|

Tim Has Terrible Noises After a Local Gear Install

|

|

(55 BIG pics loading)

|

|

AUGUST 19 2016

|

|

|

|

............

|

|

|

|

|

...................

|

|

|

|

|

Fins and Things Trail, Moab

|

|

|

|

Tim is somewhere in Missouri and emailed me about the results of a local gear install from a local shop.

After some email exchanges and a little while later, 2 strong boxes arrived.

|

|

|

|

The front 3rd member is in this box....

The actual front autopsy/rebuild can be followed here..... Front Inspection/rebuild

|

|

|

|

|

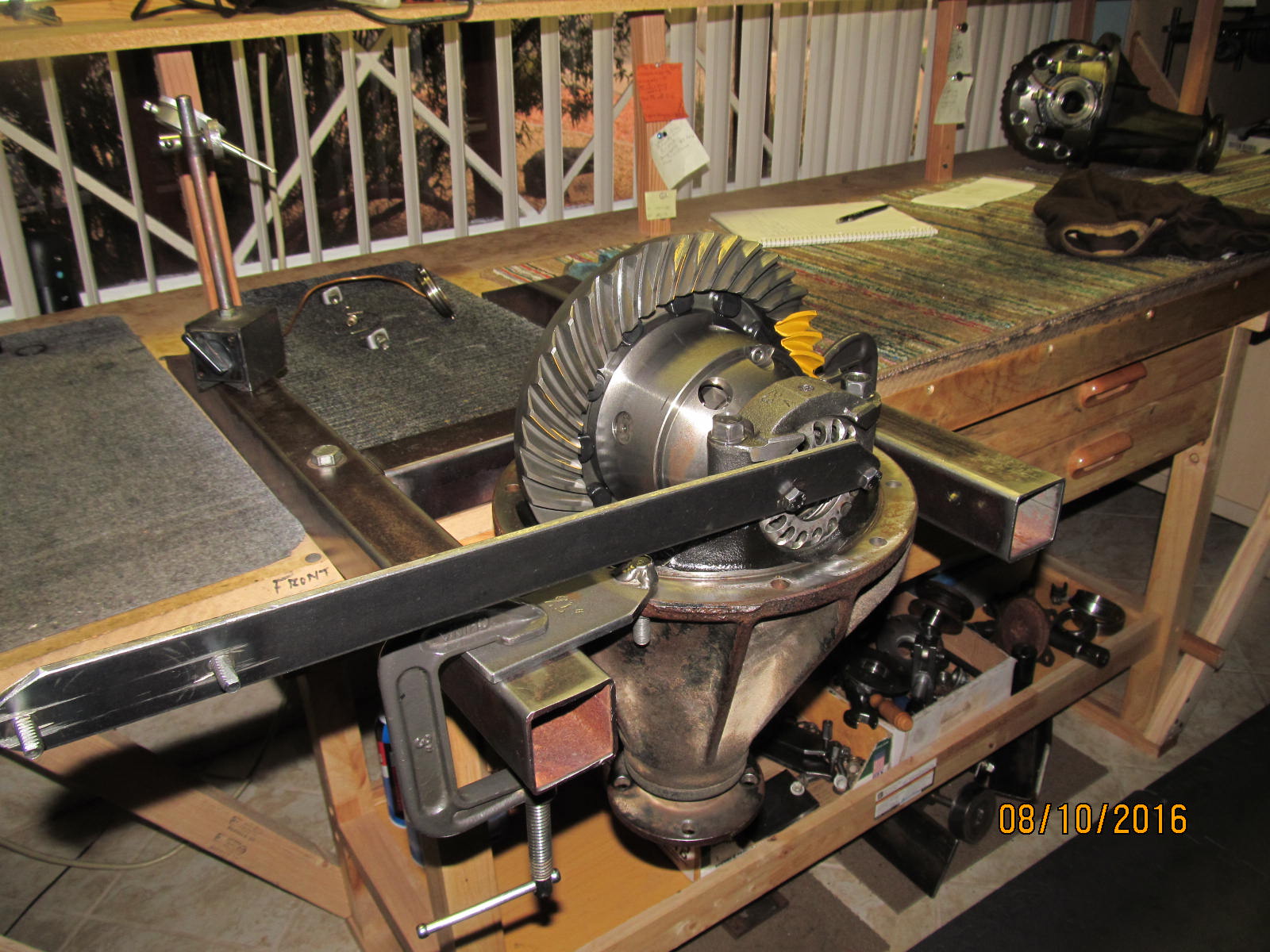

...and the really heavy rear 3rd is in the other. Both have ARBs.

