|

Jay from Edmonton, AB, Canada gets 488's, spool, new aftermarket diff housing.

|

|

(68 BIG pics loading)

|

|

NOV 17 2016

|

|

|

Jay supplied all the product including the new aftermarket diff housing. Jay had actually

sent 2 diffs....1 in the grey plastic container and the other in another plastic container.

As shown, the other diff arrived in a heavy duty cardboard box which seemed strange. Numerous

phonecalls revealed they damaged the plastic container and had to rebox.

write up for diff #2 (the 488 elocker)

|

|

|

|

|

Double boxing the diffs that are sent to me is still the way to go.

|

|

|

|

|

Items are laid out.

|

|

|

|

|

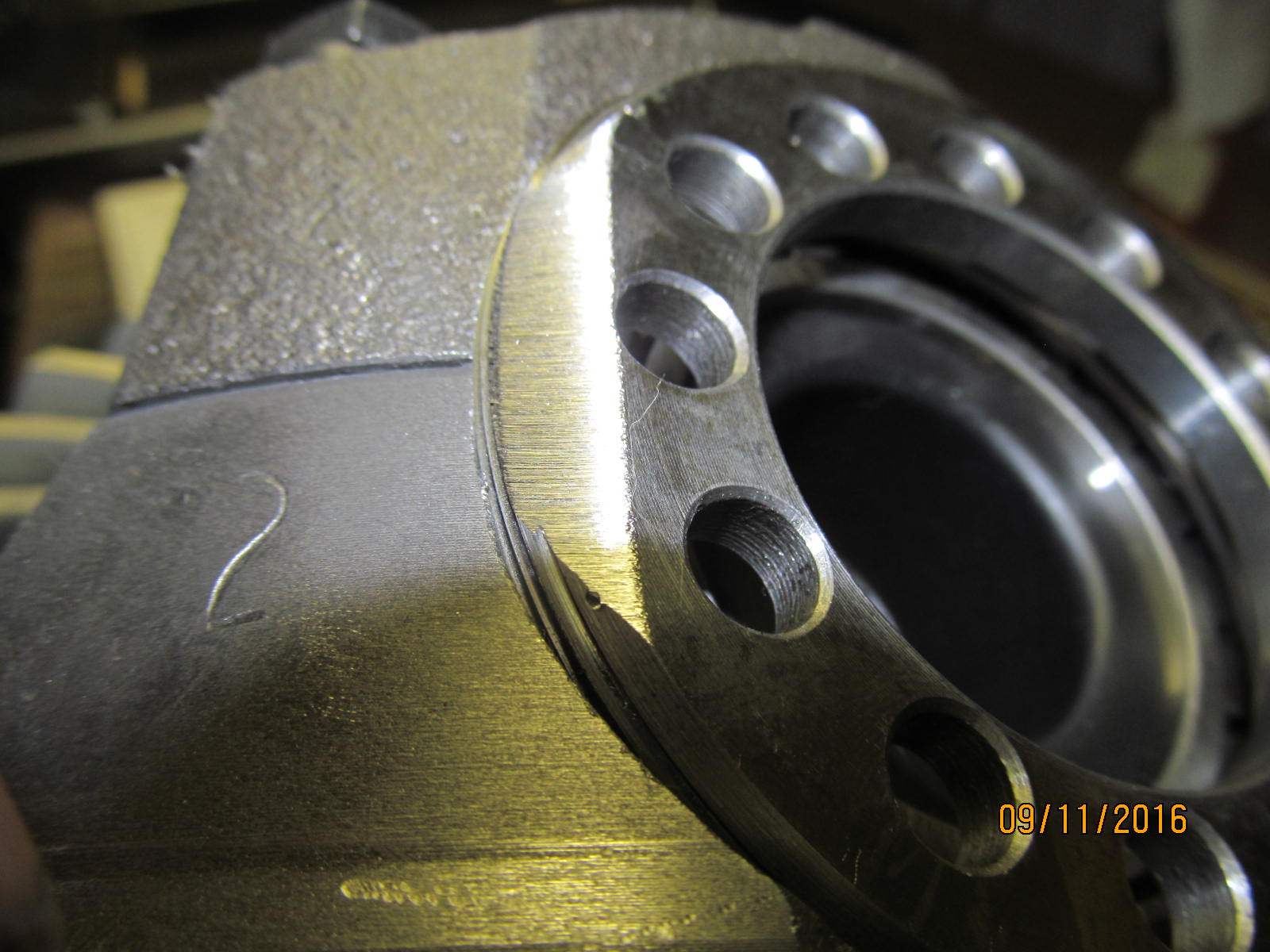

Start with the ring gear....verify there were no burrs or high spots.

|

|

|

|

|

Blue loctite and torque to 70 ft/lb.

