|

Steve from Toronto Canada gets 3.73 gears installed with a FLIPPED Truetrac

|

|

(75 BIG pics loading)

|

|

NOV 28 2016

|

|

|

Steve from Canada has an 84 Celica Supra that has been plagued with driveline

backlash, clunks, severe whining (they all seem to he believes) and vibration during

his 12 years of ownership. The plan is get a good some good 3.73 take-offs from

JustDifferentials.com and combine that with a True trac.

|

|

|

|

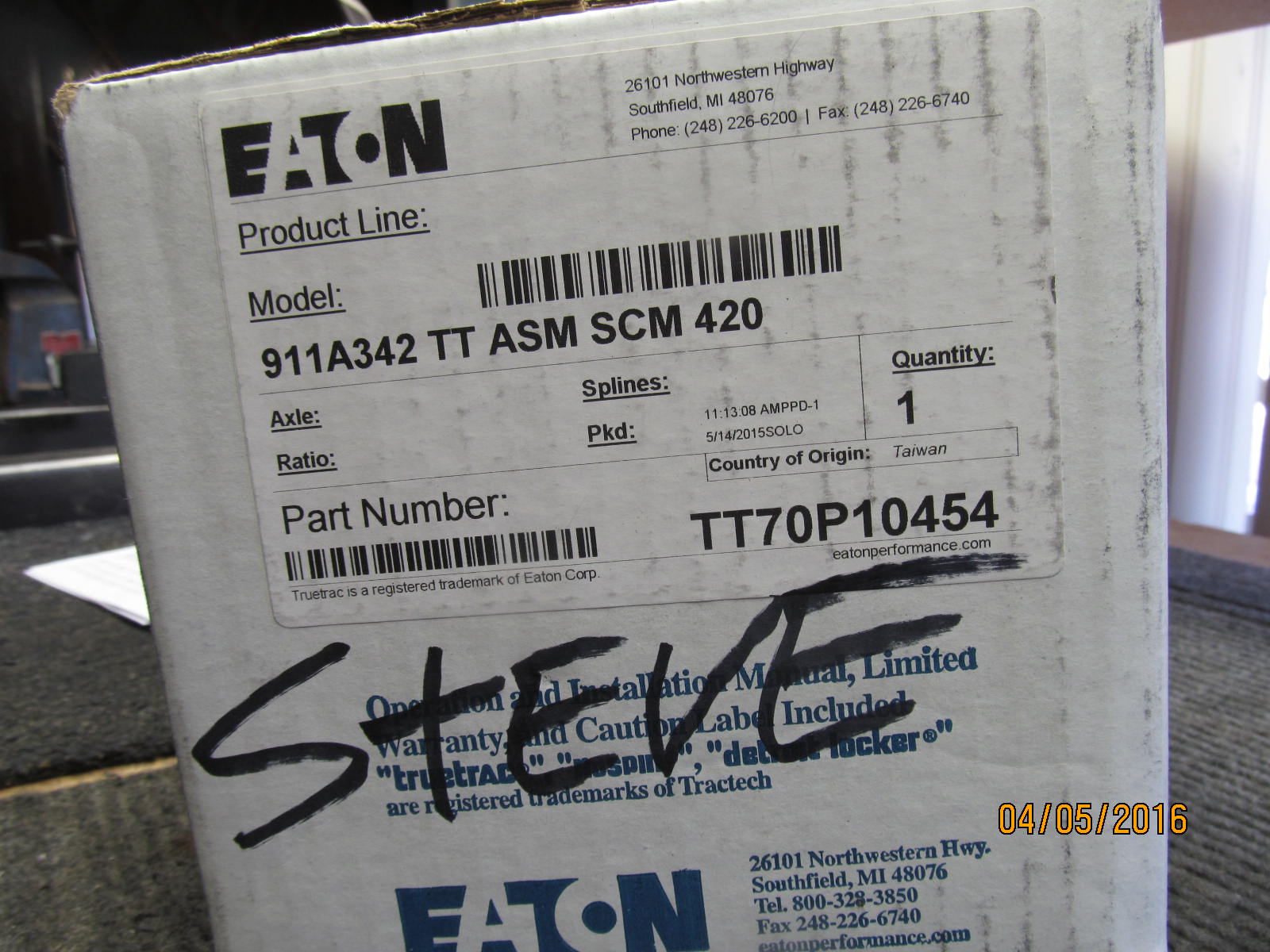

The 911A342 is an old number and was designed for the 7.5" IFS front ends. The new superceded

number is 911A644....same part but different part number. That new number was

what was actually engraved on the True Trac unit inside this box.

|

|

|

|

|

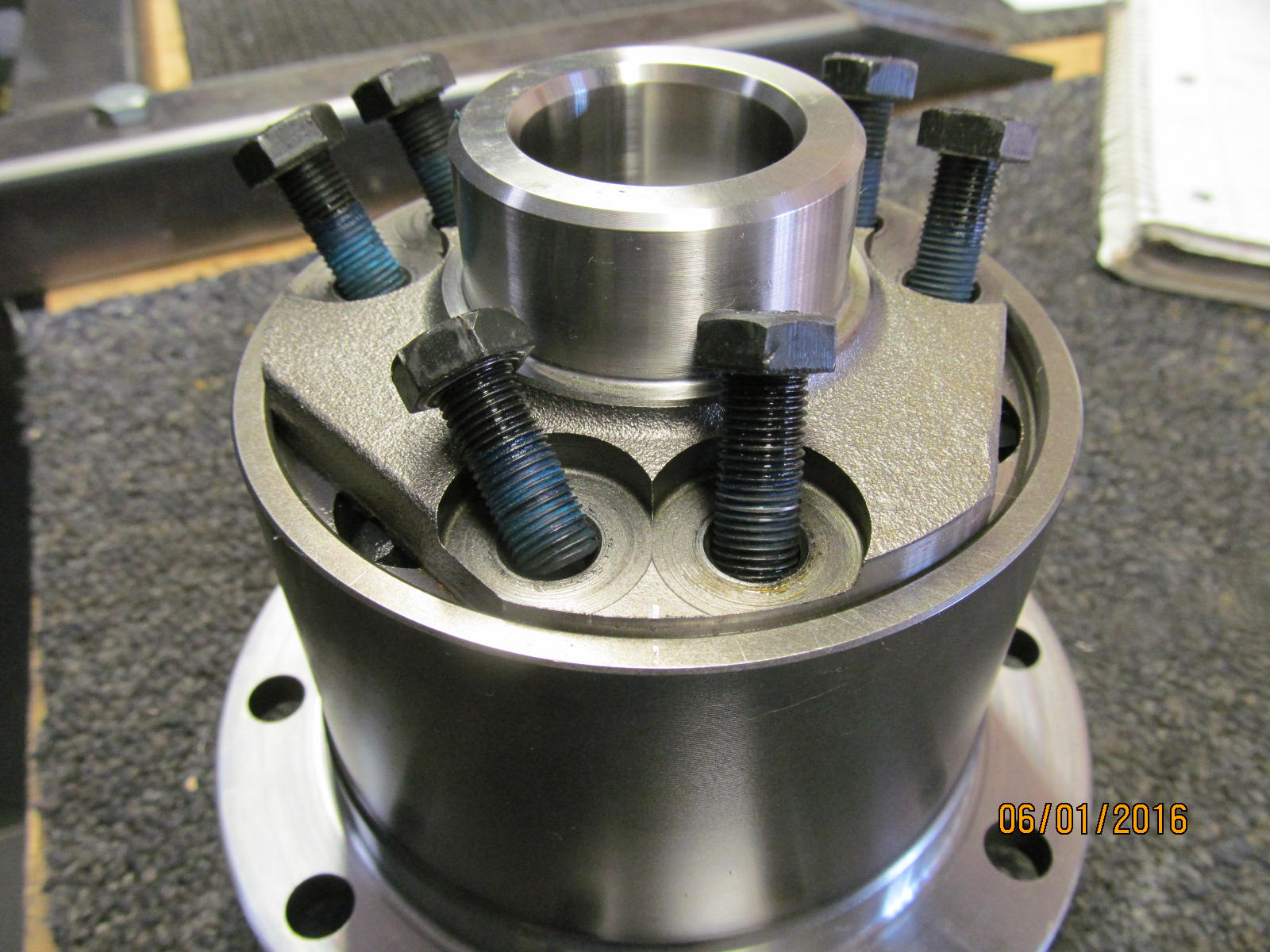

New Yukon 23 spline flange.

|

|

|

|

|

Nice quality.

|

|

|

|

|

....................

|

|

|

|

All the parts were kept organized on the shelf until everything came in.