|

|

|

|

|

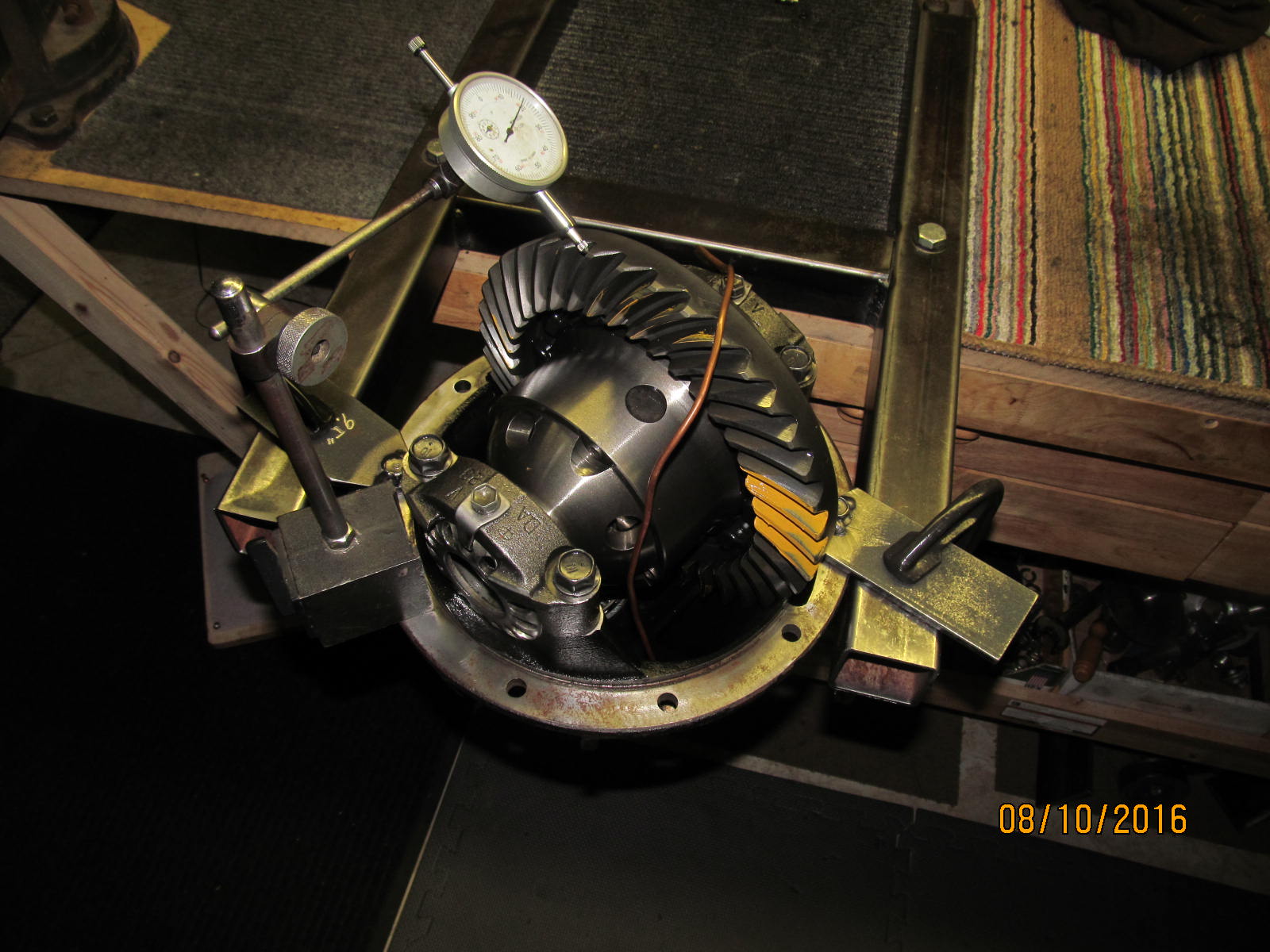

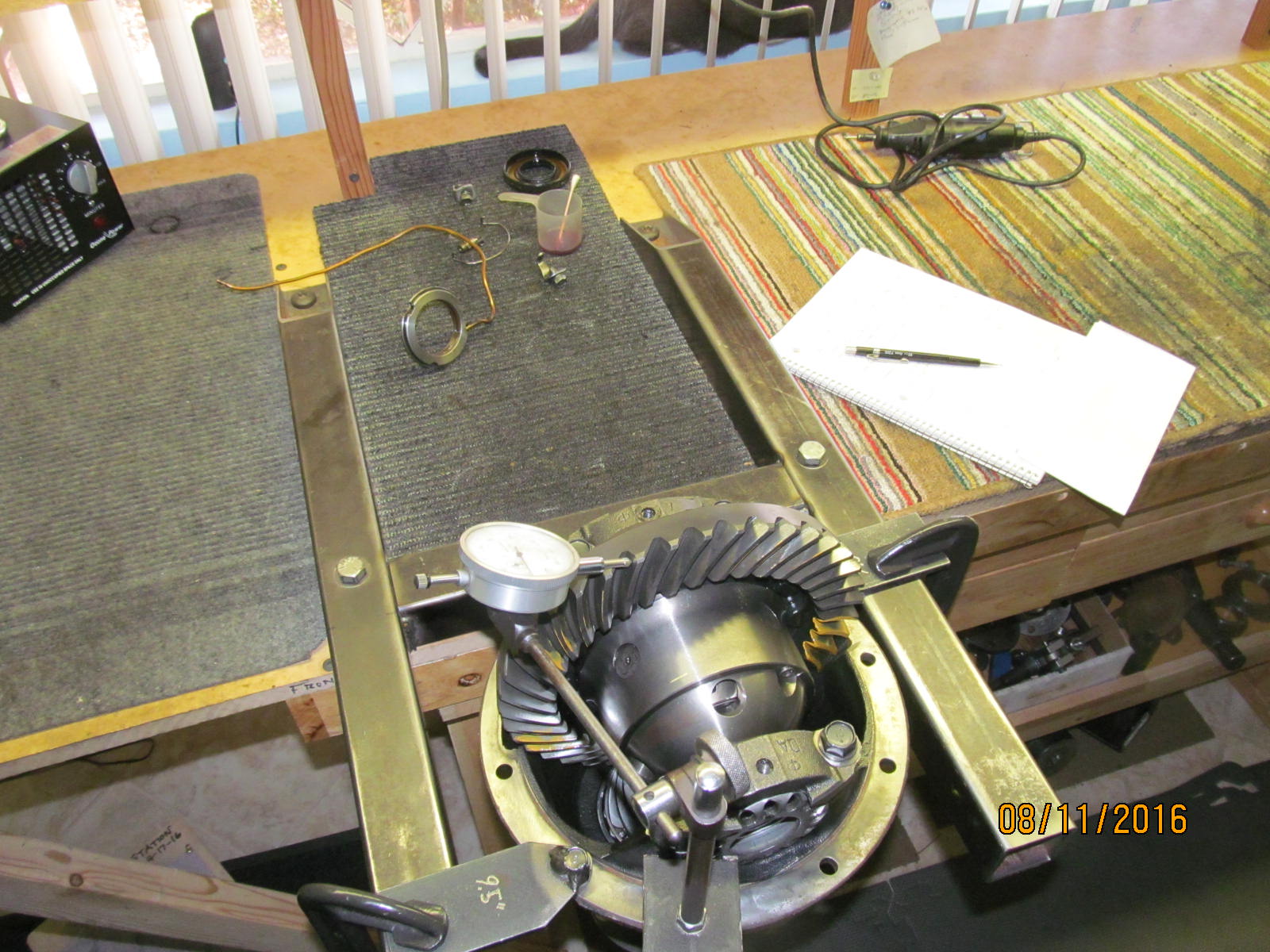

This link is for the rear 3rd and it is shown secured to the fixture for a preliminary check-up.