|

|

|

|

|

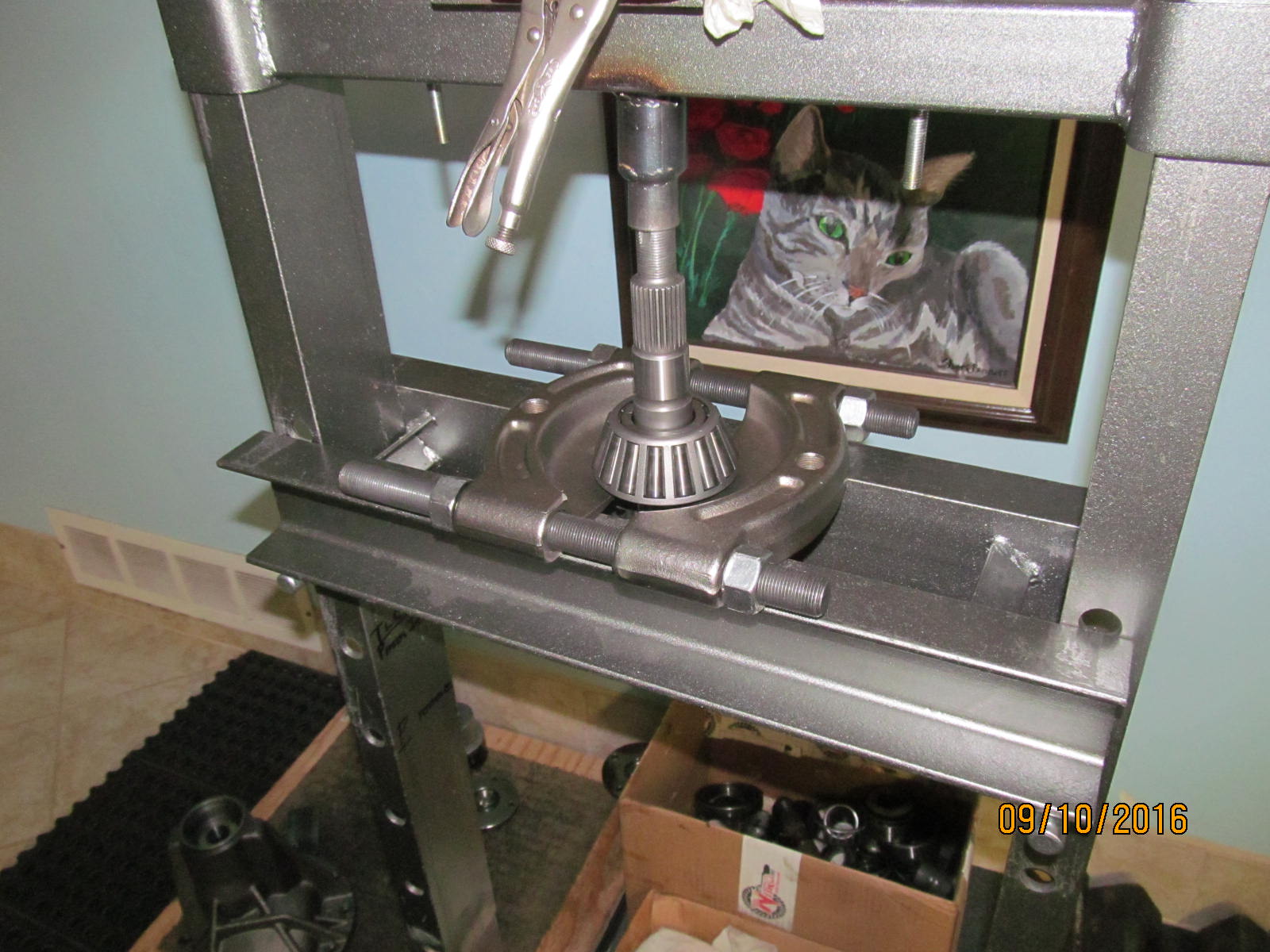

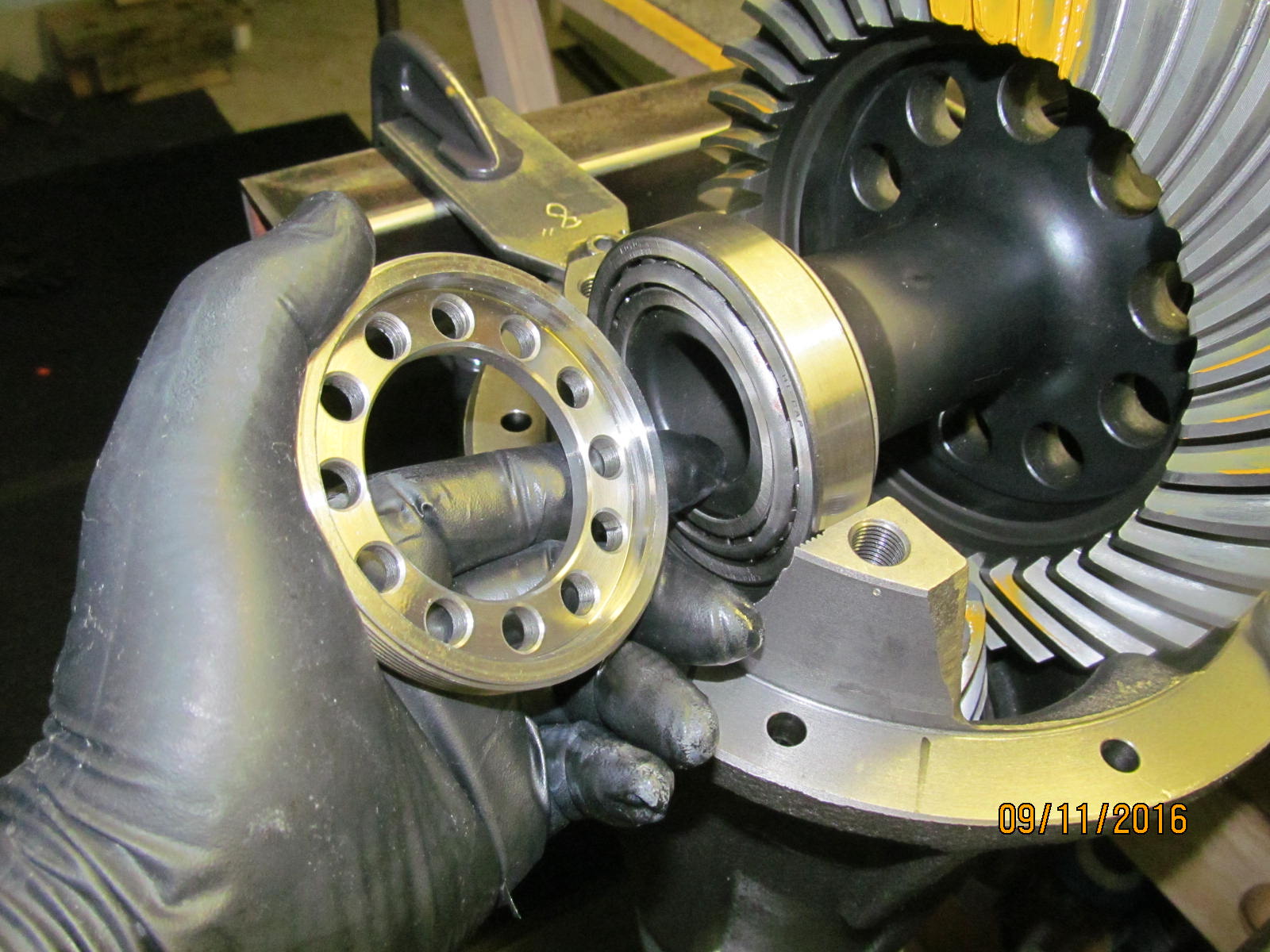

Then the new carrier bearings are pressed on.