The 3rd was kinda rusty and grundgy.

|

|

|

|

|

Teardown begins. Remove the stub shafts.

|

|

|

|

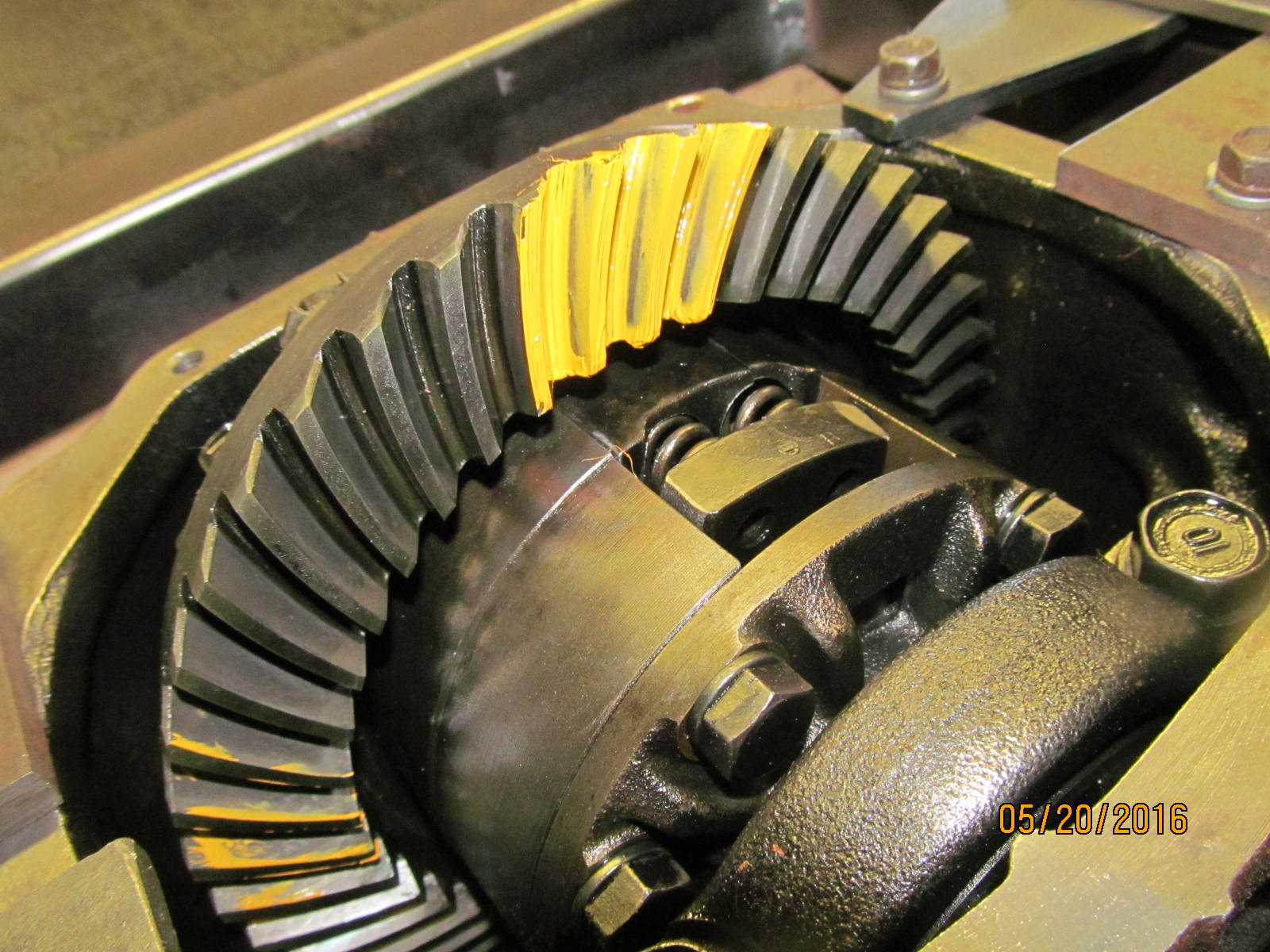

These 430 gears I painted them and they have a decent paint. The 430's and the LSD are going bye-bye

and 373's with a True trac will be replacing them.

|

|

|

|

|

..............................

|

|

|

|

|

.....................

|

|

|

|

|

..................

|

|

|

|

|

The 2 caps are marked and removed.

|

|

|

|

|

The 2 washer plates are documented.

|

|

|

|

|

Removed the pinion.

|

|

|

|

|

It was decided to have a beadblasting ......

|

|

|

|

I took the 3 pieces down to NextGen Precision Manufacturing (used to be called Tom Yancer Racing)

and had them do a nice beadblast. Much better than before.

|

|

|

|

|

911A342 on the outside of the box.....

|

|

|

|

....911A644 on the inside. Made is Taiwan and I can't see a thing wrong with the machine work.

I like it as a matter of fact.