|

|

|

|

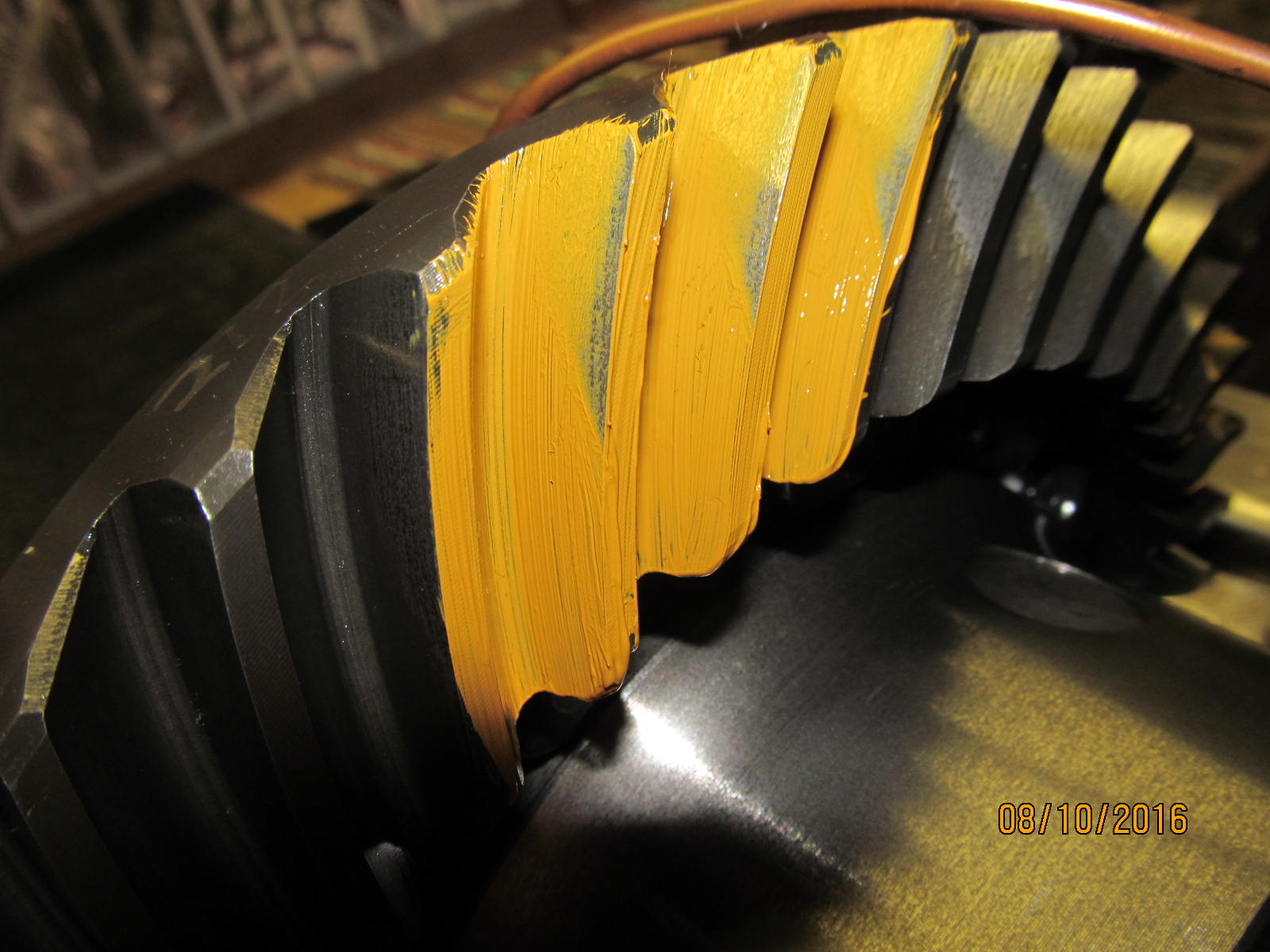

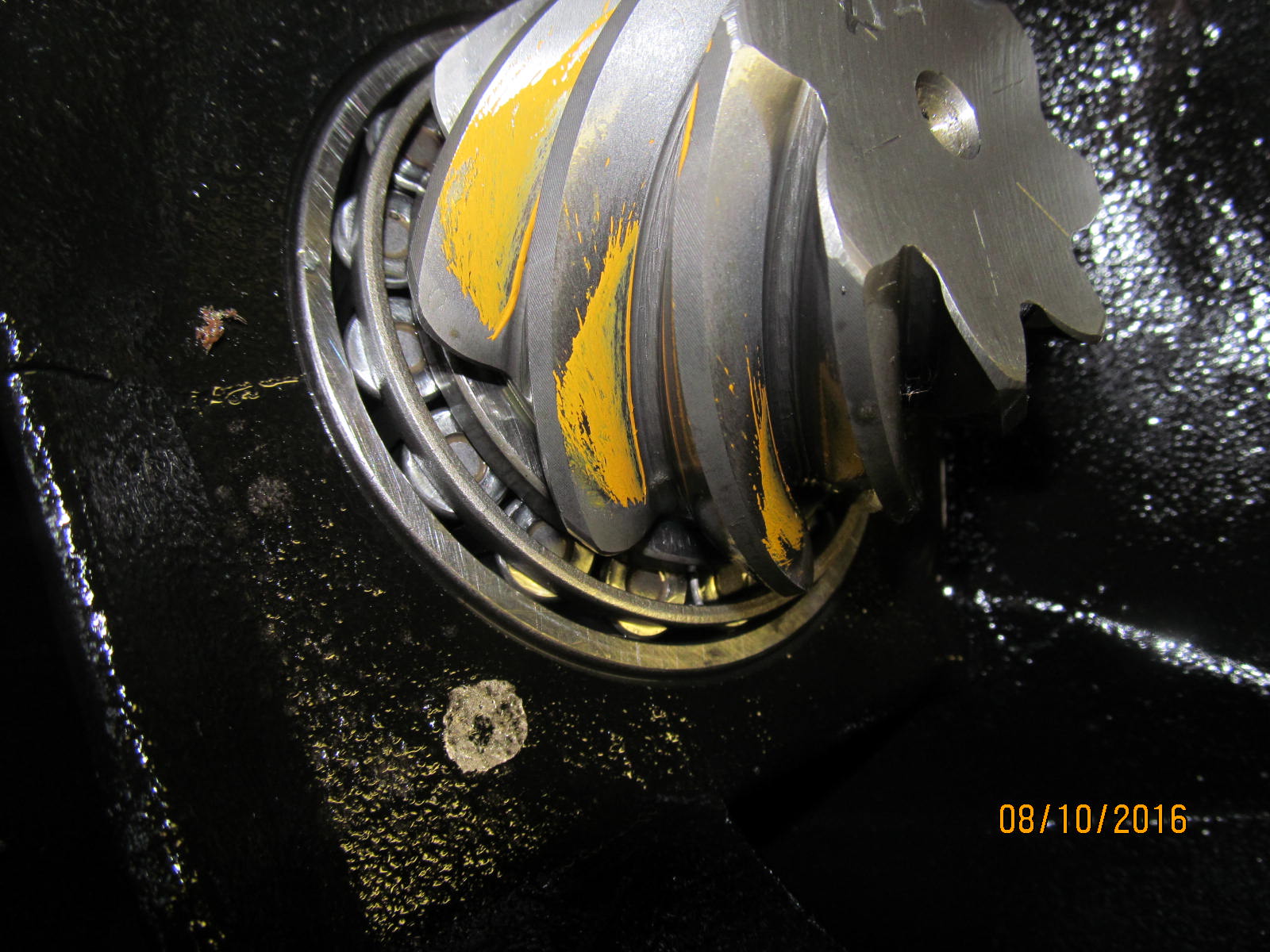

Driveside....a pattern check shows that the pinion depth is extremely shallow.

