|

|

|

|

|

|

Mike is in the process of building up his 1982 truck. It came to me with a 488 Richmond "double diamond" logo which dates the install back in the 1990's sometime. The backlash was excessive at .016" and the CBPL was sloppy. The plan is to put in a new Precision 488 with cryo treated bearings and a solid collar...also, add an Aussie. |

|

The case is removed and stripped of the Richmond ring and the old carrier bearings. The Aussie is first to go in. The pin is tapped out in the photo. |

|

Almost every 4 cylinder Aussie that I've installed requires 30 seconds of filing with the course rat tail file in order to get the clutch drivers in place. |

|

It will be partially assembled to check tolerances... |

|

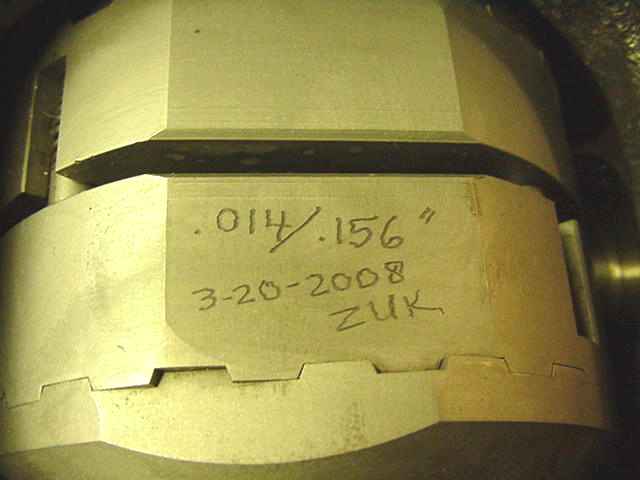

Worst case I found was .014"....the spec is .006~.020" |

|

The springs went in extra easy this time....I think Aussie shaved off 2 thou or so on the slotted tunnels to allow the springs to slip in nice. |

|

The pin is tapped back in, hole pinched down, and done. |

|

The distance between the drivers was well within spec. |

|

Probably a good idea to scribe the measured values on the unit. |

|

The new cryo bearings were not as tight a fit as I wanted so I used Sleeve Retainer by Loctite. |

|

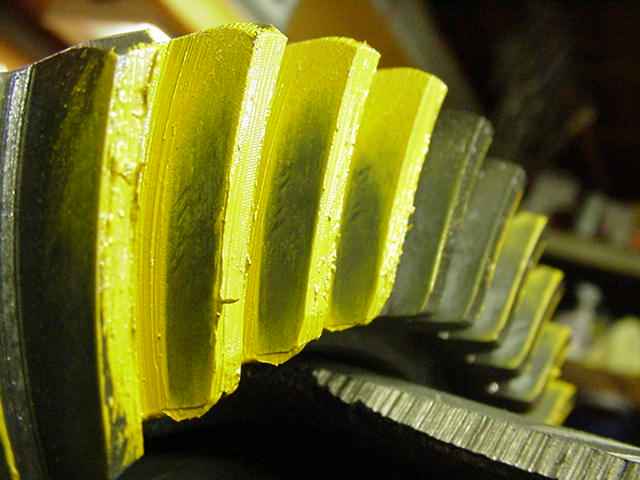

The precision ring is slipped on and the bolts are torqued to 75 ft/lb with red Loctite. |

|

The pinion is installed without the solid collar for a pattern check. |

|

These are the not so typical markings that I noticed on the Precision ring. |

|

... |

|

Using a pinion shim of .101" with a backlash of .010", the pattern is still a bit shallow. |

|

Coast looks ok though. |

|

So I tore it back down and added .004" to the depth (.105" total) and this is very good. |

|

Coast. |

|

Pinion says it's ok also. |

|

Now with the pinion depth established, it's time to install the solid collar. Using a solid collar shim of .066" resulted in about 12 in/lb of PPL. If I tighten the pinion nut extra tight I can squeeze a few more inch/pounds of pre-load which is what I did in the end. This is probably due to the soft shims actually crush a little more when the nut is cranked. The thicker the shim pack the more crush that can happen. |

|

A new seal is installed. The pinion flange is slipped on and the nut is Loctited in place. |

|

Turning my attention to the other side of the 3rd, anti-seize is liberally splashed on and the spanner rings and bearing caps are installed. |

|

With lots of hammer hits and careful adjustments to each side, I was able to dial in 150 ft/lbs of CBPL and guide the desired backlash value in place. |

|

Final average BL was .0095" |

|

Markings found on this 488 Precision boxed gearset. |

|

Done. :) |

|

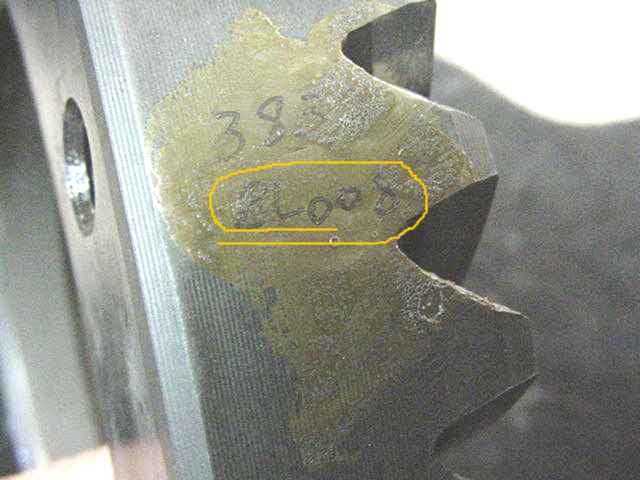

Here's a few pics the the beat up Richmond gear that I took out.... |

|

BL=.008 |

|

... |

|

The ring teeth were scarred pretty good. Oil starvation can cause that. |

|

I re-used all of the packing materials that Michael sent to me. Rolling and taping the cardboard like that was an interesting solution. |

|

Back to Michael in Justin, Texas. |

|