|

|

|

|

|

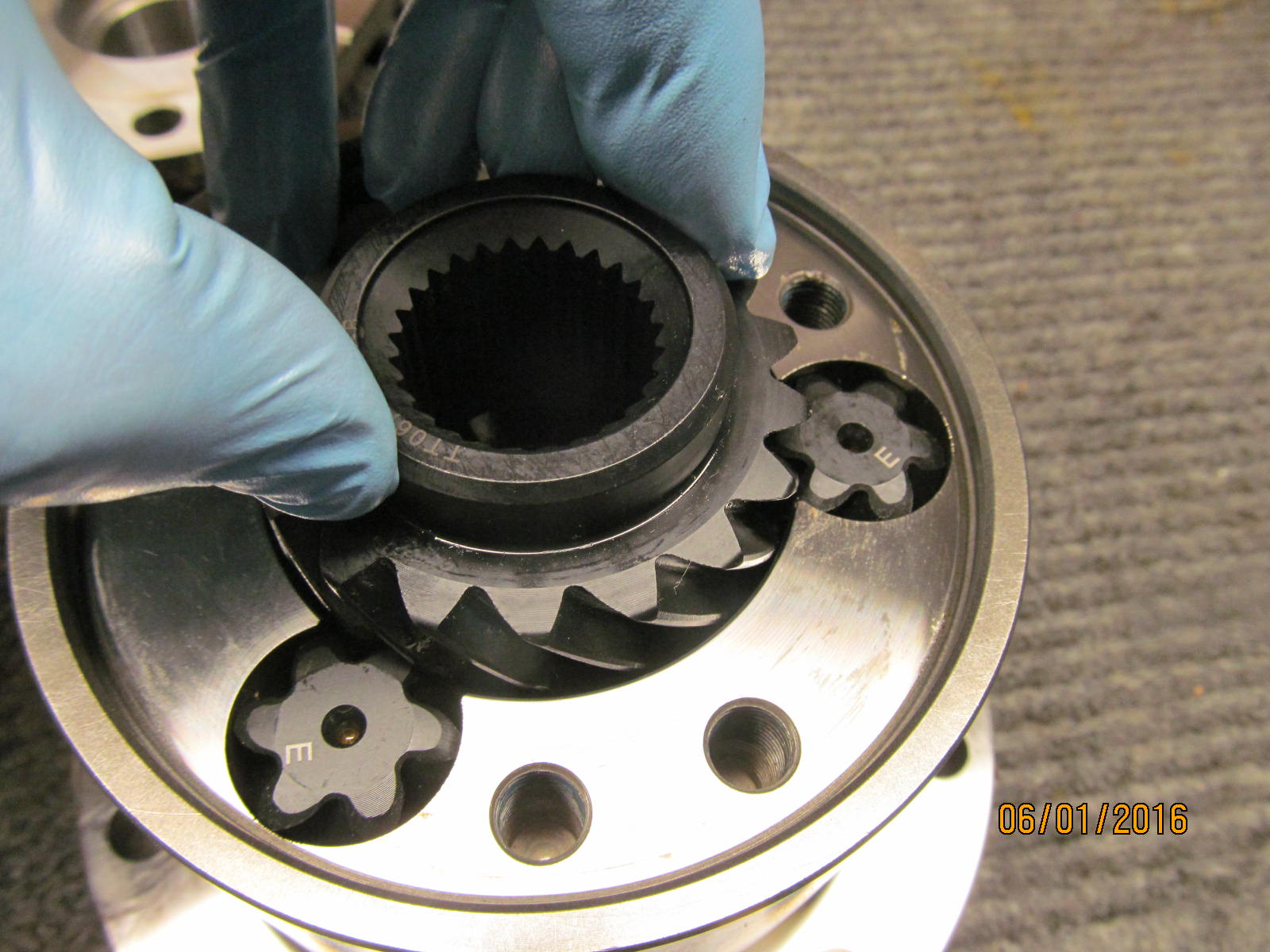

Take the 6 bolts off the front side.

|

|

|

|

|

.....................

|

|

|

|

|

This gear set will go on the backside. Notice the center gear swirls counter-clockwise.

|

|

|

|

|

The backside.....

|

|

|

|

|

.....................

|

|

|

|

|

Notice these swirl clockwise. These will swap over to the other side.

|

|

|

|

|

.............................

|

|

|

|

|

...............................

|

|

|

|

So, the gears from the other side that swirled clockwise now move over to the front side.

The Rule of Thumb....if the front side center gear swirls CW then they are for the rear end application.

|

|

|

|

|

The remaining set goes in the backside....they swirl CCW.

|

|

|

|

|

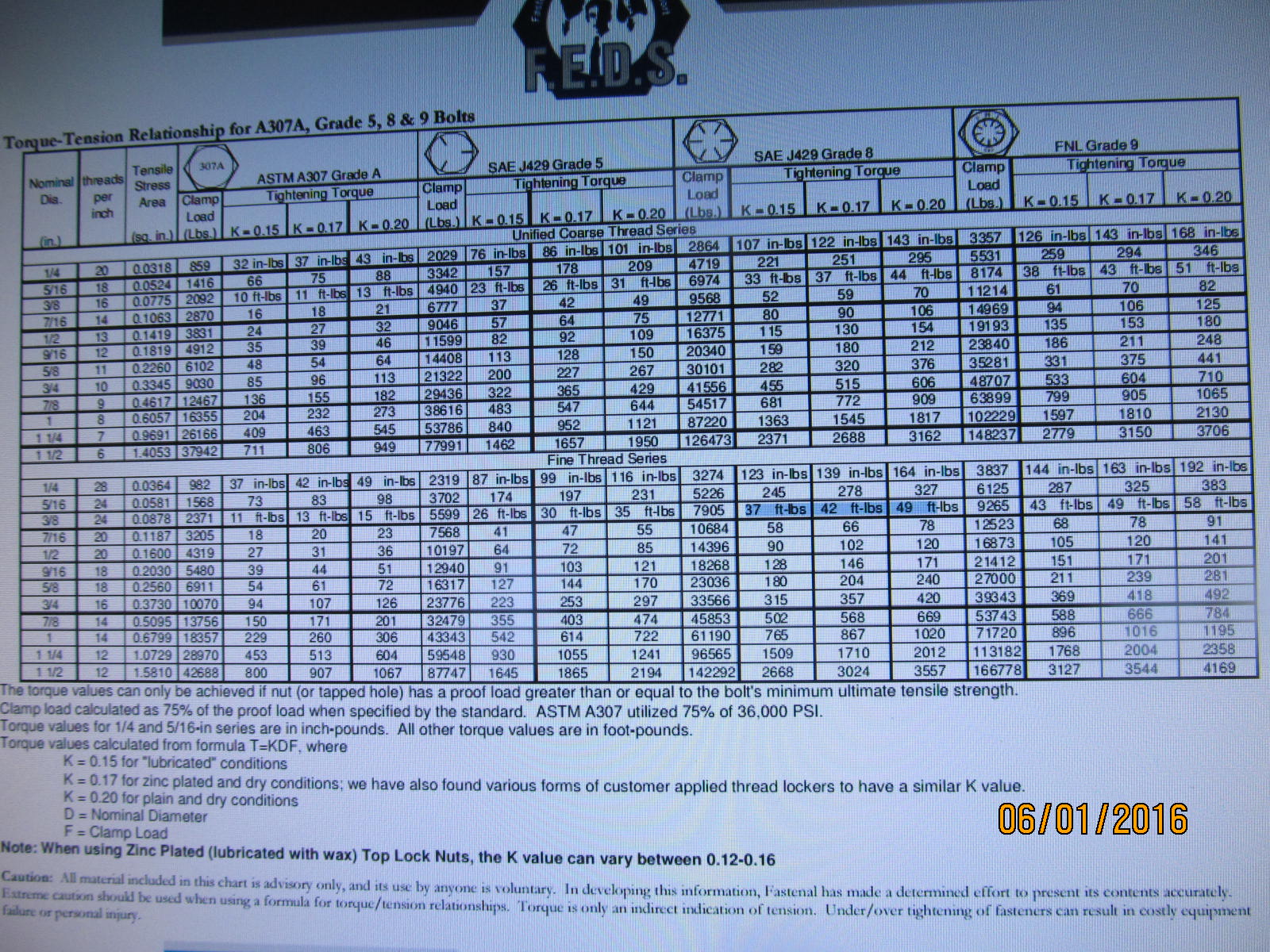

I googled it and seems like 45 ft/lb was the torque to use on these 12 grade 8 bolts.

|

|

|

|

|

A touch of red Loctite.

|

|

|

|

|

Over to the front side.....place the gears in the hole.....

|

|

|

|

|

Then tighten all 12 bolts to 45 ft/lbs.

|

|

|

|

|

......................

|

|

|

|

|

And this Truetrac is now ready for the rear.

|

|

|

|

|

--------------------

|

|

|

|

Solid collar......Genuine Toyota bearing part numbers.

