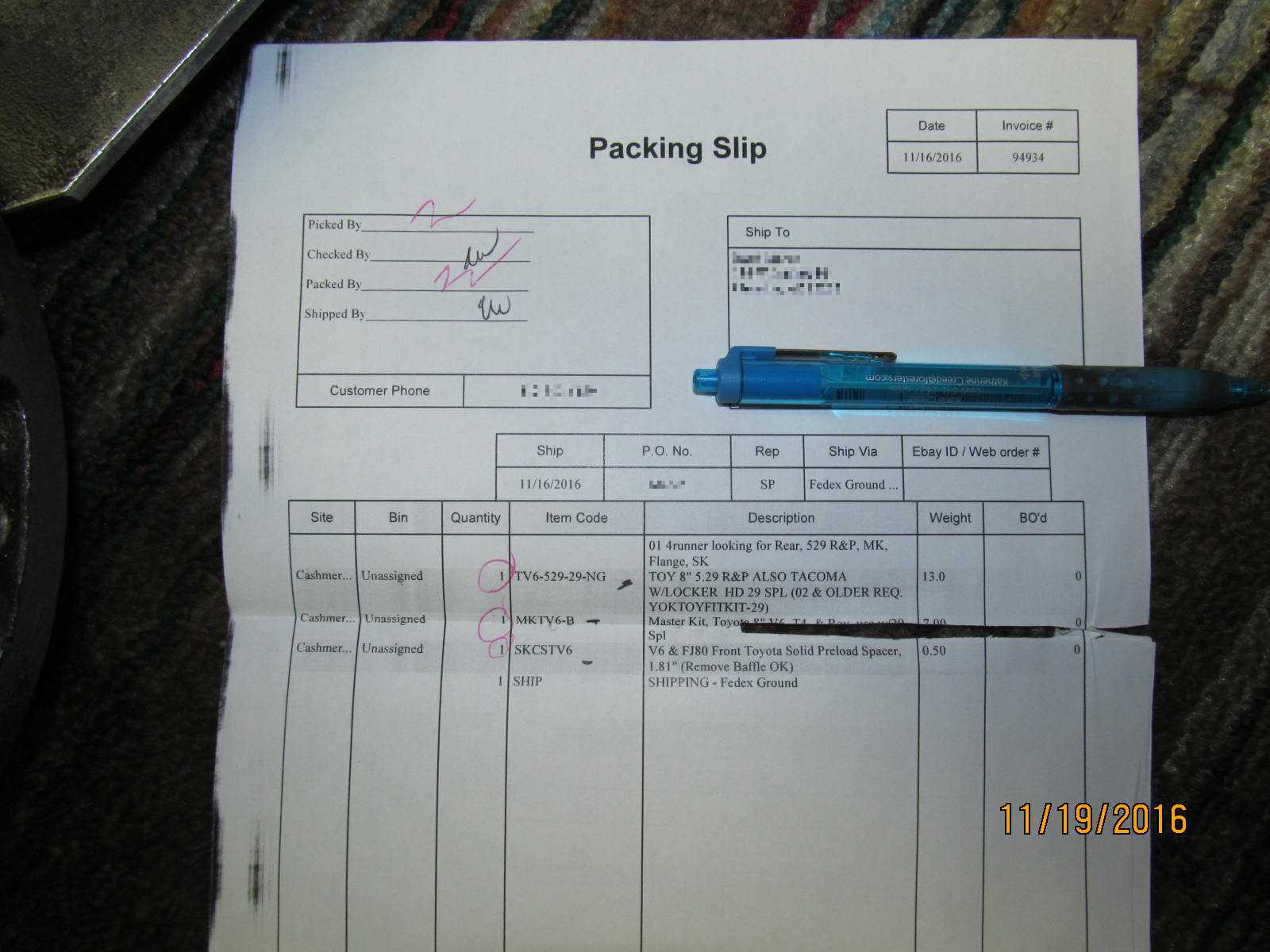

Cola is not so normal....likes to get in all my gear installs. Oh ya, she is announcing that she would

like to be present when the box of goodies from JustDifferentials.com for Jacob is opened up.

|

|

|

|

|

...........................

