|

|

|

|

|

|

The front is IFS....so it's a 7.5" ring gear but don't under-estimate the over-all strength of this carrier based on ring size. All the bearings are very similar in part number plus the way these carrier bearings are "captured" is better for fighting ring deflections. |

|

These Motives are from Italy (India for the set that went into the rear). The factory laps them in and runs a load bearing pattern with this reddish paint. A nice QC step. |

|

The front Truetrac is well made. 3 bolts on each side holding the end-caps on. |

|

Motive master kit. |

|

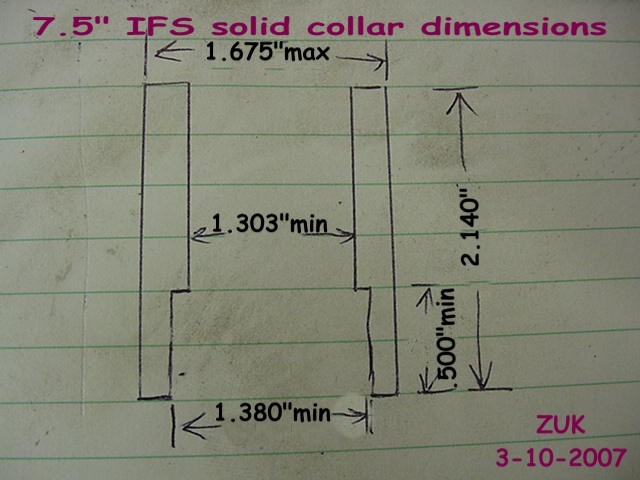

The "custom made solid collar" made by the owner of the truck. This collar has very simple dimensions

and is easy to make on a lathe.

|

|

ID on the top end is 1.303 minimum

|

|

This is the rough draft that I made up for the machine shop. |

|

These bearing caps have to go back on the same way....both caps are uniquely marked like this. |

|

Using the 10 ton Harbor freight press to recover the pinion shim... |

|

Some of the rings are very tight. No boiling water needed here...persuasion is a powerful tool. |

|

The Motive master kits have the better 10.9 grade bolts in them. |

|

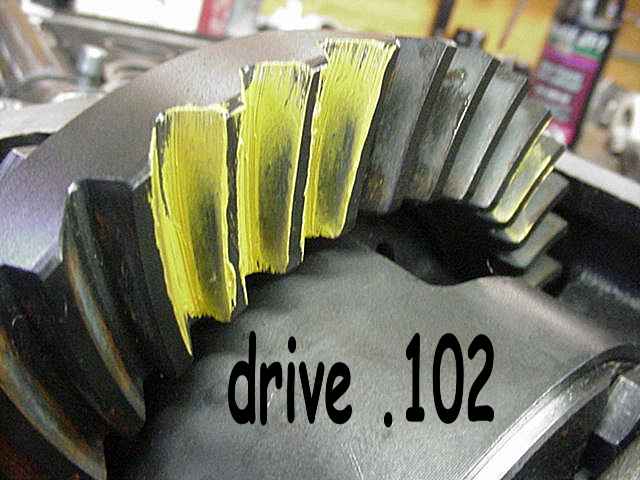

...pressing the bearing on with the factory .102" pinion shim. |

|

...pressing both carrier bearings on at the same time. Beware-sometimes due to over-lapping lips, the carrier bearings do not get pressed on those last 5 or 6 thousands....that could raise hell after the first 10 miles on the road with sloppy bearings. |

|

I started with .046" for shims...on the fourth try with .040", I had a nice 15 in/lb of pinion pre-load. Solid collars can be more "time consumming" but they also do not fatigue and loosen up like thin crush sleeves can. |

|

New inner and outer races are tapped in...

|

|

This 35 dollar beam-type torque wrench from Park tools is a must for measuring pinion pre-load. |

|

Upon installing the case into the carrier, I noted a large gap even with the carrier bearing washers in place. Turns out the bearings supplied with the master kit have a thinner race. The new bearing is on the left and the old one is on the right. |

|

The old one on the right is much taller than the new one. |

|

I measured about 90 thou between the two... |

|

I found some shims that would work... |

|

...and re-pressed the new bearings on with 90 thou behind each bearing |

|

Looks like the drive side could stand to be just a little deeper. |

|

The front gears use the coast side most of the time....not bad... |

|

Complete teardown and added 3.5 thou more. About the same. |

|

Coast looks good. |

|

New axle seals were installed |

|

The pinion nut supplied in the Motive kit is the best I've EVER seen. A tall steel nut with a large thread count...not like the aluminum-like versions supplied with most others. |

|

Done. ZUK |

|