These parts can be purchased directly from Weir Performance.

|

|

|

|

|

Axle stub seals and a pinion seal.

|

|

|

|

|

Tapping the races in with gentle persuasion.

|

|

|

|

|

Inner race is fully seated.

|

|

|

|

|

....................

|

|

|

|

|

Outer race is verified fully seated down.

|

|

|

|

|

This shell looks a lot better than it used to look.....that bead blasting was well worth it.

|

|

|

|

|

.0985" pinion shim is pressed on with the new pinion bearing.

|

|

|

|

|

--------------------

|

|

|

|

|

A quick file check and no rough spots found.

|

|

|

|

|

.......................

|

|

|

|

|

....................

|

|

|

|

|

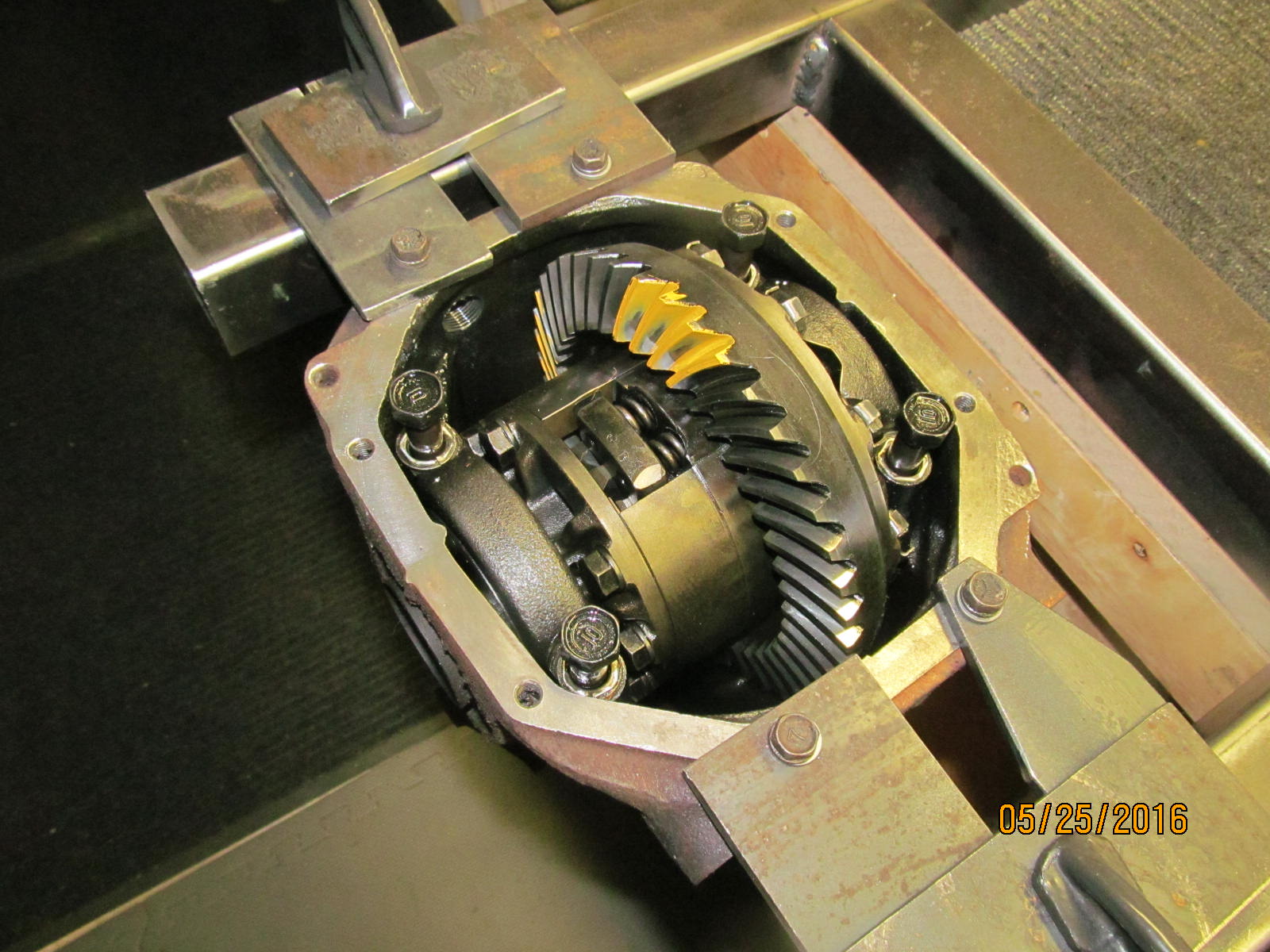

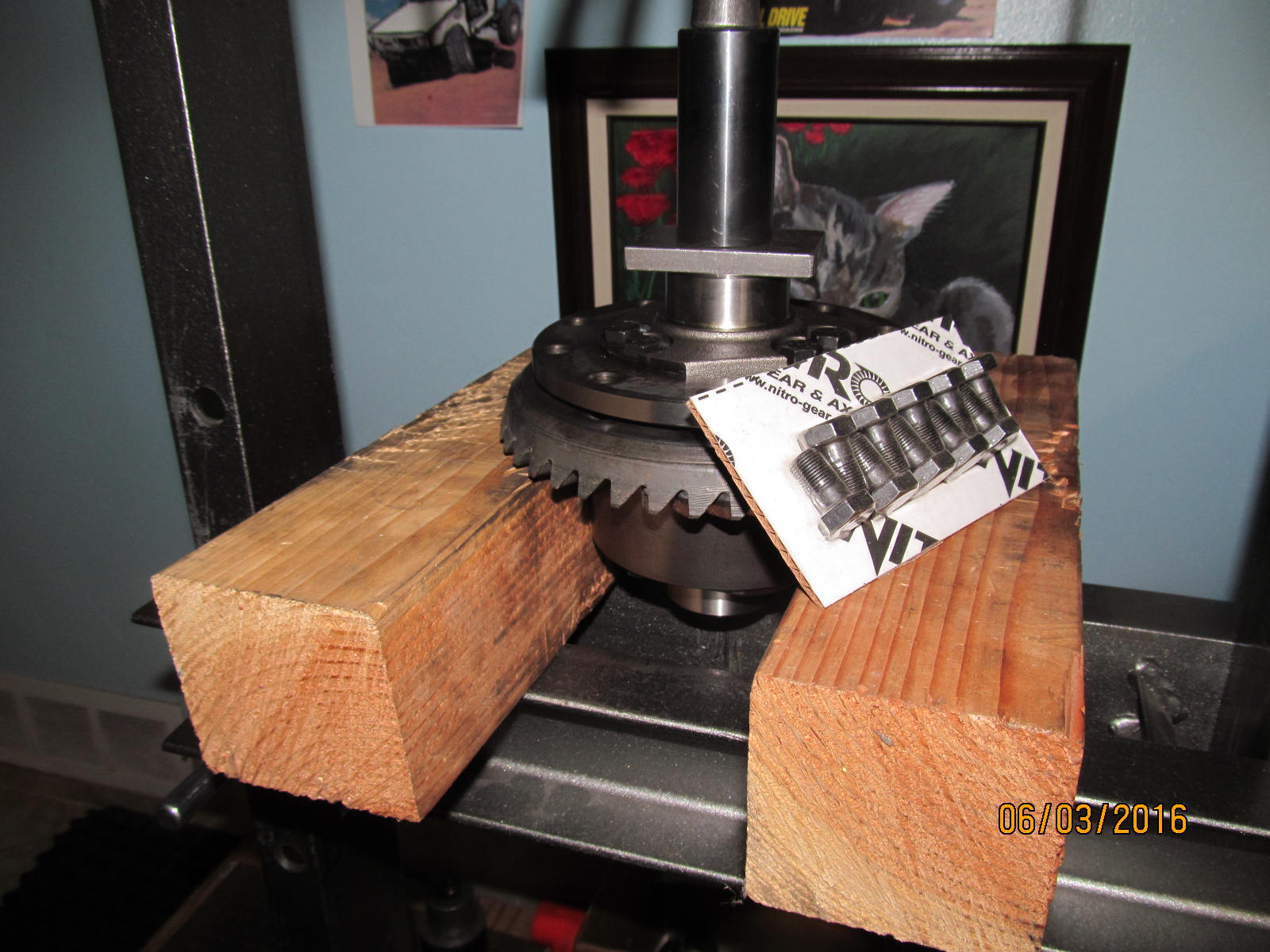

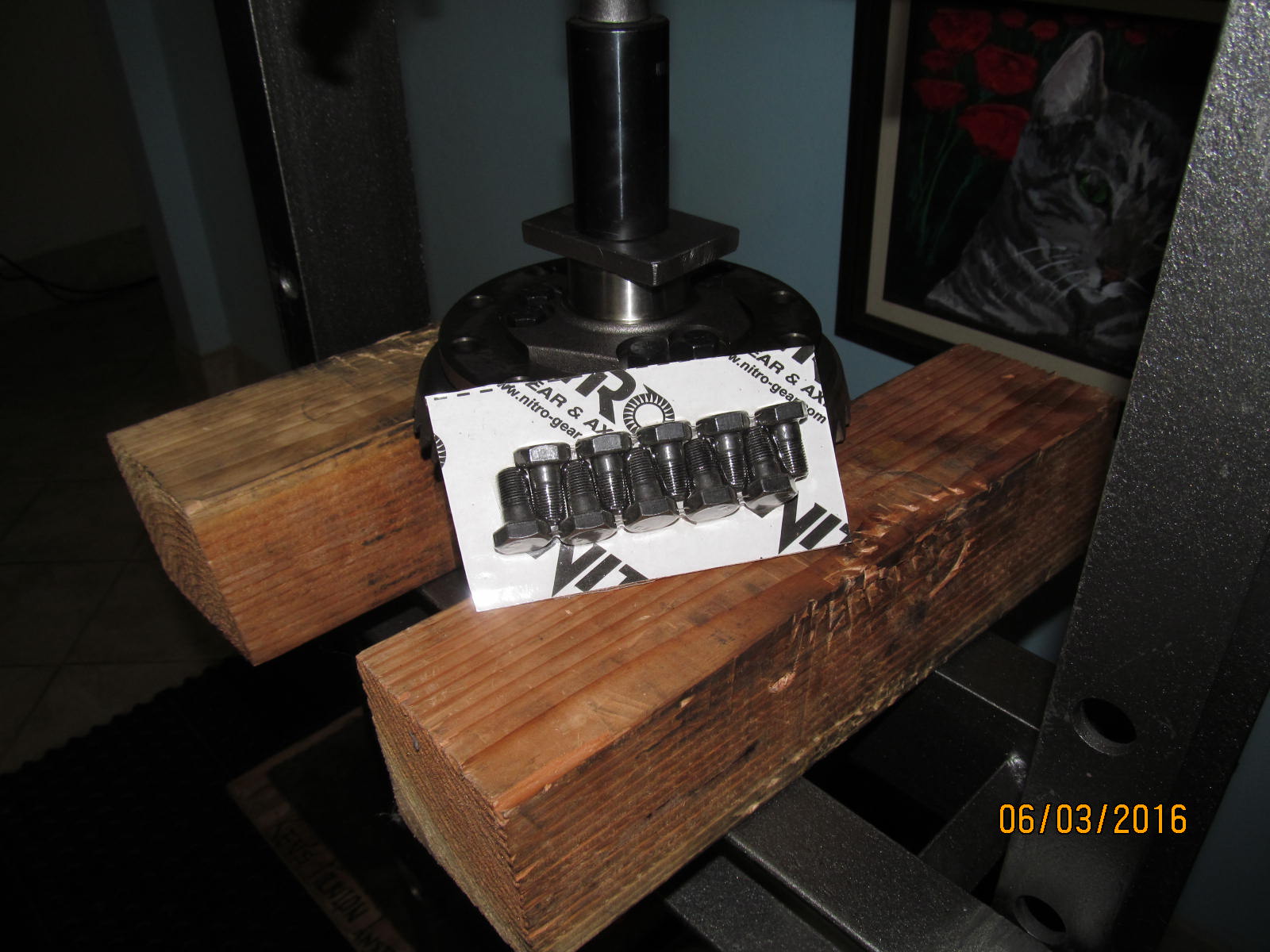

Ring gear is pressed on the tight fitting True Trac. The bolts can make sure it stays lined up with the bolt holes.

|

|

|

|

|

.........................

|

|

|

|

|

70 ft/lbs and red loctite on the 10 ring gear bolts.

|

|

|

|

|

New carrier bearings are pressed on.

|

|

|

|

|

This portion is complete.