|

|

|

|

|

This end is done.

|

|

|

|

|

Both pinion races can now be tapped in place.

|

|

|

|

|

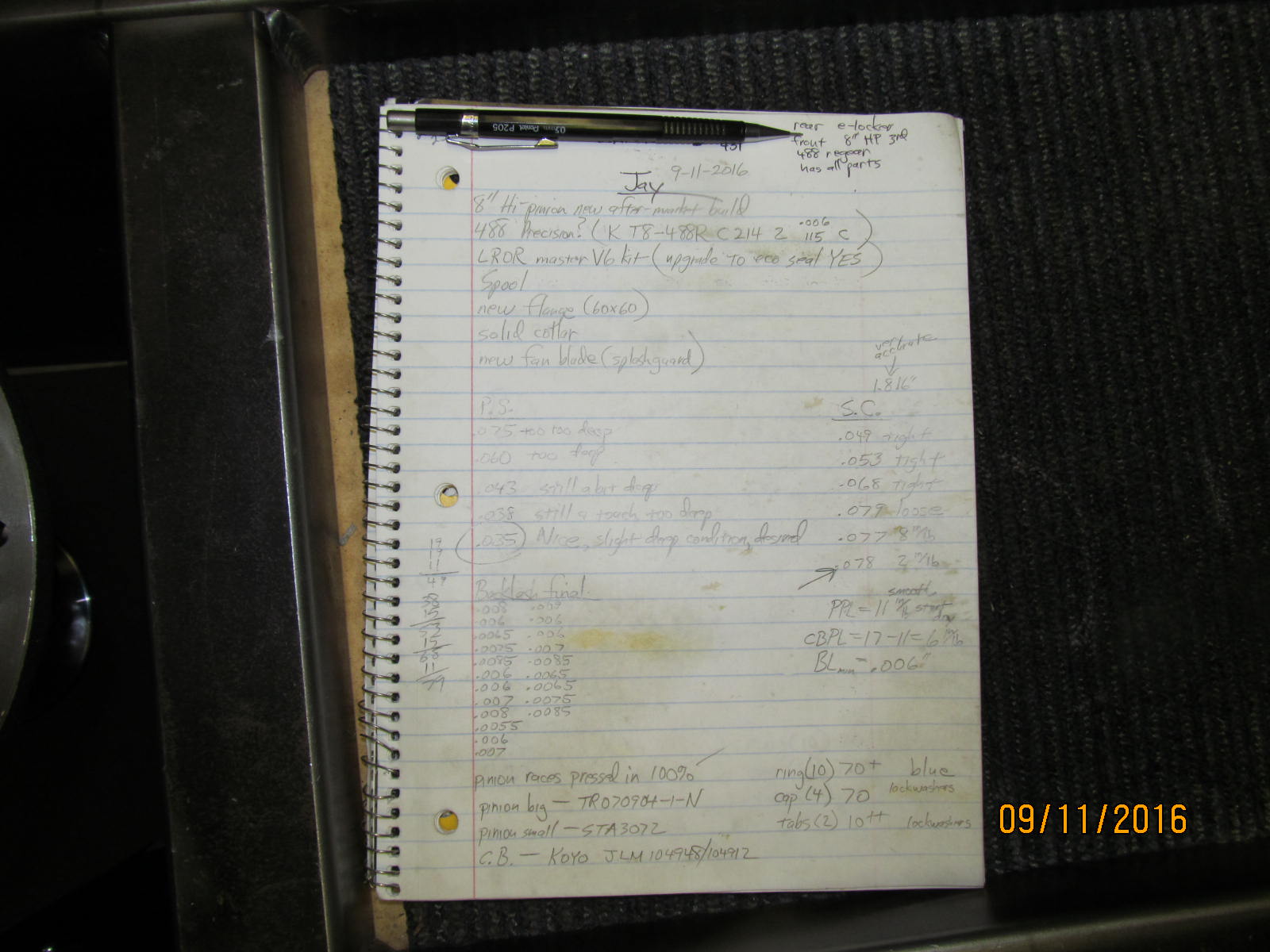

Selecting the starter shim. 075" will probably be a good bet.

|

|

|

|

|

Pressing the shim and bearing in place.