|

|

|

|

|

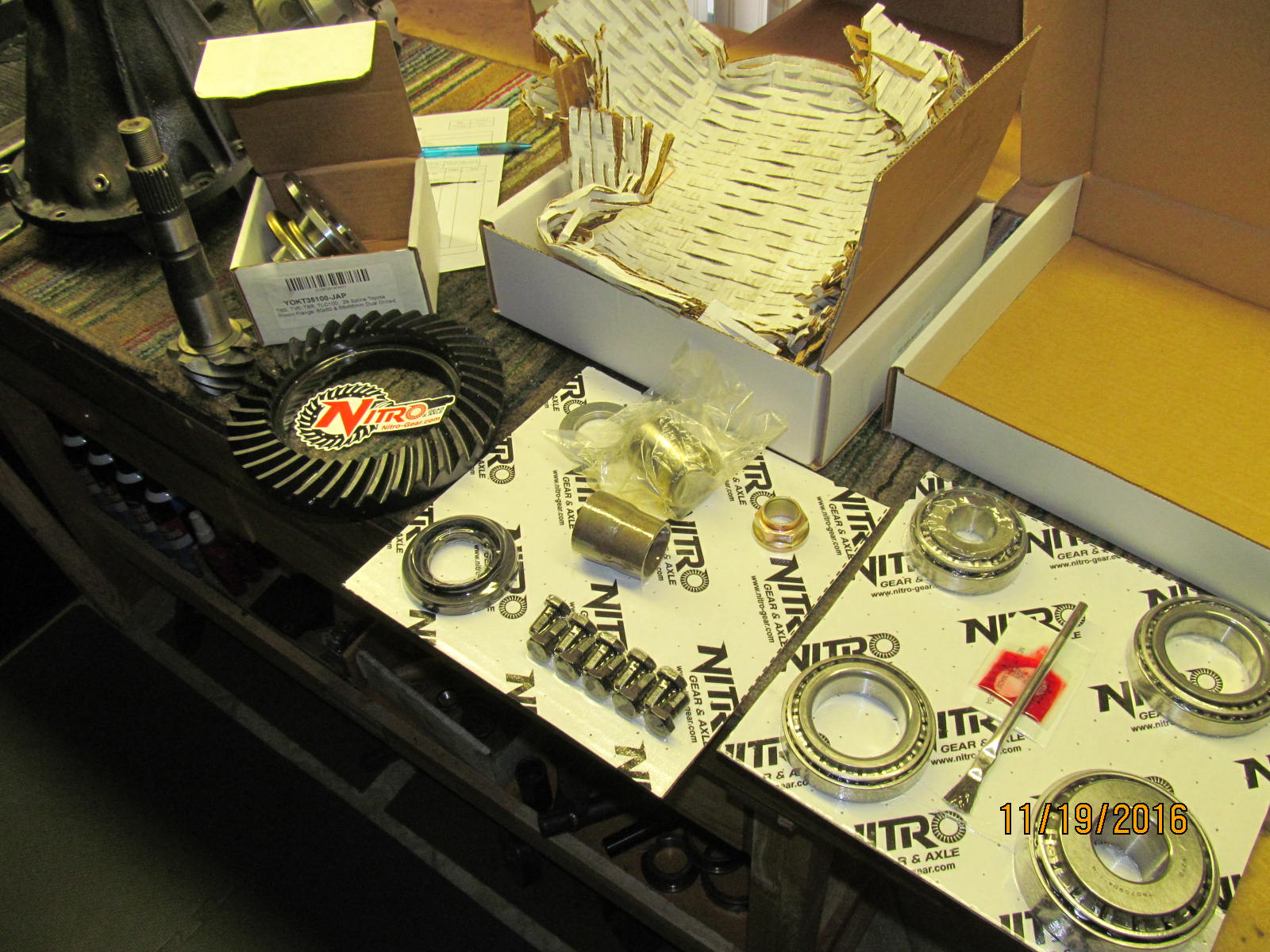

These will fix it up nicely....new flange/ring/pinion/master kit.

|

|

|

|

I used the sleeve lock on the carrier bearings even though the bearings were a good solid tight fit.