No wonder it was making terrible noises. Good thing Tim only drove it a few miles.

|

|

|

|

|

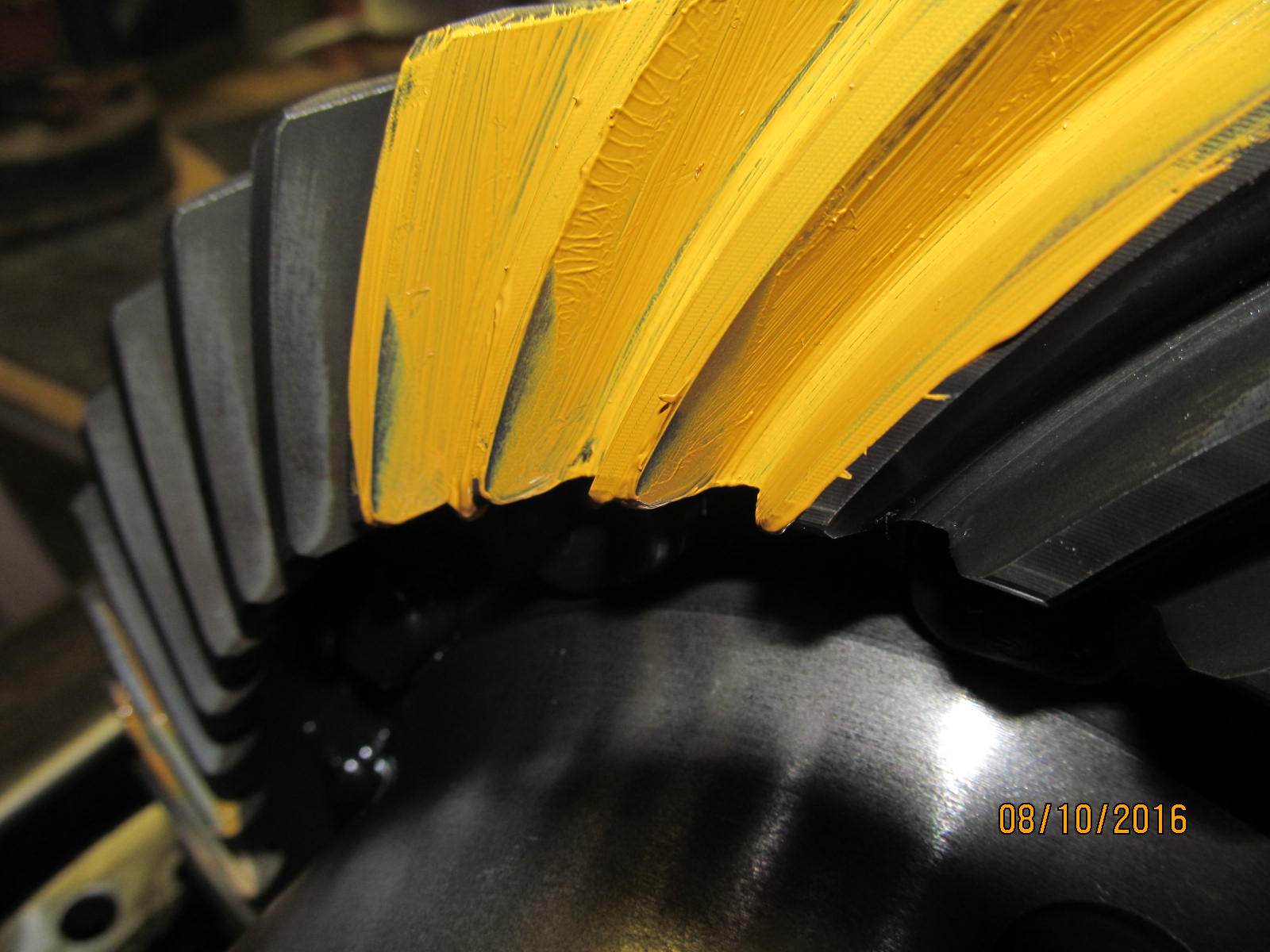

Coast reflects that.

|

|

|

|

|

Backlash was terribly wide at .019".....The carrier and pinion bearings were not unusually loose.