|

|

|

|

|

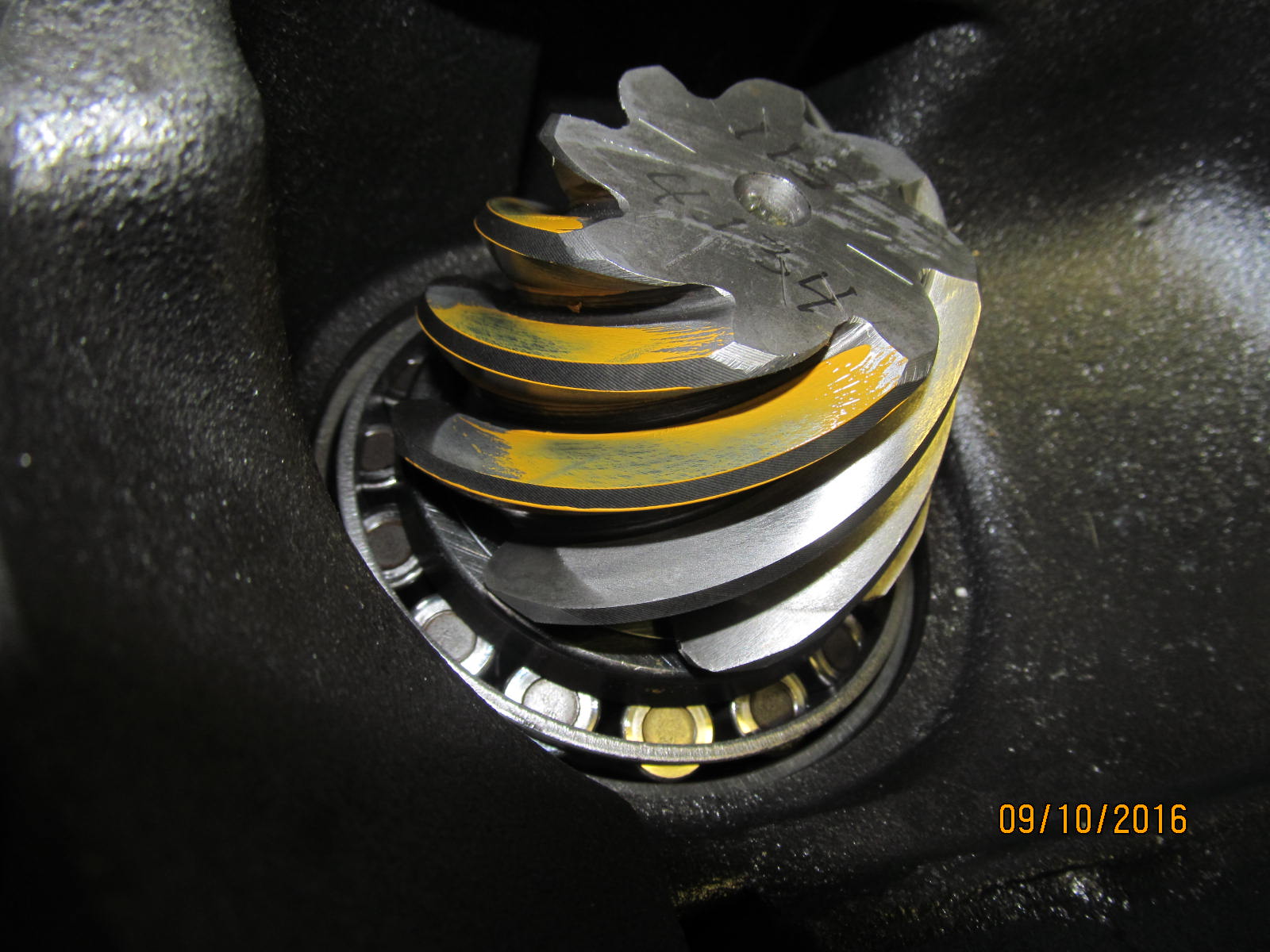

Mounting the pinion.

|

|

|

|

|

Mount the ring gear/spool assembly and dial in about .006" backlash.

|

|

|

|

|

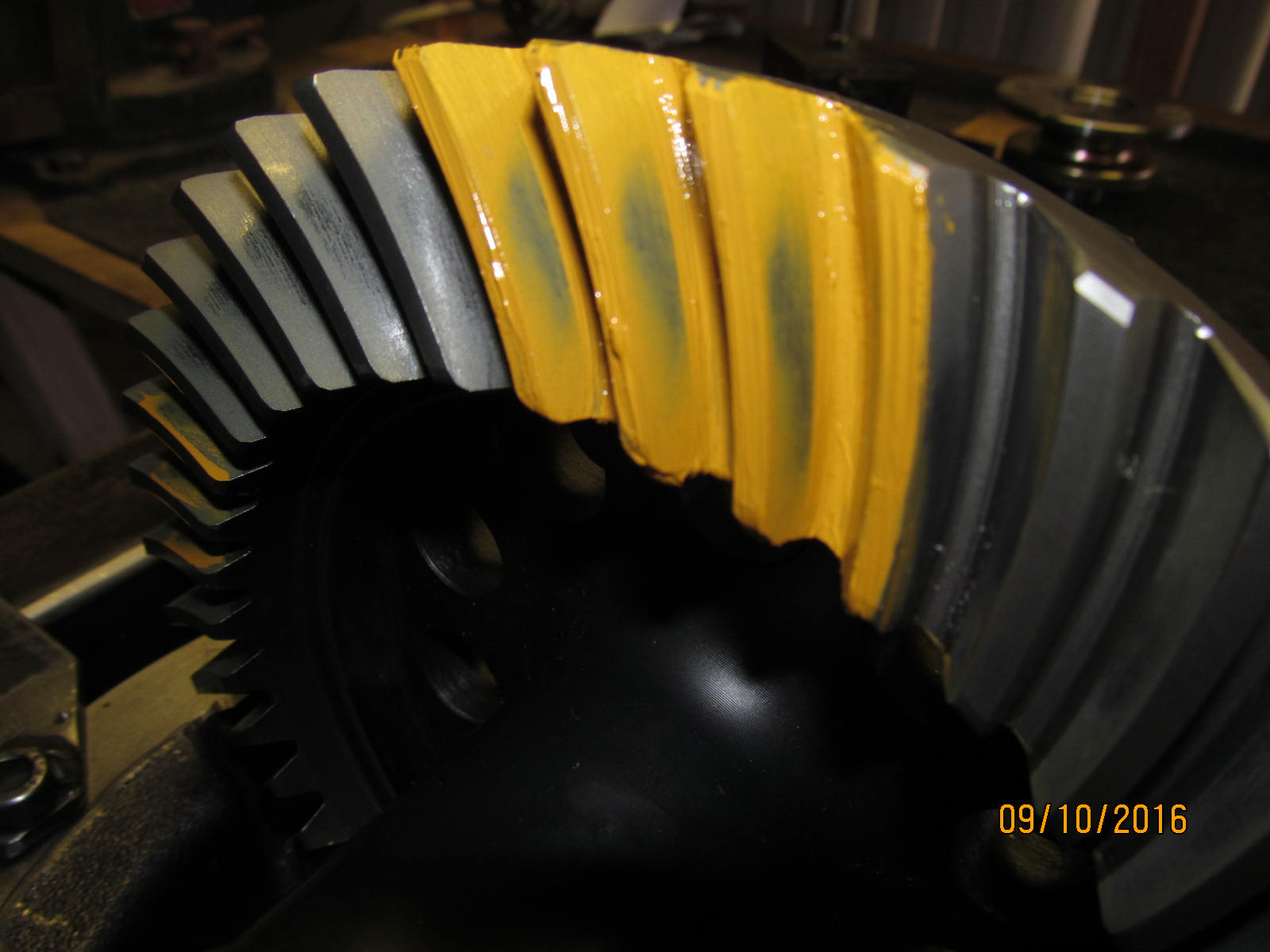

Wow....not only is it deep it's VERY deep.

