|

Jason's 1993 pick-up still has the IFS front end but the over-all procedure is still the same. The main

difference is carrier bearing shims/washers instead of spanner adjusters. Here, I've already dis-assembled

the carrier.

|

|

|

A new master kit and a quality Precision ring and pinion are standing by.

|

|

|

The puller is secured in the vice while the wrench turns the old carrier bearings off.

|

|

|

The Precision 488 ring tapped on very nicely...not a hard press fit...but not so light that it fell on.

|

|

|

New carrier bearings are pressed on at the same time on the 10 ton press.

|

|

|

The same with the pinion races....both were done at the same time.

|

|

|

...

|

|

|

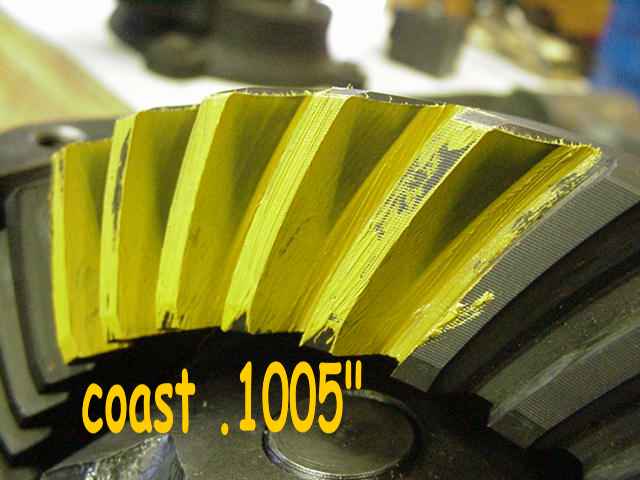

The new pinion bearing was pressed on with the .1005" original shim. As you can see,

my vice and the small press see good use for this process.

|

|

|

The pinion is now loaded into the carrier without the crush sleeve. The crush will be used in the very

end. Pinion pre-load will be set by carefully tightening the 24mm nut.

|

|

|

Lots of gear oil on both pinion bearings or the PPL readings will be meaningless.

|

|

|

This is the correct carrier bearing for this shim application. Notice how the race is the highest point?

I have received master kits in the past that had 'low races'.....that meant interference with the carrier bearing shims

and that meant it was a PITA to set the CBPL because the shim had to be tapped in at the same time as the case was

lowered in.

|

|

|

A lead filled rubber coated hammer helps here.

|

|

|

Both bearing caps were marked in such a way that there would be no doubt about the side or orientation.

|

|

|

The BL was zero when I re-used the factory carrier bearing shims. Removing the case is easy by using 2

crowbars.

|

|

|

Drive side looks deep.

|

|

|

coast agrees

|

|

|

Looks close.

|

|

|

Seems to still be deep. Camera went fuzzy on me this time.

|

|

|

Still looks good.

|

|

|

Looks good but can't pull it any farther away from the outer heel even with the outer limit BL at .0085". This is what will

be used.

|

|

|

The case had to be removed again to re-insert the new crush sleeve. Red loctite was liberally applied

to the clean pinion threads. Even with the long 4 foot cheater bar the force required to crush the sleeve were

mucho. Anti-sieze on the threads would make it about 30% easier to crush but today we are on the Loctite wagon.

|

|

|

After crushing it and verifying 14 in/lbs, it was time to pound the case in the carrier and torque the

bearing cap bolts to 75 ft/lbs.

|

|

|

One last thing to do...

|

|

|

...carefully tap the new axle stub seals supplied in the master kit in place.

A light coating of gear oil on the rubber to prevent a dry start-up.

|

|

|

I supply a paper tag with most of my gear installs that lists all the specs that I set the install to. I usually also

add the specs to the ring gear via a dremel tool.

|

|

|

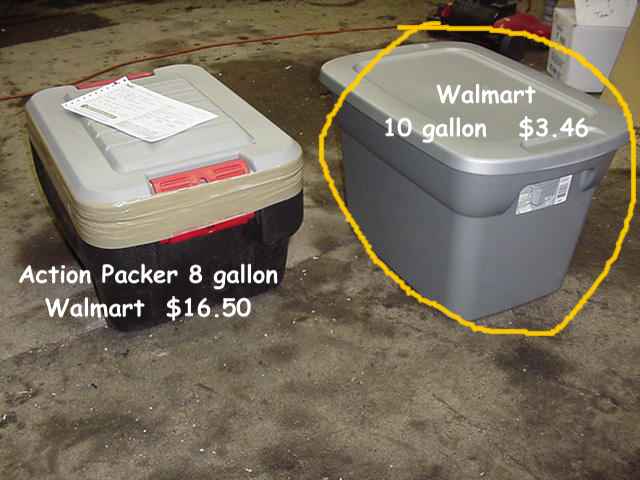

I've received a number of gear sets in the mail protected by 8 gallon Action Packer containers like the

one on the left(perfect size).The packers run about $17. But, recently, I was in Walmart and found a

reasonably strong 10 gallon tote for $3.46!

|

|

|

I would like to recommend these for sending 3rds to me....they are cheap and strong enough for multiple trips.

Sure helps me when I have a container like this ready to go.

|

|

|

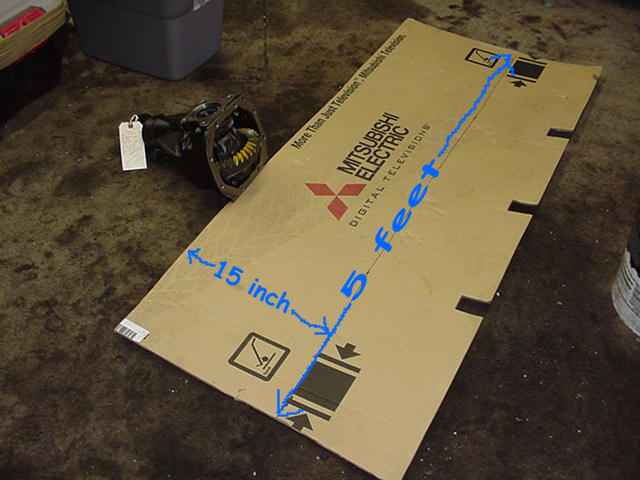

Lots of room in the tote....The 3rd would rub thru the bottom if it were shipped

like this so the trick is lotsa cardboard...

|

|

|

Find a long box....like a refrigerator box and cut a 15 inch wide strip about 5 feet long.

|

|

|

Wrap the carrier like a burrito and tape it. I like to use the brown stretchy packaging tape.

|

|

|

Wrap up misc. cardboard in both ends...

|

|

|

Stuff a few disc shaped cardboard pieces on this end....

|

|

|

...and tape up both ends securely.

|

|

|

3 or 4 cardboard layers on the bottom and all around the sides. Place the lid on and run the stretchy tape around

about 5 or 10 times and it's well secured.

|

|

|

Total weight...IFS front carrier open diff....secured like this was 57 pounds. This one will

cost about $100 to ship it USPS in 3 days to Kalaheo, Hawaii. Not bad :)

|

|