|

|

|

|

|

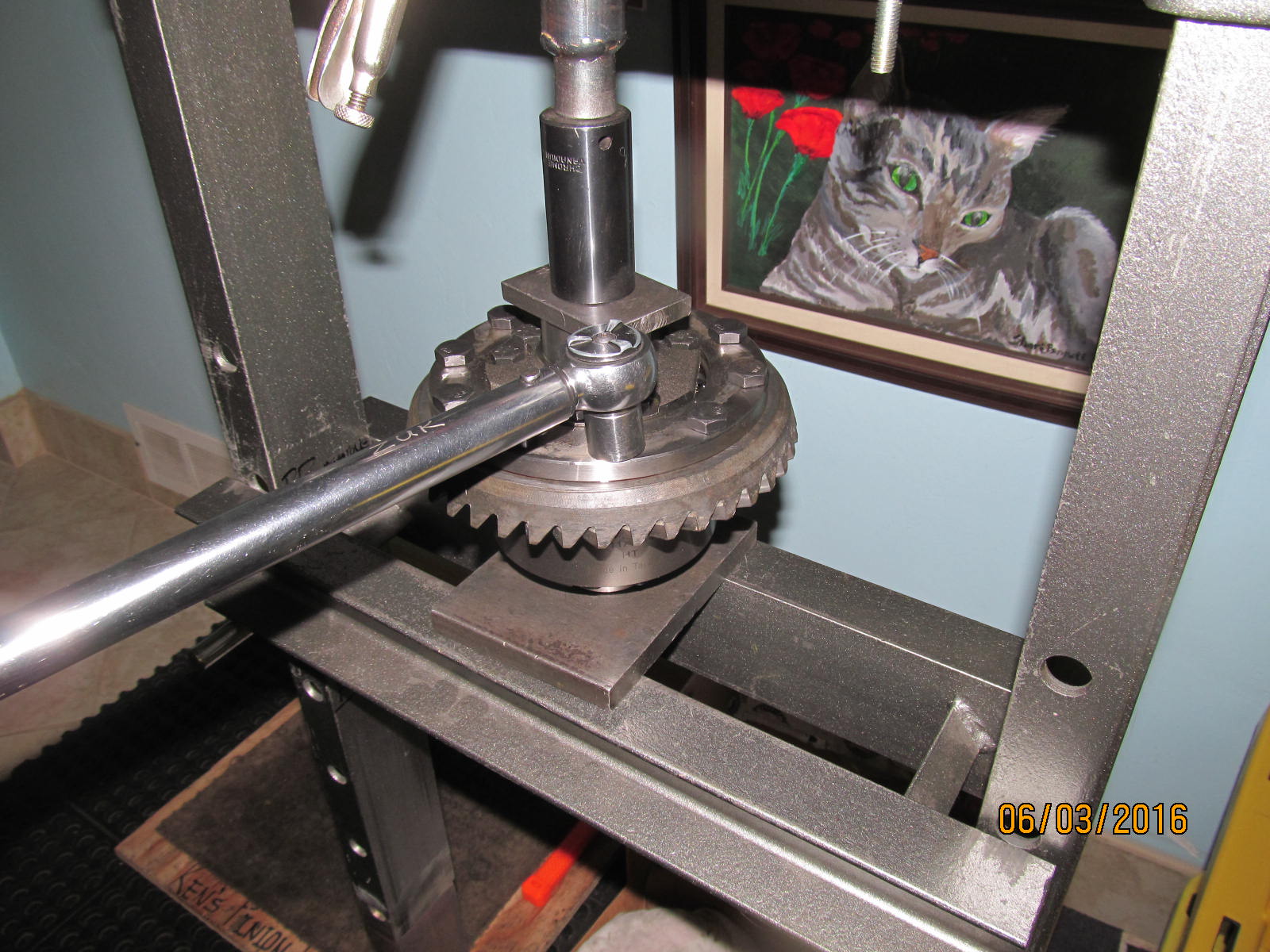

The pinion and shop flange are loaded up in the differential case.

|

|

|

|

|

Washer plates in front of the bearing or shims behind the bearing are both aok. Using shims here.