|

|

|

|

|

Coast confirms that.

|

|

|

|

|

Drive on the pinion tooth is riding on the tips.....shallow on the pinion means deep on the ring.

|

|

|

|

|

Remove the pinion from the diff housing.

|

|

|

|

|

Press the bearing off...

|

|

|

|

|

Selecting a thinner pinion shim.....this time it will be 065.

|

|

|

|

|

065 is slightly better but way too deep still.

|

|

|

|

|

Same on the coast.

|

|

|

|

|

Tear down again....this is with 043".....still too deep but getting much closer.

|

|

|

|

|

..........................

|

|

|

|

|

Tear down again.....038" still deep but better.

|

|

|

|

|

Coast is better.

|

|

|

|

|

Drive side....

|

|

|

|

|

Pedrhaps jut a tad too deep still.

|

|

|

|

|

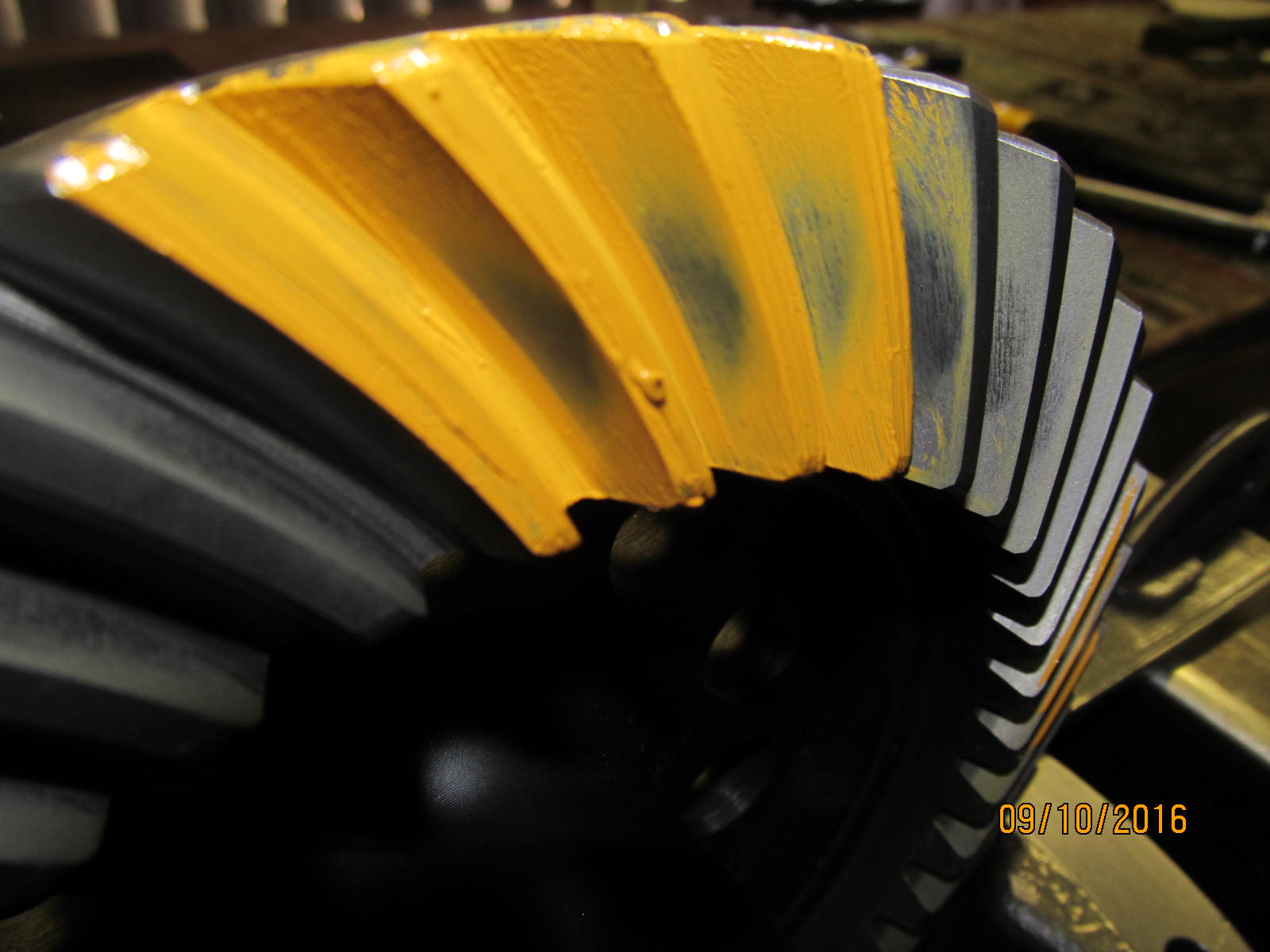

035".....I like this look. After 1 full row of Oreos it now kinda looks like the outline of a Ferrari.

|

|

|

|

|

I like the coast side...it's even in the center which doesn't happen all the time.

|

|

|

|

|

Drive.............

|

|

|

|

Looks like the comet tail is tucking in some........ 035 is the desired pinion shim. This is highly

unusual to have this small of a shim....a typical shim would be 080 and 035 is a long way from it.