Now they'll never come off....maybe not even for the next installer :)

|

|

|

|

|

What the heck....used the stuff on the pinion races also. I'm on a roll.

|

|

|

|

|

The new Nitro 529 ring checks good....same with the mounting surface on the ARB case.

|

|

|

|

|

Blue loctite and 70 ft/lbs.

|

|

|

|

|

I also used the flapper wheel....I clearanced them "extra good".

|

|

|

|

|

The .077" shim is pressed on with the new Koyo bearing.

|

|

|

|

|

The pinion is mounted up in the 3rd...

|

|

|

|

|

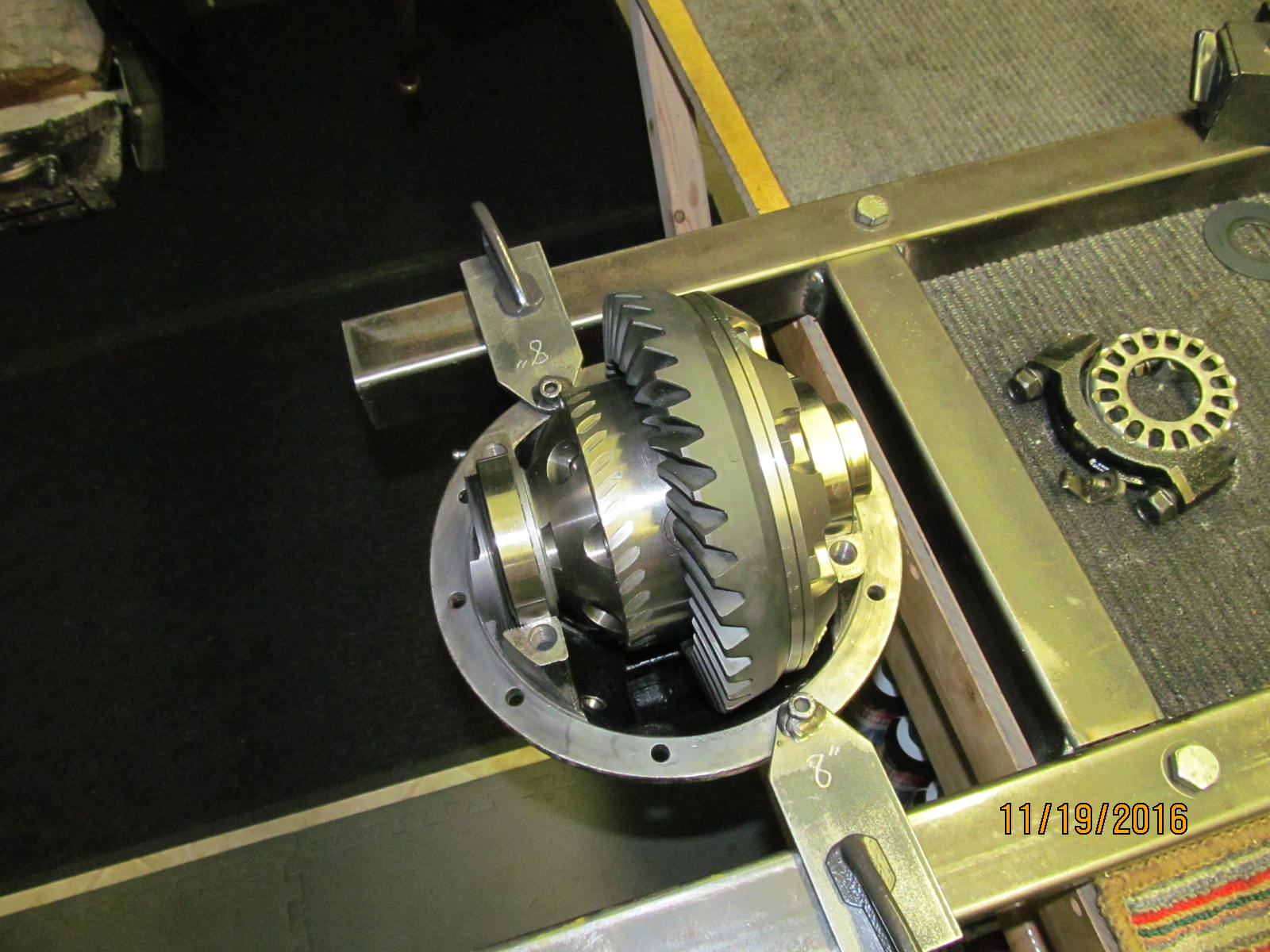

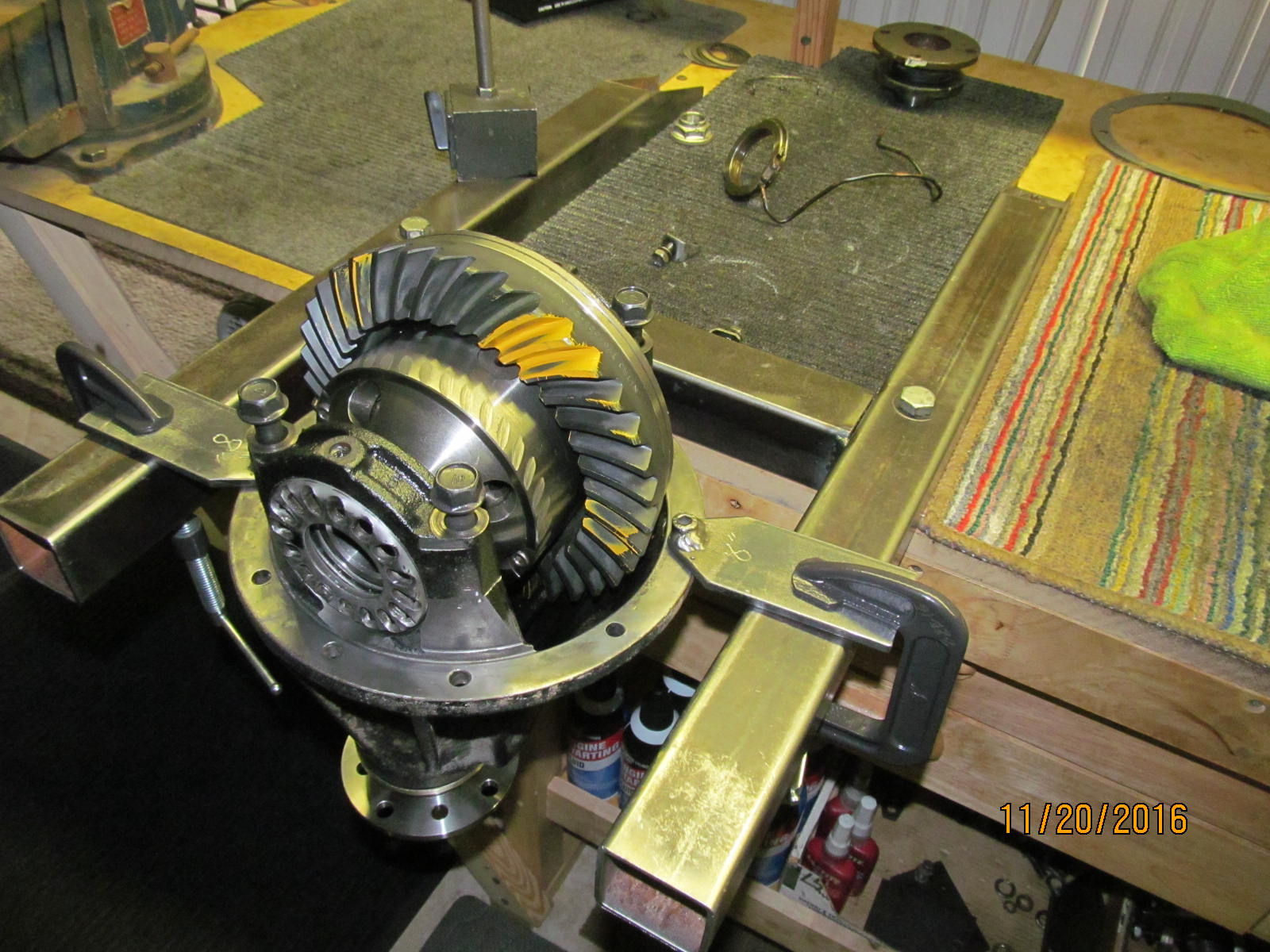

The ARB case is installed and adjusted for about .007" backlash...