|

|

|

|

|

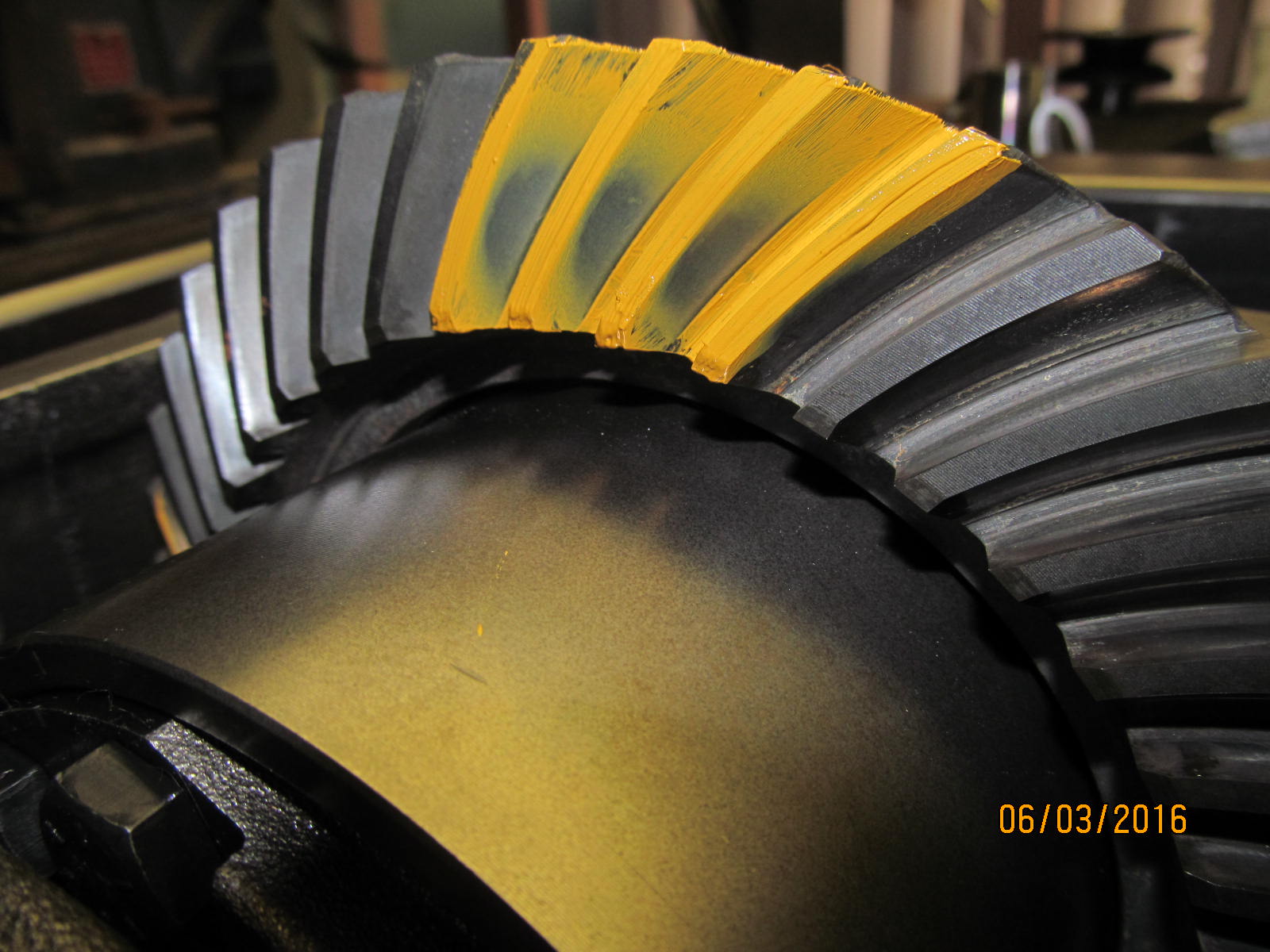

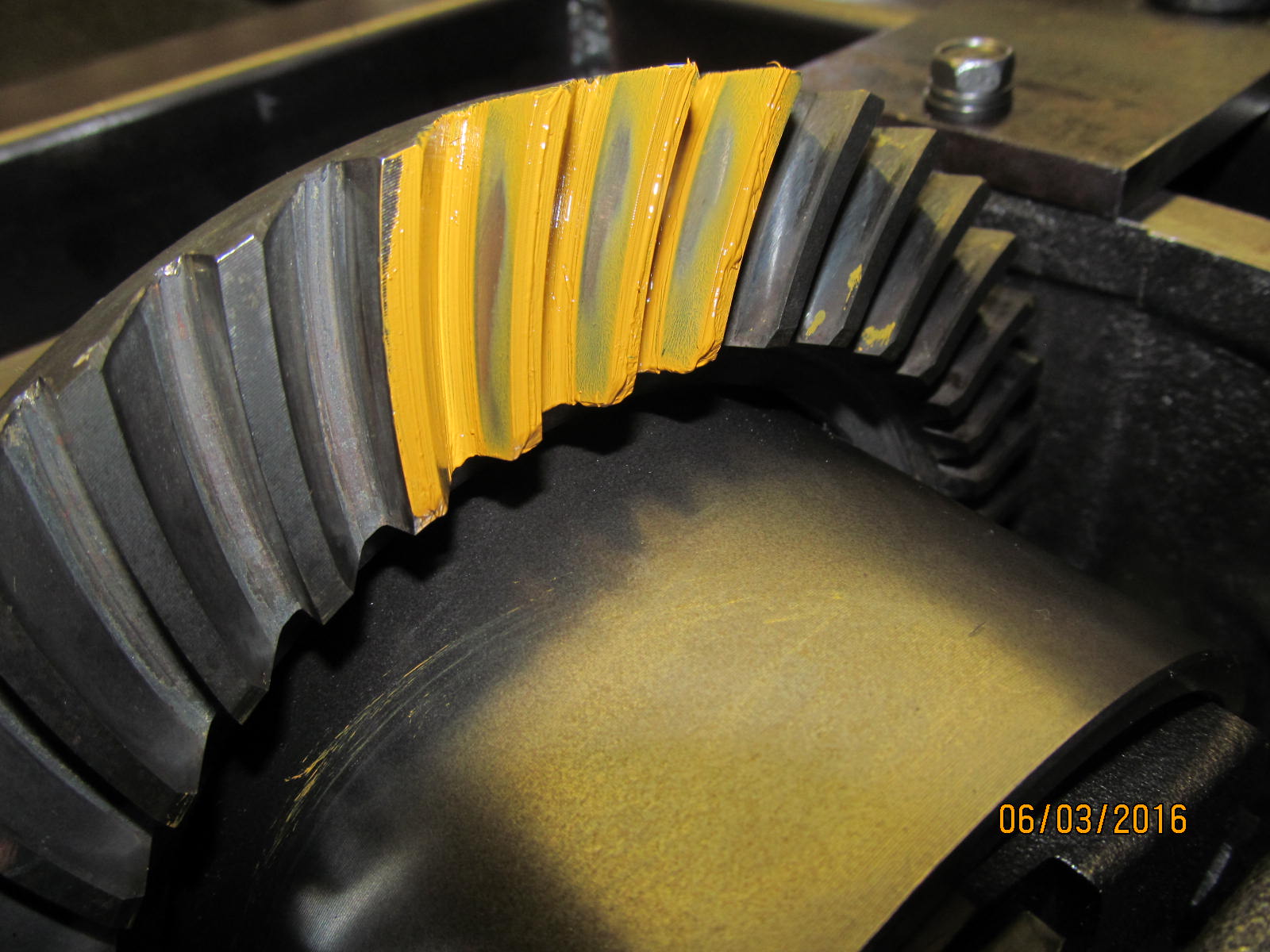

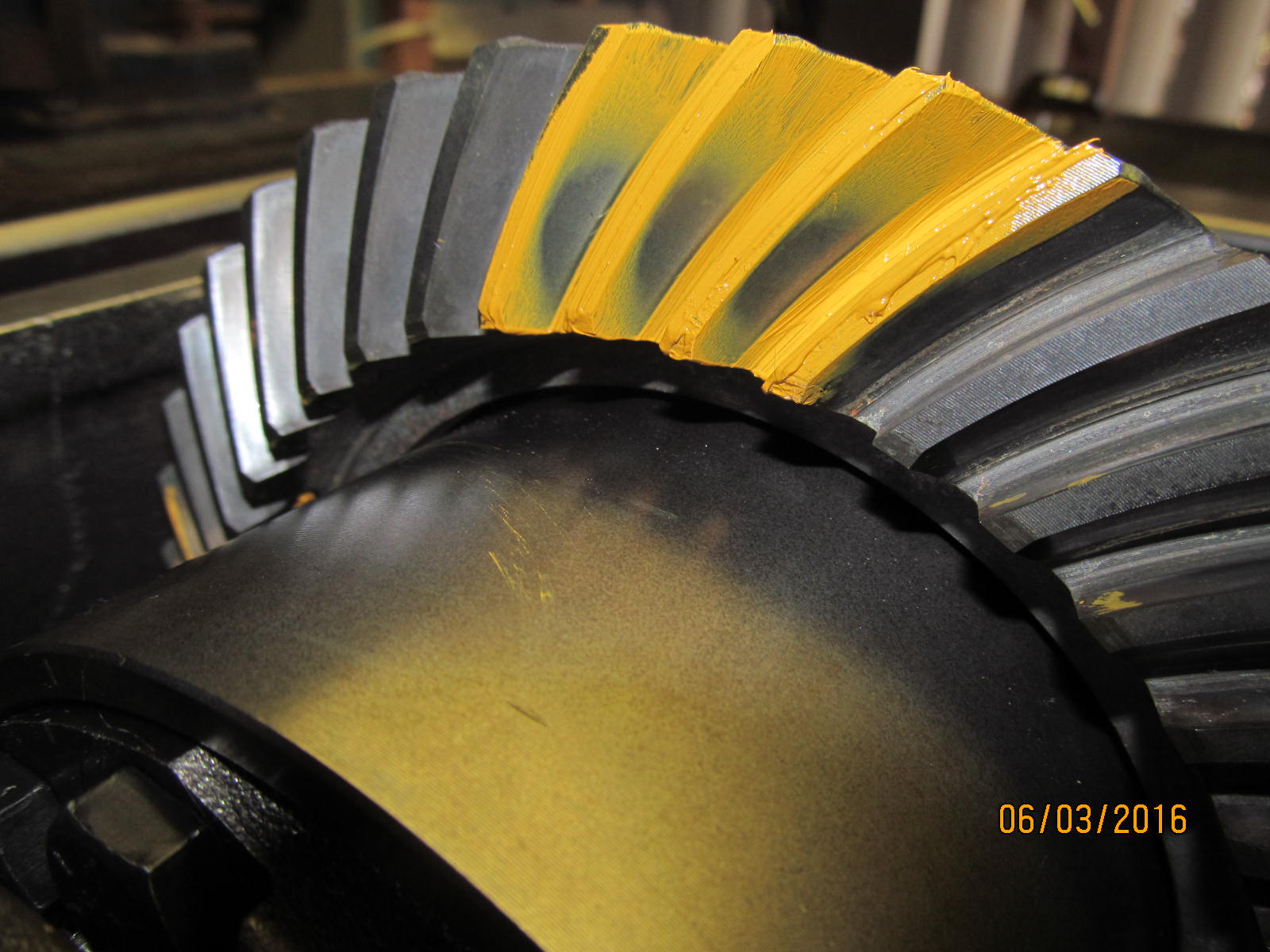

Drive side pattern.....not bad.

|

|

|

|

|

Coast.....shows us that we really do have the right depth.

|

|

|

|

|

Drive side on the pinion tooth.

|

|

|

|

The original old crush sleeve measured at 2.165 so that means the solid collar is gonna be an overall length

of 2.165" plus a couple of thou more for the new bearings. Turns out 2.169" was the magic number.

|

|

|

|

|

With the solid collar in place , now the seal is installed.

|

|

|

|

|

Now the new 23 spline flange.

|

|

|

|

|

With the pinion nut tightened up to 150 ft/lb, the resultant Pinion Pre-Load checked in at a nice 8 inch/pounds.

|

|

|

|

|

DING!! and done on this end.

|

|

|

|

|

Best guess on the new washer plates.

