|

|

|

|

|

|

Rob from Warner Robins, Georgia normally has his diffs done by a local gear guy in his 80's. Unfortunately, he passed away about 6 months ago. The other guy that Rob trusts picked up something the wrong way and now is layed up with a bad back. So that left Billy Ray to install the 488 Yukon gears and a Supra LSD into his V6 3rd. Upon getting it back from Billy, Rob just did not feel good about that install so, after talking to me, sent the diff my way for a health check. |

|

The ring gear only had 2 markings on it. #177 as shown above...... |

|

...and this here. I think this is a Richmond gear based on what I've seen in the past. |

|

You can't see it but I sure can...the pinion had about .080" of vertical movement as pictured above. The pinion nut was tight, too. Somebody didn't do a very good job crushing the crush sleeve. |

|

Everything felt so sloppy that there really wasn't much of a reason to do a pattern check but I did anyways. Sure is riding the face (top) of the tooth. Yep, that's what I found on the pinion.... only .040" shimming. That might be ok for a Dana.... |

|

Used carrier bearings were on both sides of the case. Rob paid for a new master kit to be installed but I didn't see much of it in there. These carrier bearings were very tight and took a good pull from my specialty puller OTC 4520 puller |

|

The previous installer re-used the 50KB8301 Supra bearing which is ok if in good condition.....but it was mated up to the "skinny truck race" (LM104912) for unknown reasons. |

|

Upon removal of the pinion, I noted that the inner and outer bearings were both NEW.... but both races were the OLD ones. Note the pitted condition of the outer race. |

|

.040" worth of shims was all I found behind the pinion head. Should be around .075". |

|

New pinion bearings will go back in. |

|

With the right tools the new races will go in with little trouble. |

|

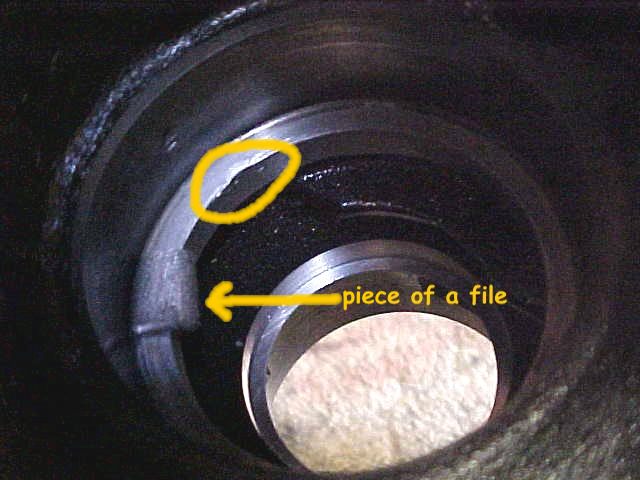

In the process of removing the used big race, I nicked the mounting surface a little which is common. Using that sliver of a file chunk as shown in the pic, I am able to restore the surface flatness. |

|

With the pinion back in the housing with new bearings and races....a solid collar with .059" shim and the pinion nut tightened with the electric impact, I measured the PPL at 5 in/lb. This is the value I shoot for with new bearings because I know that when I do the final tightening phase with the 4 foot cheater bar that "things" compress a little more and the PPL sneaks up to 10 in/lb final value. |

|

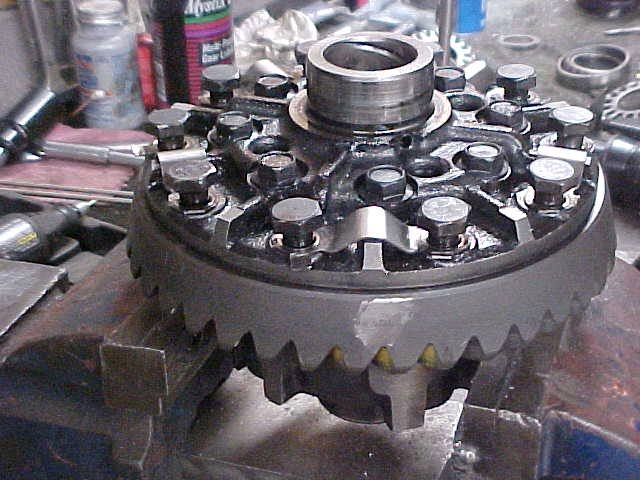

The ring gear is removed and inspected. The re-used metal tabs go in the garbage. I will clean the ring gear threads and use blue Loctite upon re-assembly. |

|

Remove the case halve bolts.... |

|

...being careful to dis-assemble in order.