|

|

|

|

|

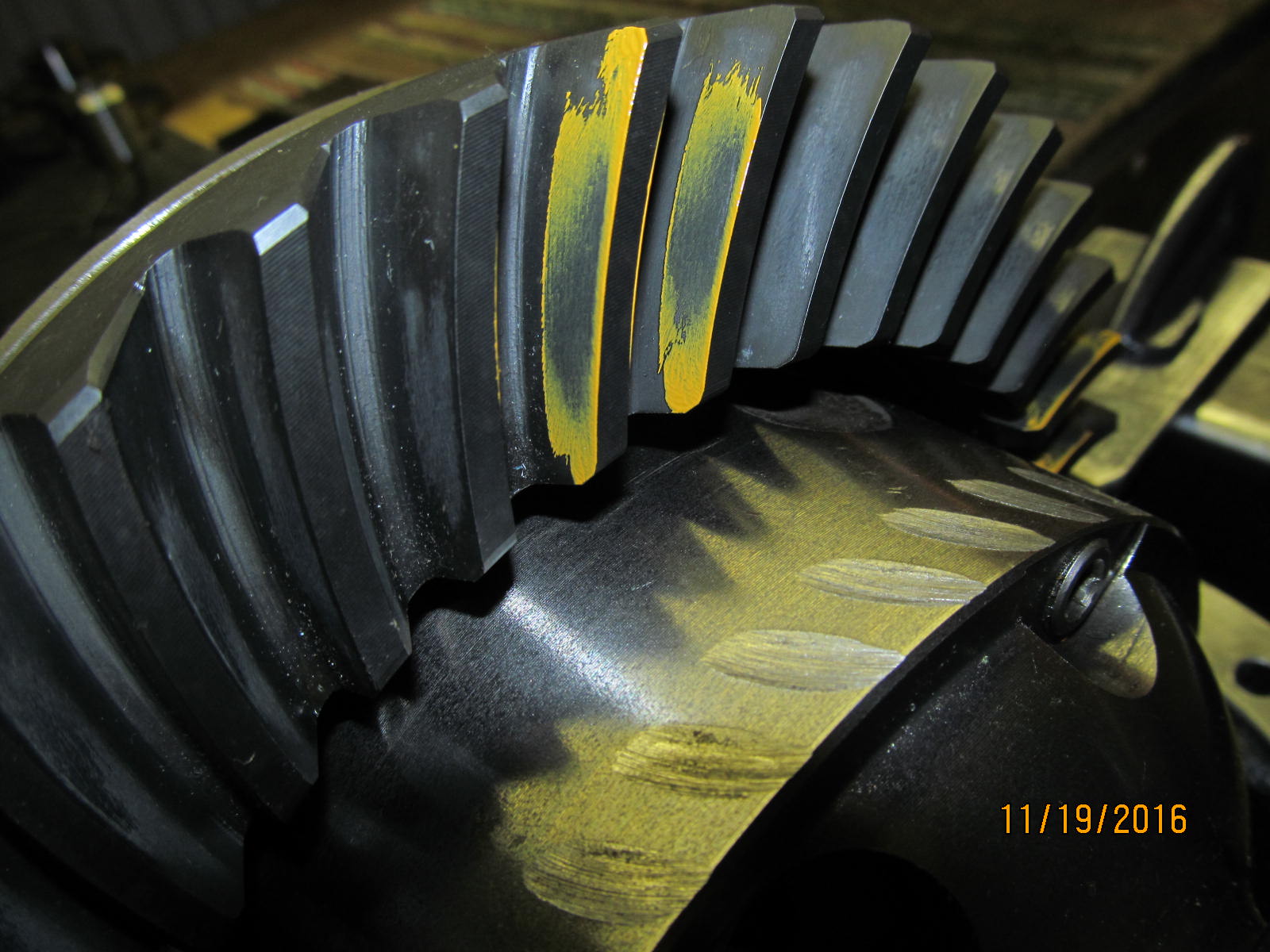

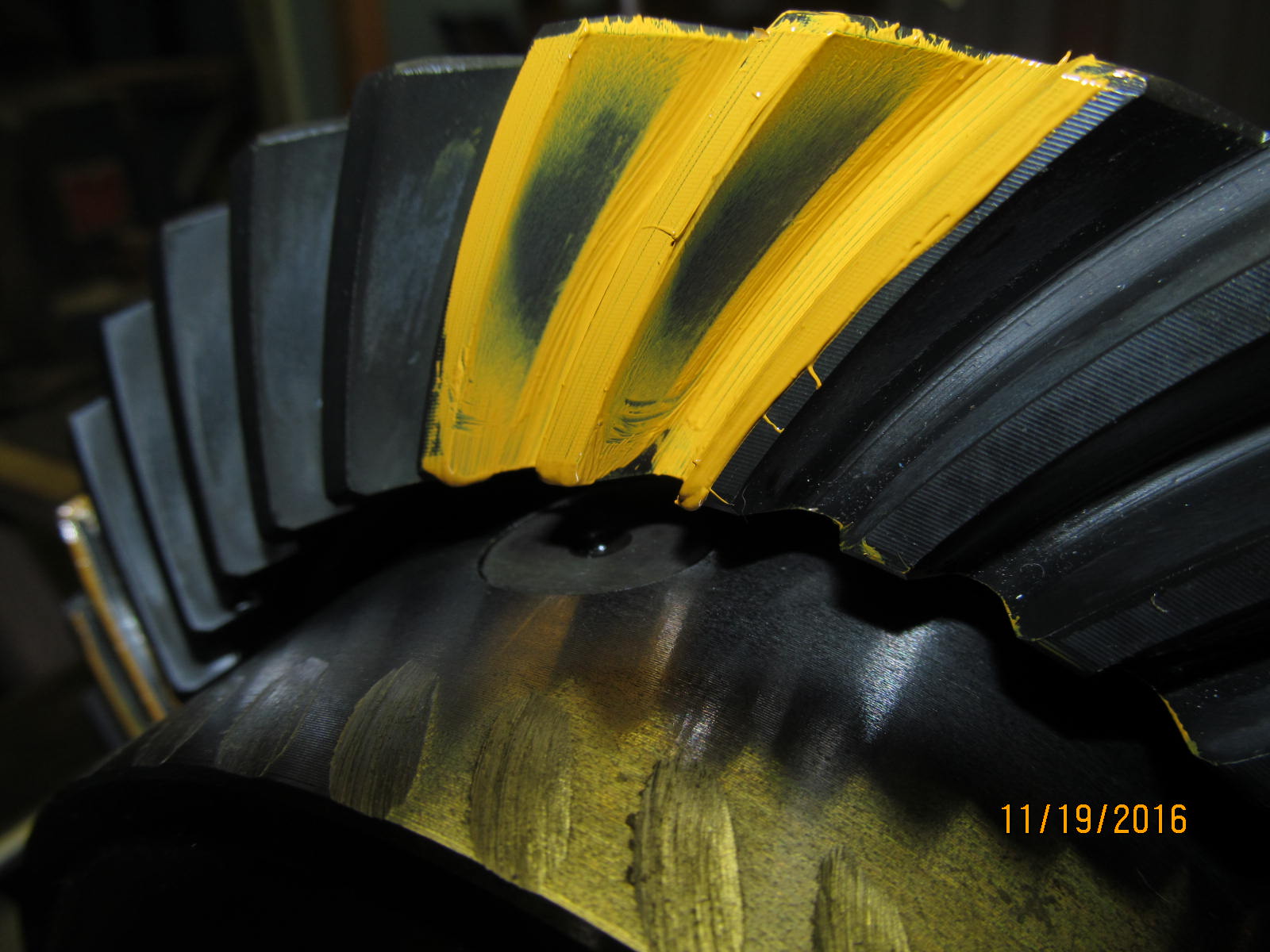

The painted pattern might suffice for some shops but I can see that this drive pattern is a bit shallow.

|

|

|

|

|

Coast

|

|

|

|

|

Drive...reverse painted.Coast....reverse painted.

|

|

|

|

|

Coast....reverse painted.

|

|

|

|

|

Drive on the pinion tooth....the comet tail is tucked in hard to the root of the tooth.....means it's shallow.

|

|

|

|

|

............................

|

|

|

|

|

Tear it all back down.....

|

|

|

|

|

....remove the pinion bearing.

|

|

|

|

|

Use a thicker pinion shim totalling .084" (7 thou deeper).