|

|

|

|

|

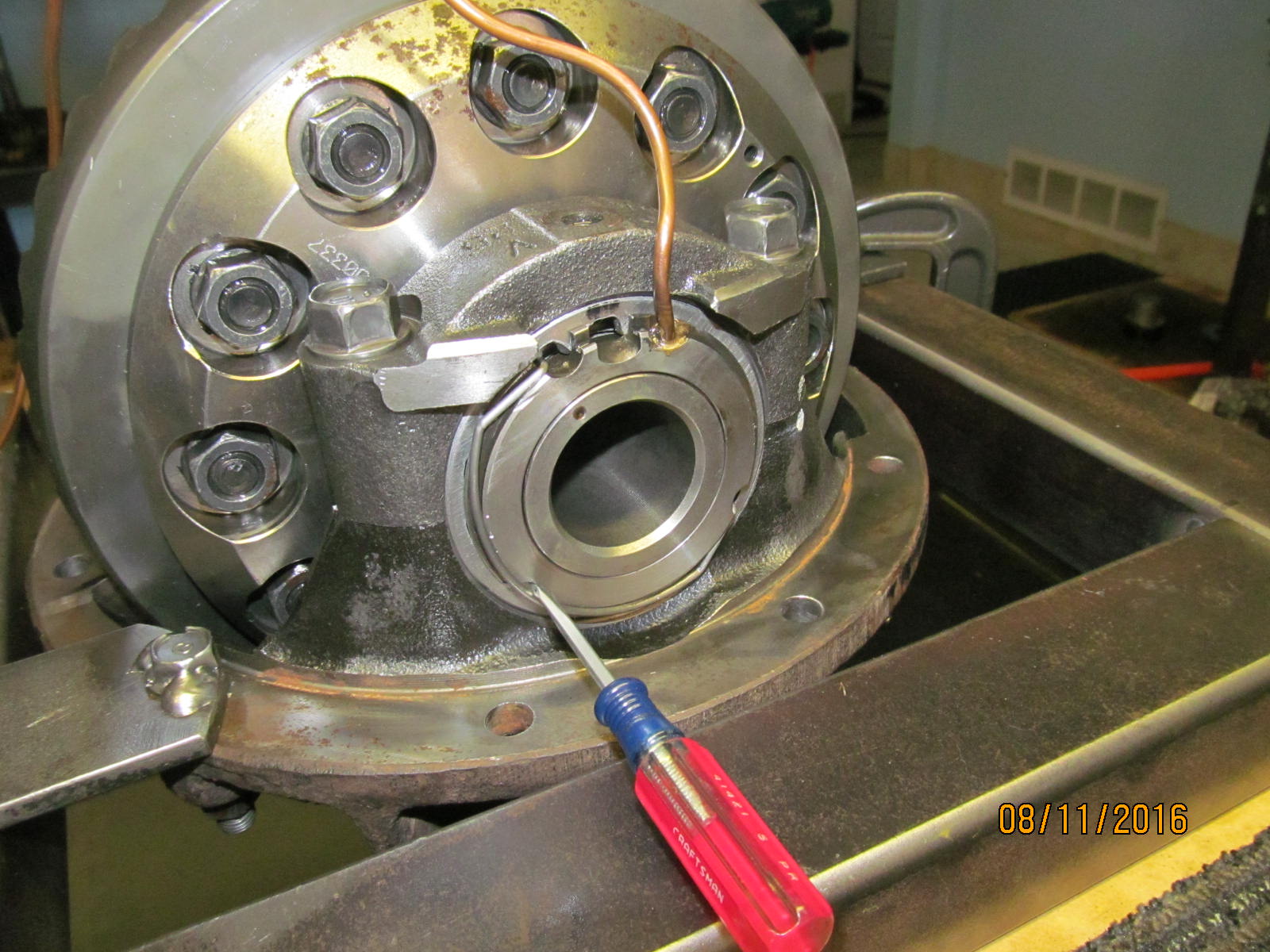

Teardown begins. I verified the arb held air pressure before removing this stuff.

|

|

|

|

|

Both adjuster wheels seemed locked up.....could not break them loose.

|

|

|

|

Finally managed to get them off. The arb wheel has raised lip damage from hits with a hammer

and flat punch of some sort.

|

|

|

|

|

A flat surface and 100 grit sandpaper will fix the high spots like new again almost.

|

|

|

|

Some grooves in the arb journal. Still held air just fine but surprised to see so much wear.

Thought it was a newish arb.

|

|

|

|

There was rust/corrosion in both of the wheel threads and that is why they seemed locked up and would not turn.

A wire brush managed to clean them out like brand new almost. Shown above is after the brush was used

but before the debri was flushed out.