Just the way this aftermarket bore hole was drilled.

|

|

|

|

|

Tucking in but not harshly to the root.

|

|

|

|

|

The Marlin seal on the right is extra insurance against leaks.

|

|

|

|

|

The aftermarket seal is "ok".

|

|

|

|

The Marlin eco seal has 3 sealing surfaces and the main bottom seal lip is riding in a

location that none of the other seals can reach.

|

|

|

|

|

Solid collar to be installed now.

|

|

|

|

|

........................

|

|

|

|

Getting the just right pinion preload involves re-shimming the solid collar numerous times

.....assemble then disassemble....assemble then disassemble. Note the shop flange is used for this operation.

|

|

|

|

|

This time it took 6 tries.

|

|

|

|

|

Now the Marlin seal can be tapped down evenly with the special tool.

|

|

|

|

|

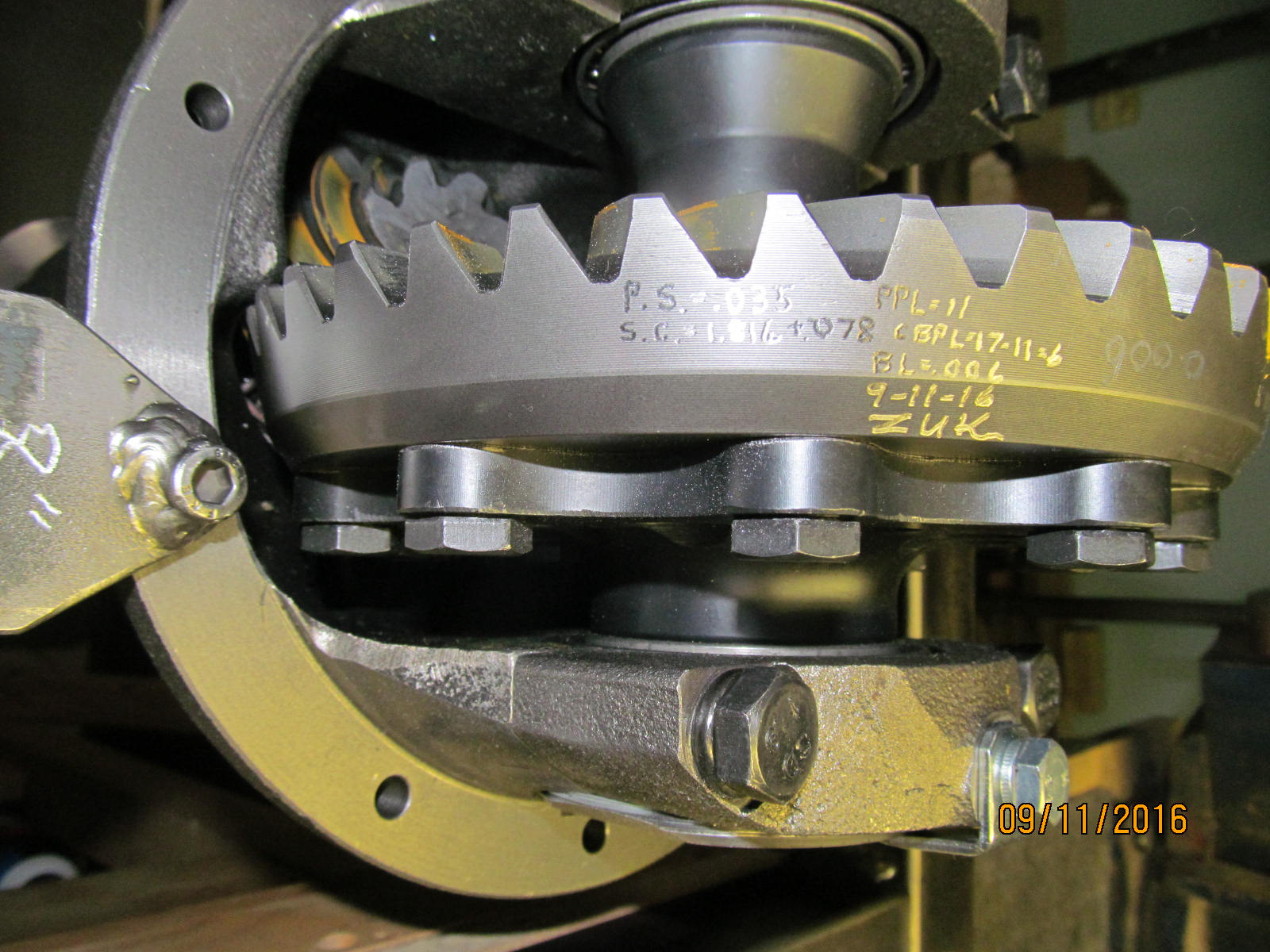

Final PPL checked in at 11 inch/pounds.

|

|

|

|

|

A low profile DING! takes care of this end.

|

|

|

|

|

..........................