|

|

|

|

|

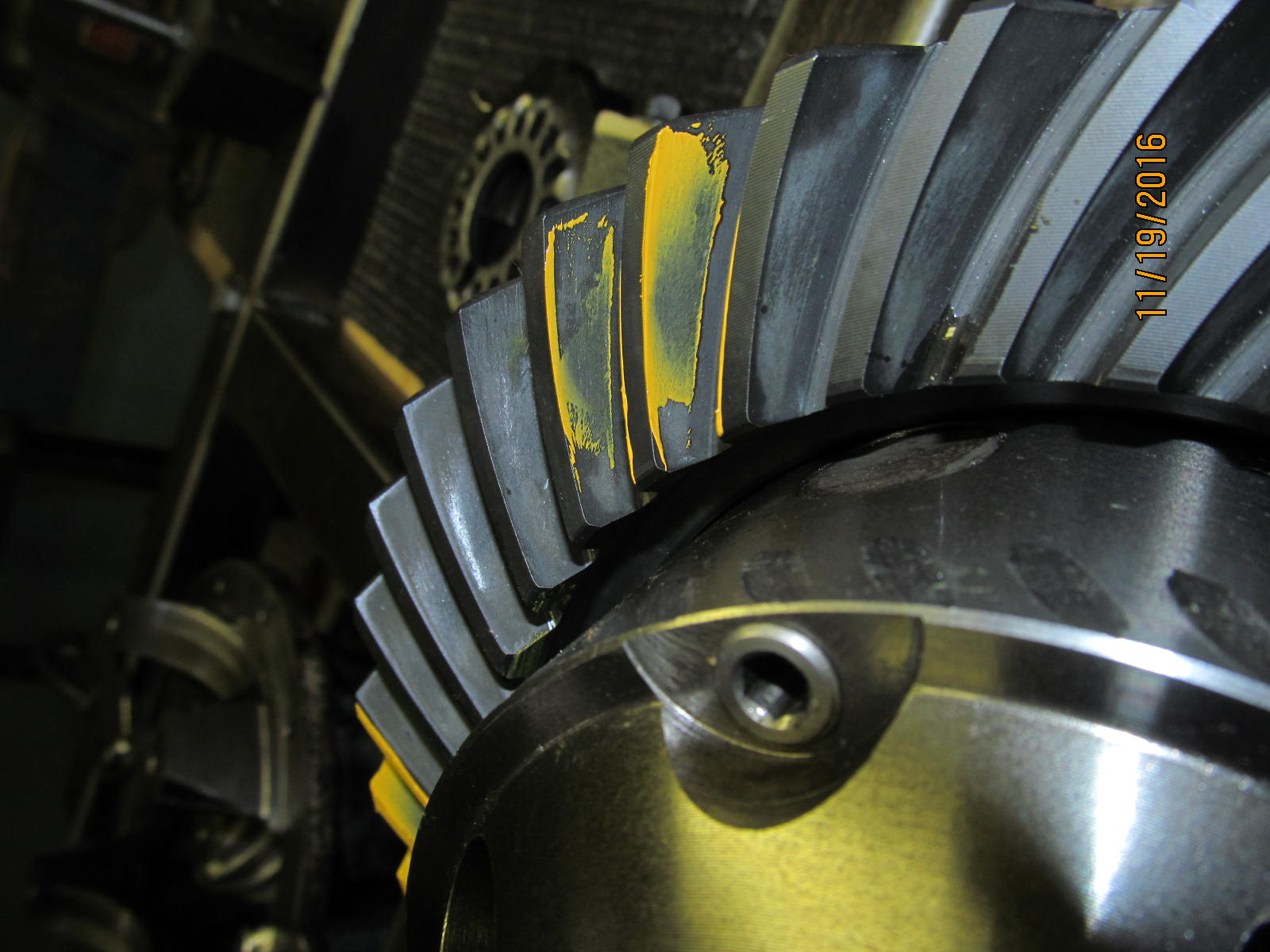

Oh ya...definitely deeper.

|

|

|

|

|

Coast says good.

|

|

|

|

A lot of the time, the reverse paints present a better picture of what's really happening.

This drive pattern says it's a keeper.

|

|

|

|

|

Coast...reverse painted.

|

|

|

|

|

Much better. The comet tail is fluffing to the center almost. Nice.

|

|

|

|

With the pinion depth nailed down now the solid collar can go in.

Took me only 3 times to get the preload just right.

|

|

|

|

|

The rubberized seal goes in next.

|

|

|

|

|

Tap tap. Fully flush.

|

|

|

|

|

A nice 11 in/lbs of PPL.

|

|

|

|

|

DING!! and the pinion end of things is complete.

|

|

|

|

|

On the final home stretch and I'm making absolutely sure that the threaded wheel adjusters are properly seated.

|

|

|

|

|

70 ft/lbs.

|

|

|

|

Backlash measured and recorded in 20 places and .006" was the minimum I noted.