|

|

|

|

|

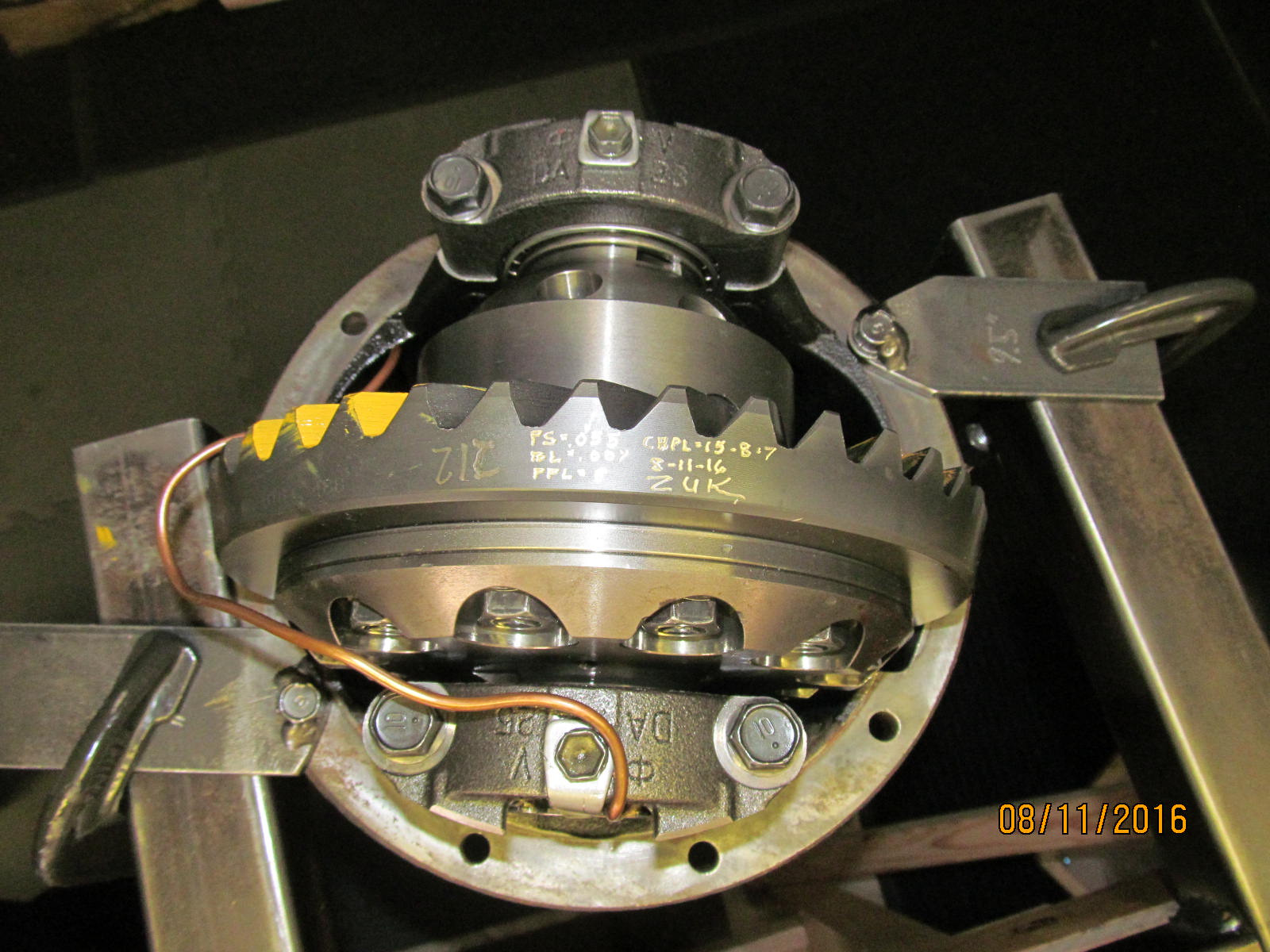

Verified they were all at 81 ft/lb minimum and they were.

|

|

|

|

|

Even the drive side of the pinion shows the extreme shallowness that the ring gear experienced.