|

|

|

|

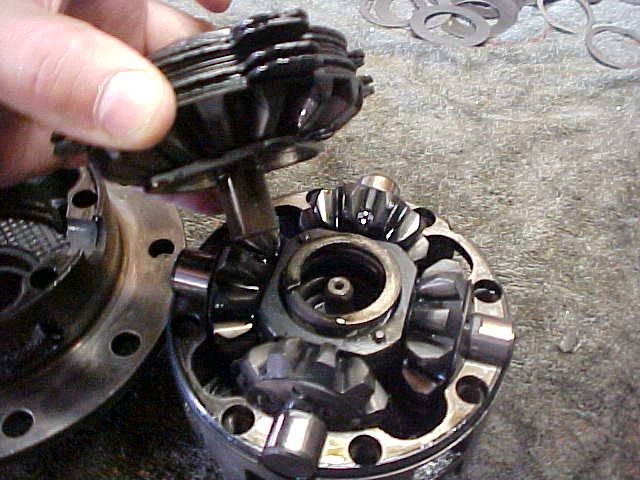

The plates are in very good condition...glad I have this Mavica 75 to take these close up pics ;) |

|

I would think that the packs would be symetrical and alternate the plates.....but this is the order that I saw on both packs. There is one additional plate I left in the case half. |

|

I found the shim of the right dimensions. |

|

|

|

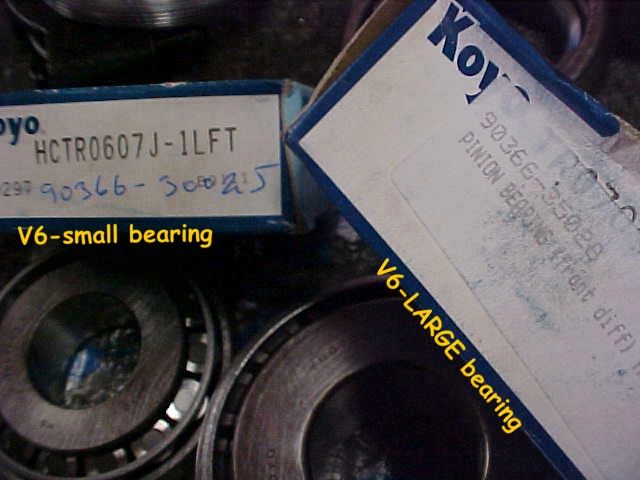

I tried to get the Supra bearing from Napa and Carquest but neither could find a good number ...even from the books. The dealer had no problem looking it up by application. Here's the genuine Toyota part # for anyone doing this. |

|

As shown here, the other side(case side) will get a new 'truck bearing'....Toyota # 90366-50007. |

|

Comparison of the 2 bearings. The Supra bearing is almost a full .100" taller... all of that is due to the race profile. |

|

Installing the carrier bearings... |

|

Lots of anti-sieze helps me get the bearing pre-loads I aim for. |

|

Although it's important to wack the bearing supports while adjusting backlash and carrier bearing pre-load....sometimes it's more important to have some fun with Picture it! 99 :) |

|

My favorite method of developing the pattern is grab with a rag and turn with a wrench. This gives very clear paints. Wow! The hair is going...time to switch shampoos I guess. |

|

The pattern is definately favoring the toe.....but the pinion depth is correct and the backlash is already at 8~9 thou so this is a keeper. This is referred to as a competition pattern. Under high torque loads, the load bearing (pattern) will shift towards the center which is desired. |

|

Coast is nice. |

|

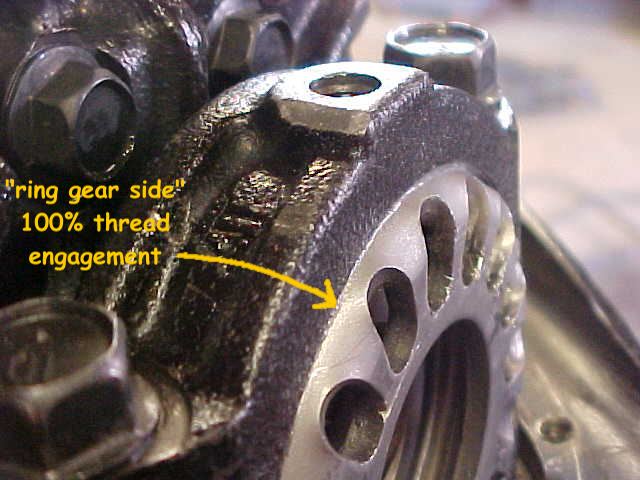

Using the fat Supra bearing/race gives proper thread engagement. |

|

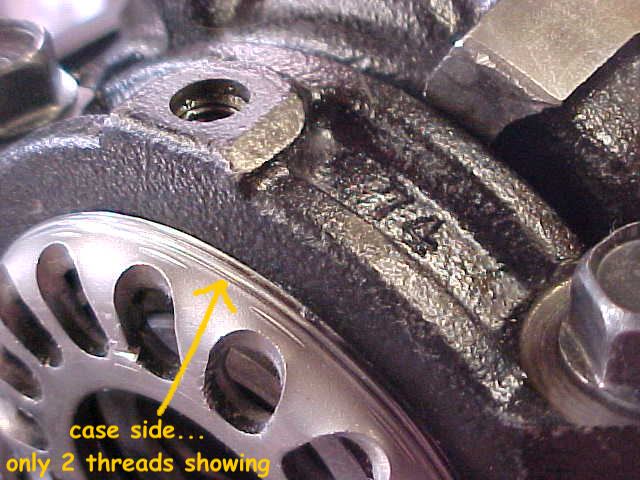

Using the thinner truck bearing minimizes the potential lack of thread issue on the other side. |

|

No allow 65 pound V6 3rd to fall onto smallest finger. Do not click the thumbnail. |

|

Health check is good now though this actually turned out being a full install. Ready to send back to Rob....with the usual certificate. Over and out. |

|