Plenty of carrier bearing preload also, of course. The torque on

the 2 tabs was verified at 10 inch/pounds.

|

|

|

|

|

Pumped up the ARB to 100 psi with my Pepboys 12v special and all was good.

|

|

|

|

|

Data is logged onto the ring.

|

|

|

|

|

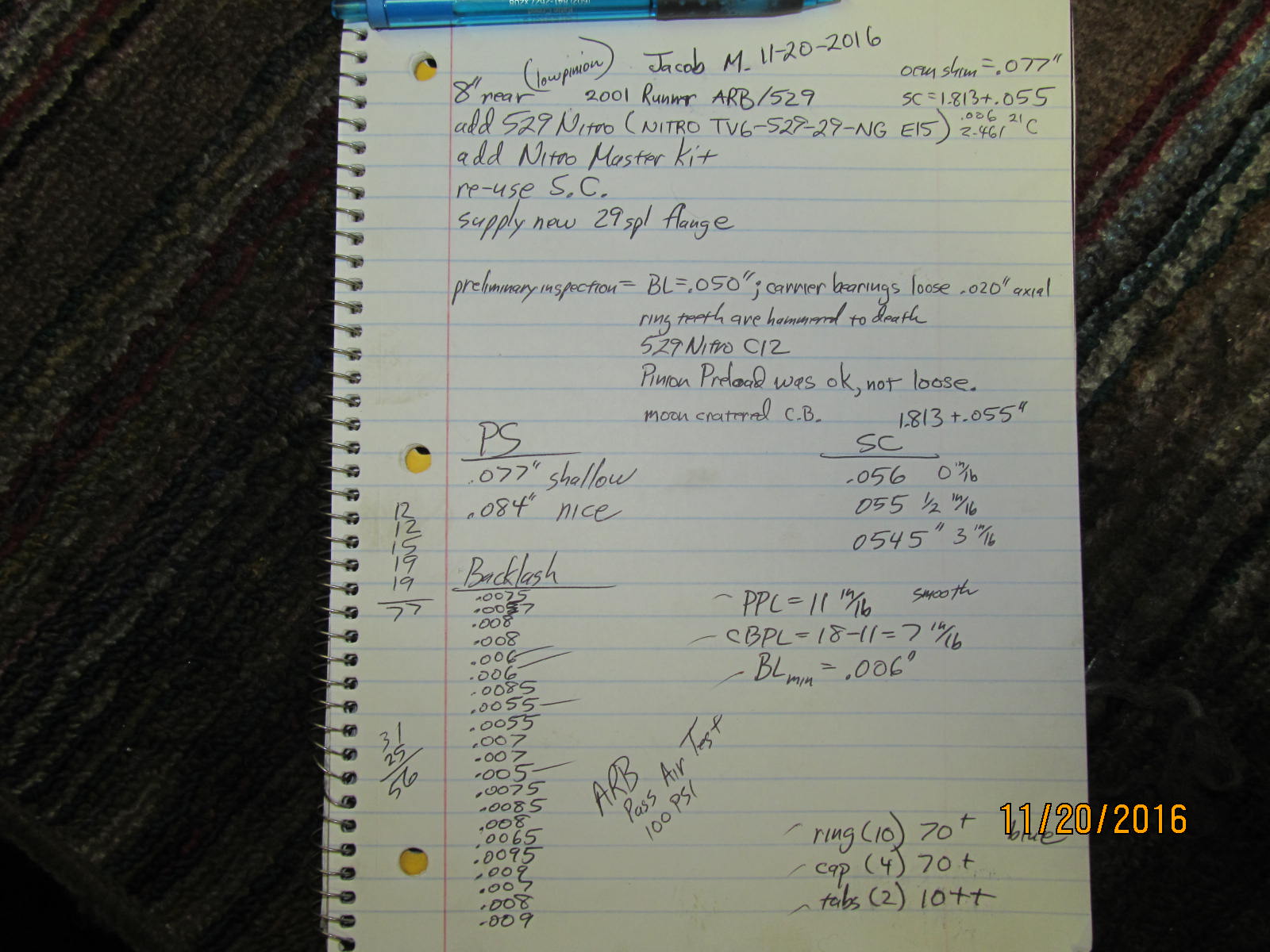

Snapshot of the notes.

|

|

|

|

Packed up in a double box and ready to go back to Jacob

12-6-2016....update....Jacob reports back...... "The 4runner is doing amazing! I am most of the way through my

break in and will be draining and checking fluid this weekend. Its smooth as butter!"

|

|

|

|