|

|

|

|

|

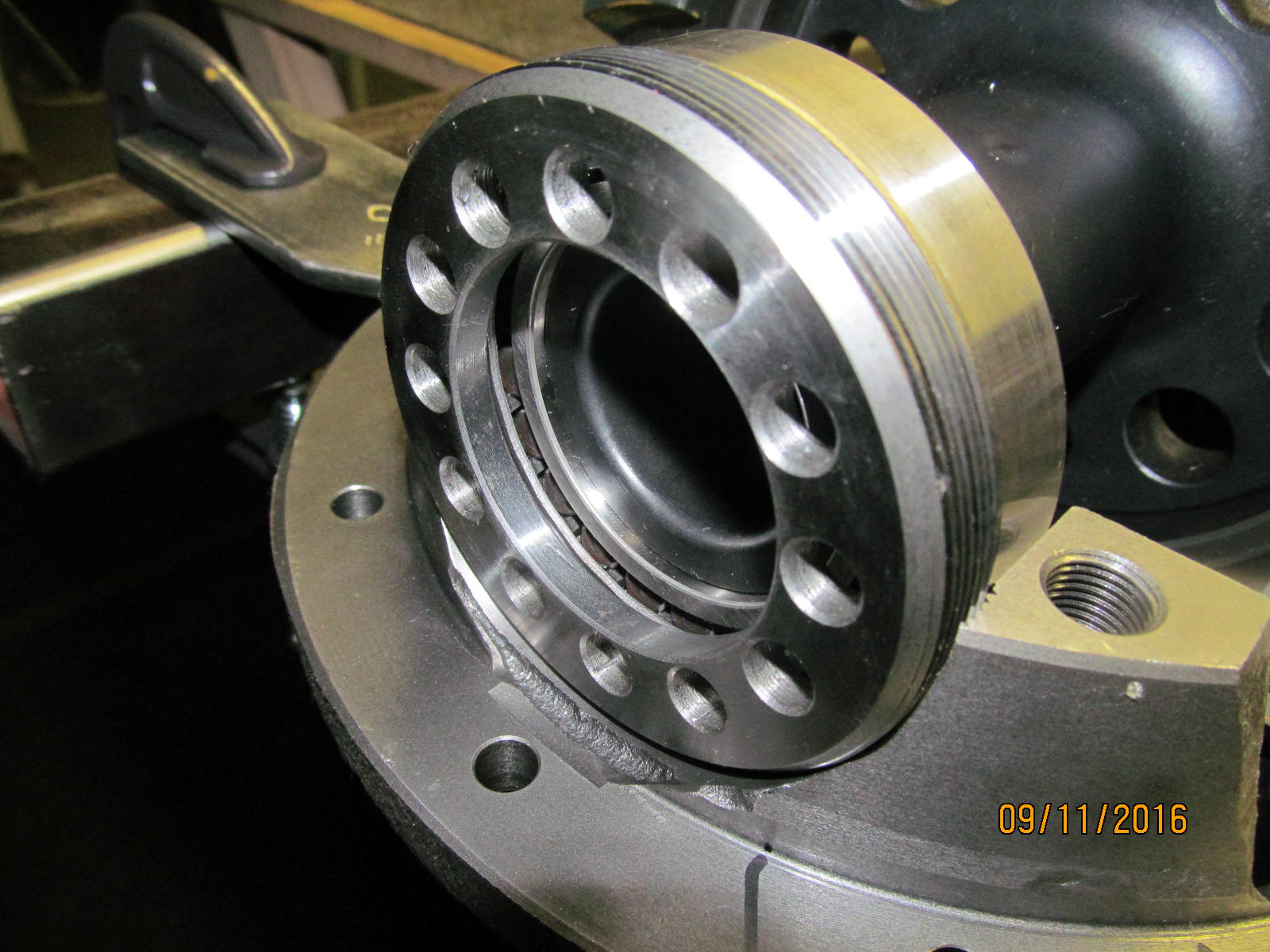

These wheel adjusters are well machined and very beefy.

|

|

|

|

|

.............................

|

|

|

|

|

70 ft

|

|

|

|

|

Backlash and carrier bearing preloads are dialed in.

|

|

|

|

|

Masking off the wheel adjuster, the sides can be clearanced with a flapper wheel.

|

|

|

|

|

...............................

|

|

|

|

|

..................................

|

|

|

|

|

.................................

|

|

|

|

The clearancing will allow the 3rd to fit into the axle housing hole.

10 ft/lbs on the 2 lock tabs.

|

|

|

|

|

Last final check and the drive side looks nice.

|

|

|

|

|

Coast.

|

|

|

|

|

Engraving the specs on the ring gear.