|

|

|

|

|

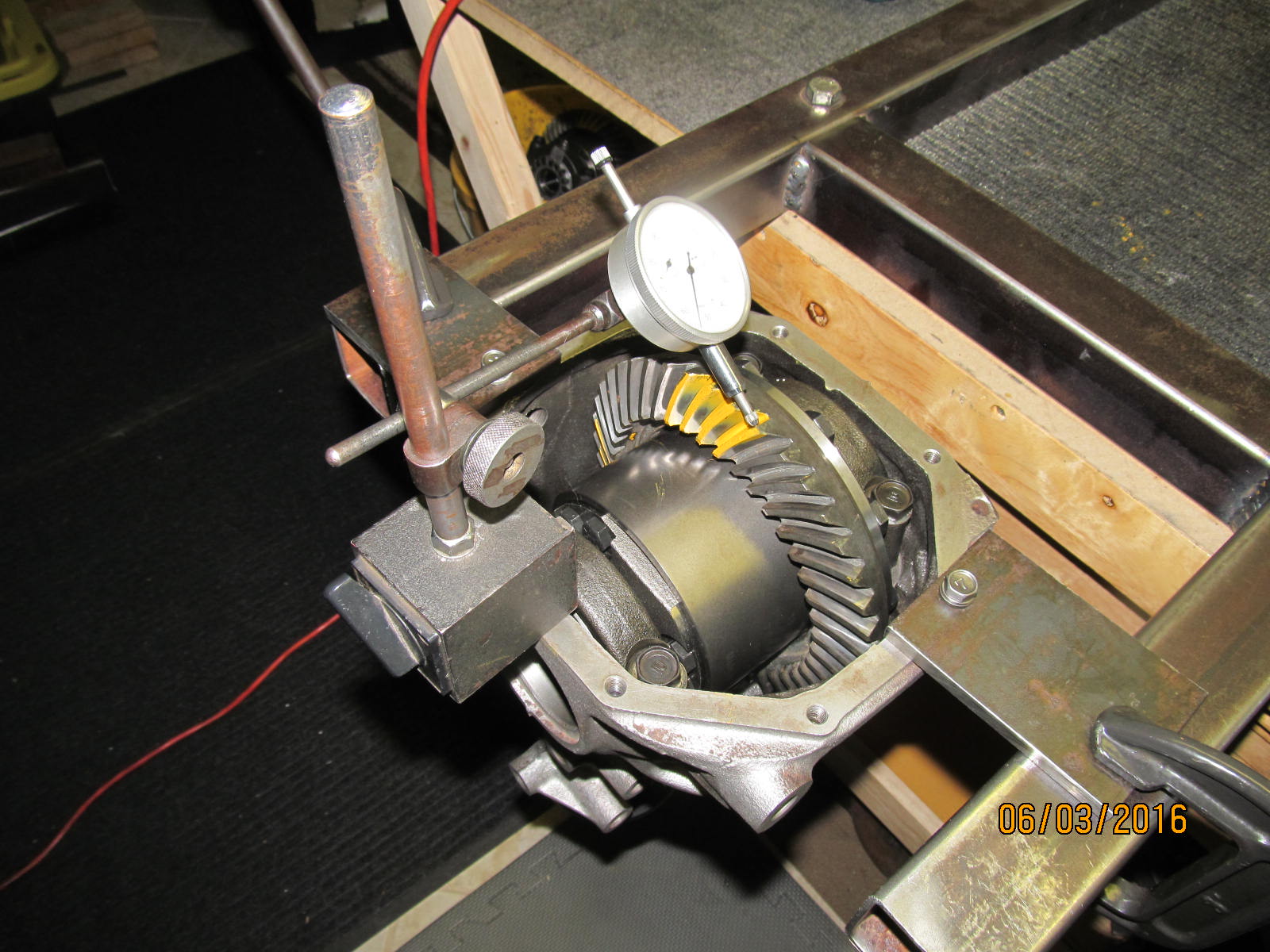

Not bad.....backlash measuring around .007".

|

|

|

|

|

Total bearing preload measuring at 15 inch/pounds.

|

|

|

|

|

Bearing caps tightened to 70 ft/lbs.

|

|

|

|

|

Final paint check....drive side.

|

|

|

|

|

Coast side say it all. Says the depth is correct.

|

|

|

|

|

Ready to go back to Steve.

|

|

|

|

|

...........................

|

|

|

|

|

............................

|

|

|

|

|

.............................

|

|

|

|

|

............................

|

|

|

|

|

Ring gear is inscribed with a dremel drill.

|

|

|

|

|

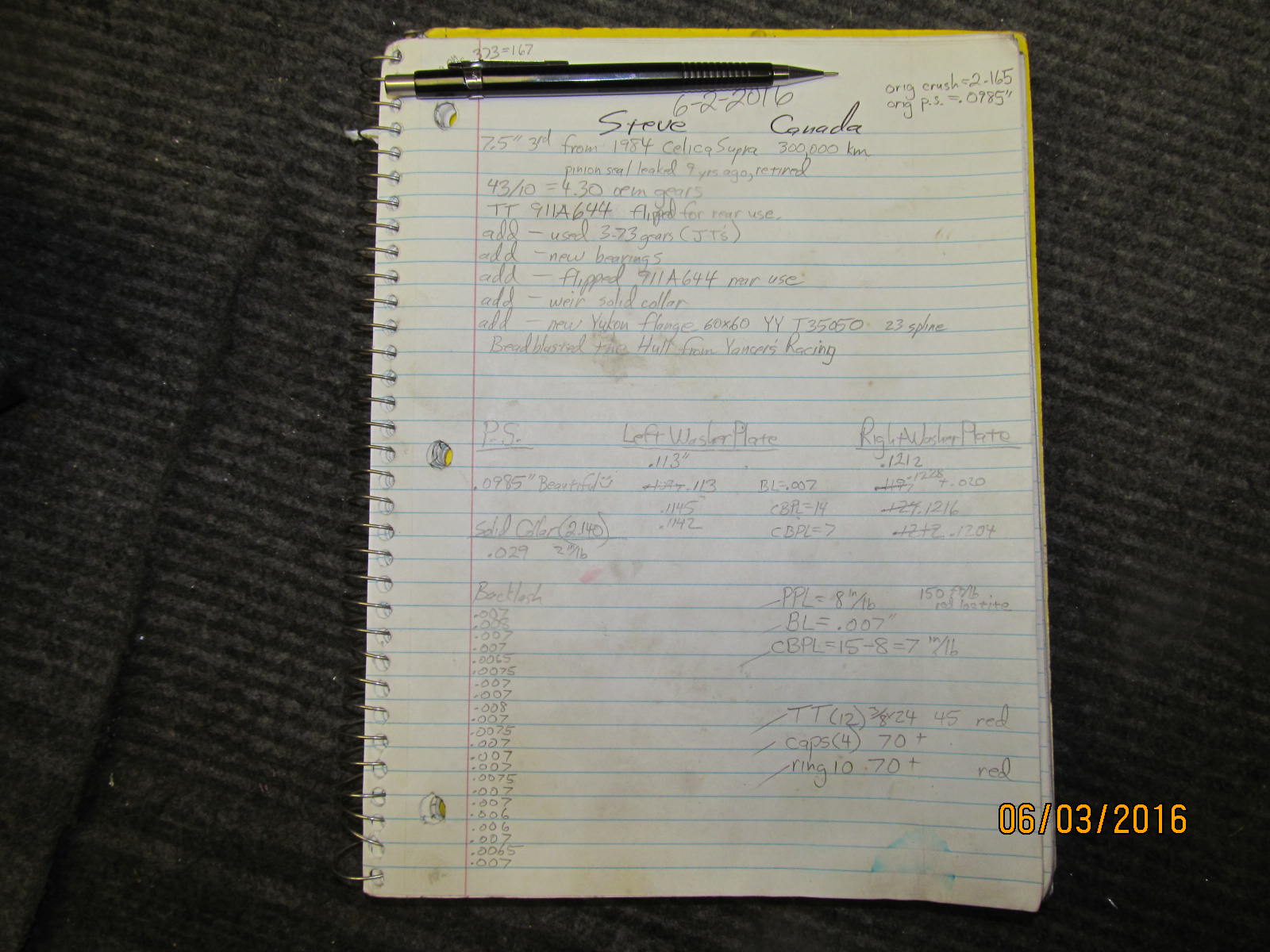

The standard snapshot of the gear install info.

|

|

|

|

|