|

|

|

|

|

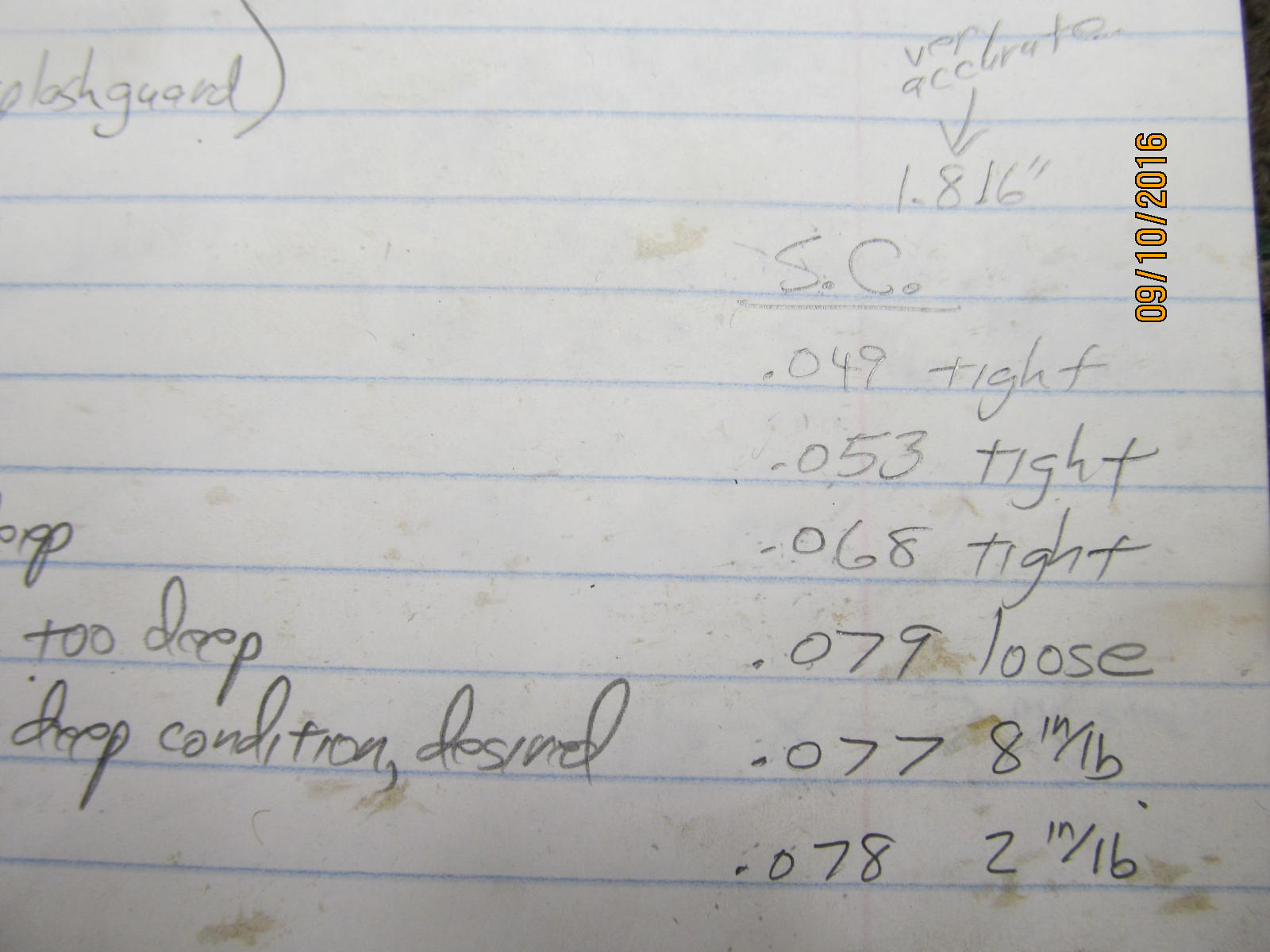

Notes taken.

|

|

|

|

|

Nice looking hi-pinion 3rd.

|

|

|

|

|

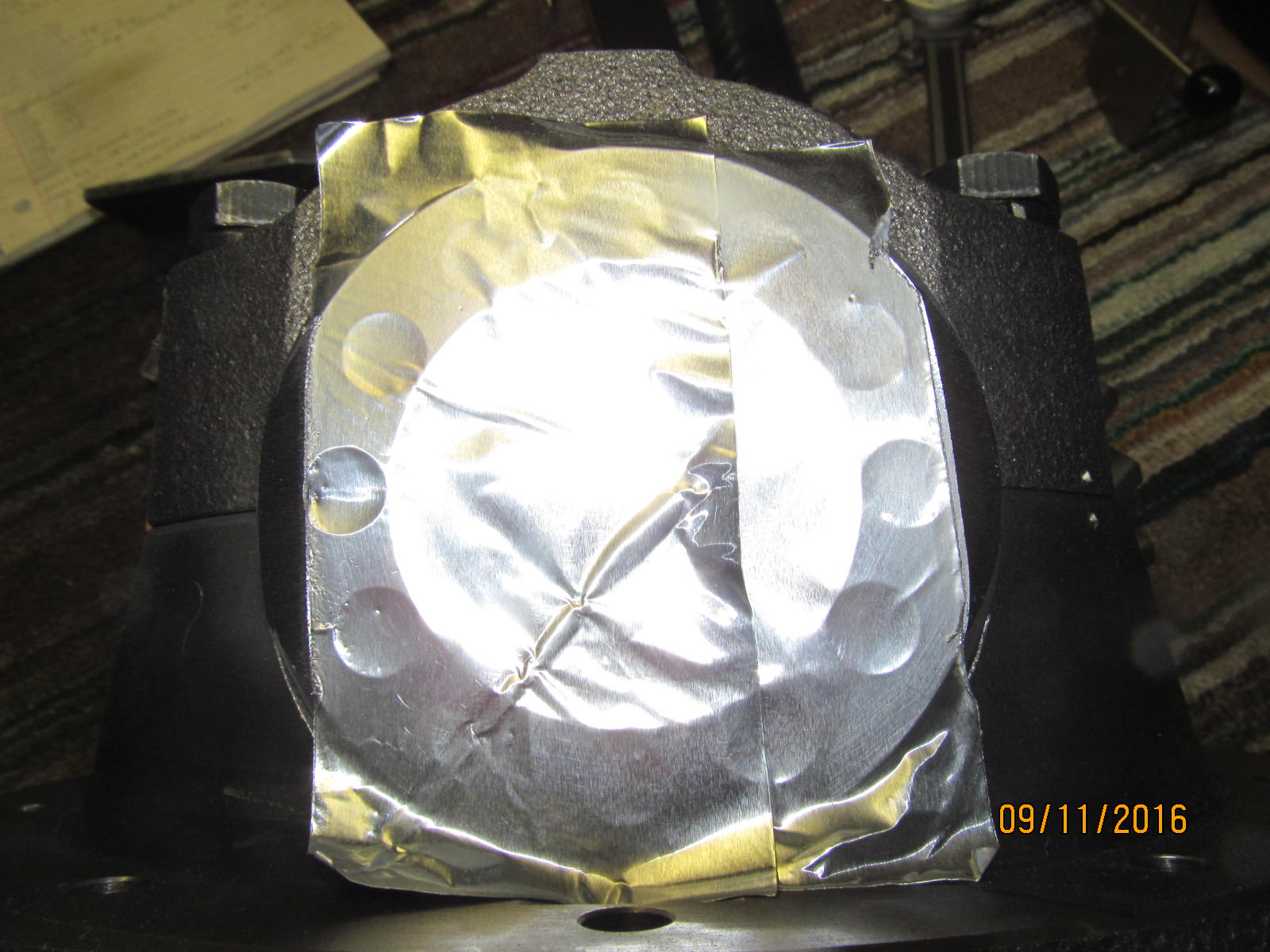

Sometimes, I use an old blanket to wrap the 3rd for the double box.

|

|

|

|

|

Some extra cushioning.

|

|

|

|

|

.................................

|

|

|

|

|

3rd dropped in.....

|

|

|

|

|

More cushioning on the topside...

|

|

|

|

|

Now to final wrap the box 6 or 7 times with a heavy duty tape and ready to go to Fedex.

|

|

|

|