|

|

|

|

|

,,,,,,,,,,,,,,,,

|

|

|

|

|

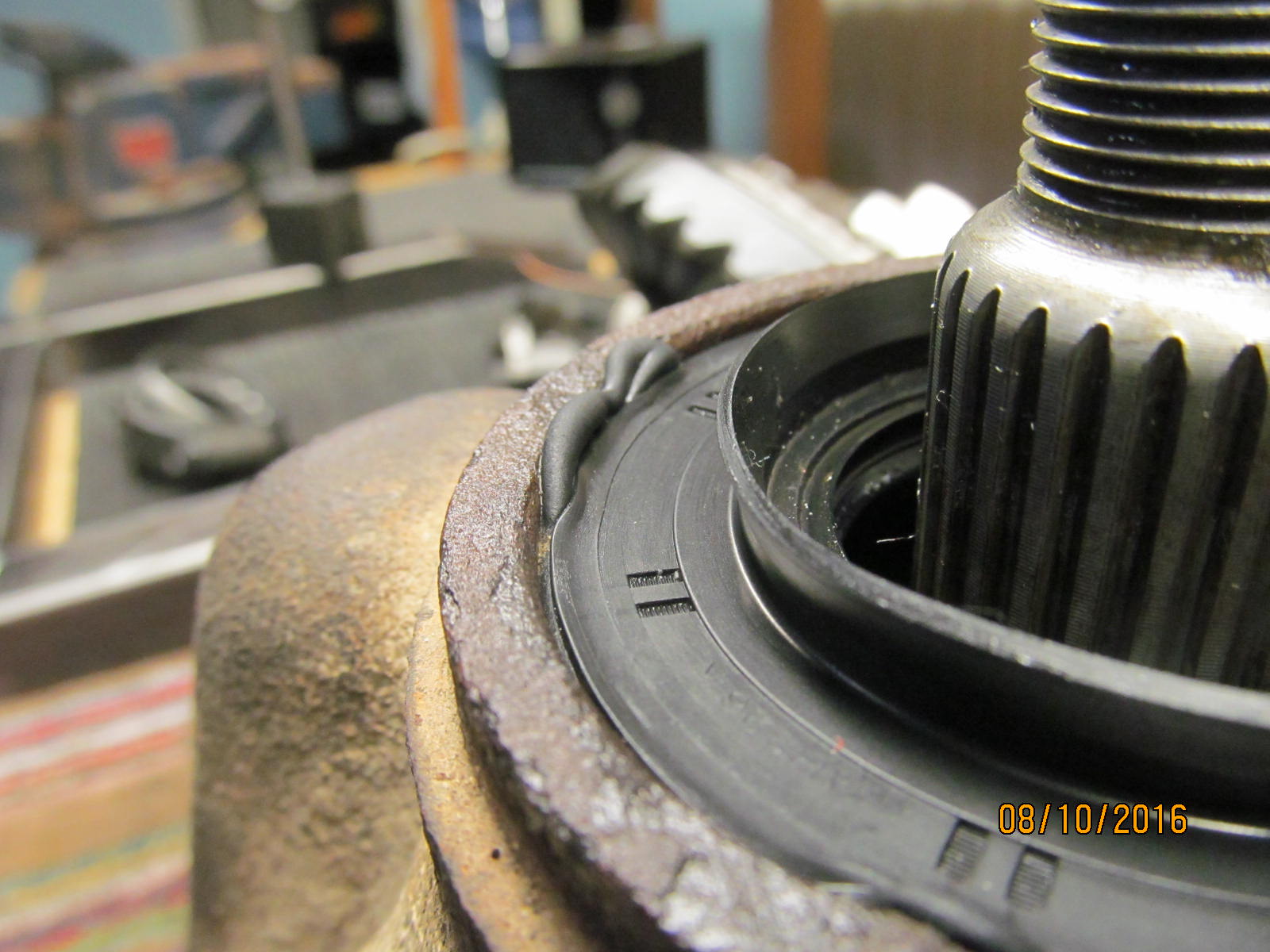

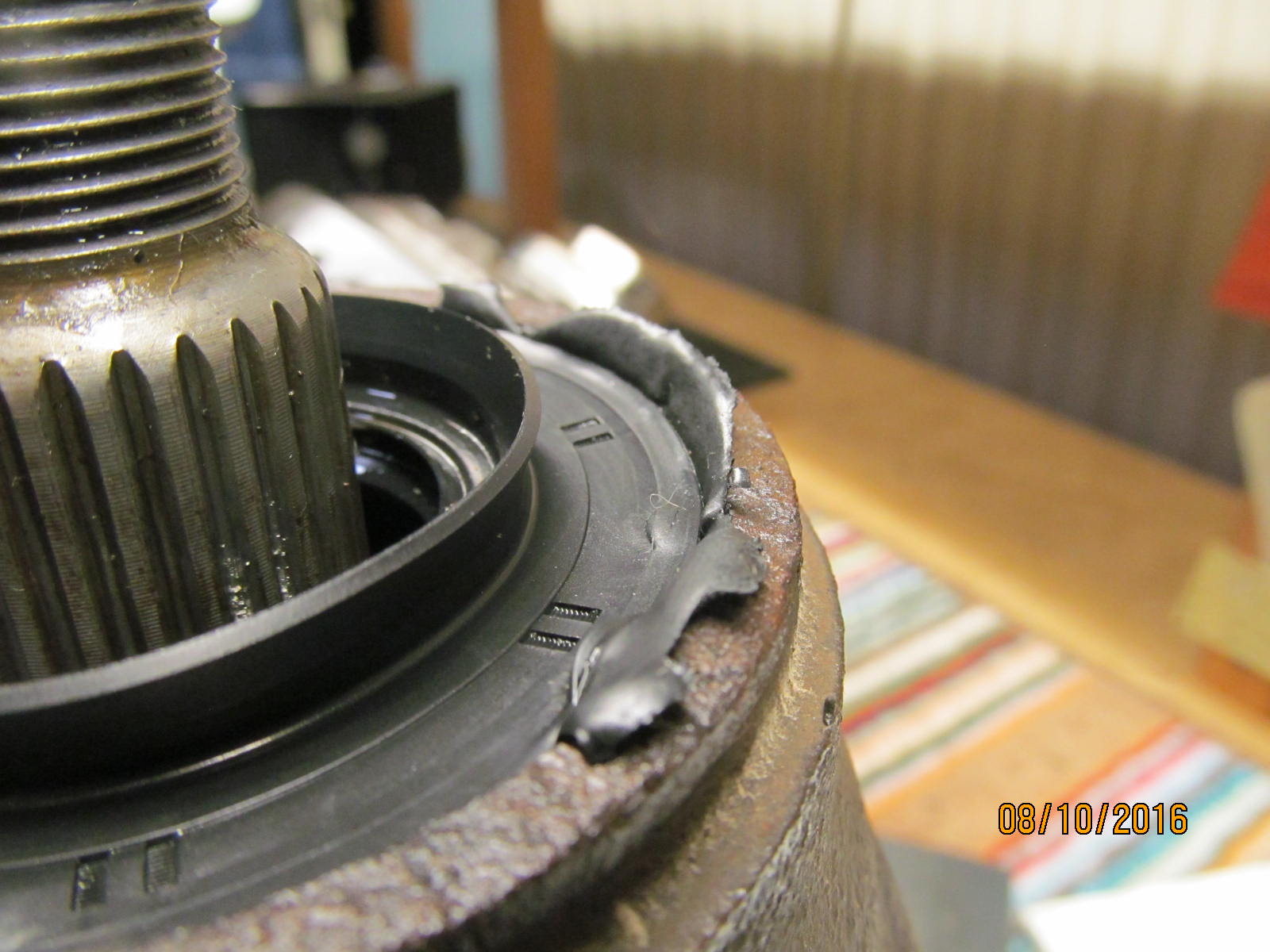

Flange was removed....a small groove here.

|

|

|

|

|

The seal has some corner issues.....interesting.

|

|

|

|

|

,,,,,,,,,,,,,,,,,,,,,

|

|

|

|

|

Pushing the pinion out now.

|

|

|

|

|

All looks ok here....some streaking marks on the new rollers but that could be contamination in the gear oil too.

|

|

|

|

|

The races look a little more "used" or older but can't be 100% sure.

|

|

|

|

|

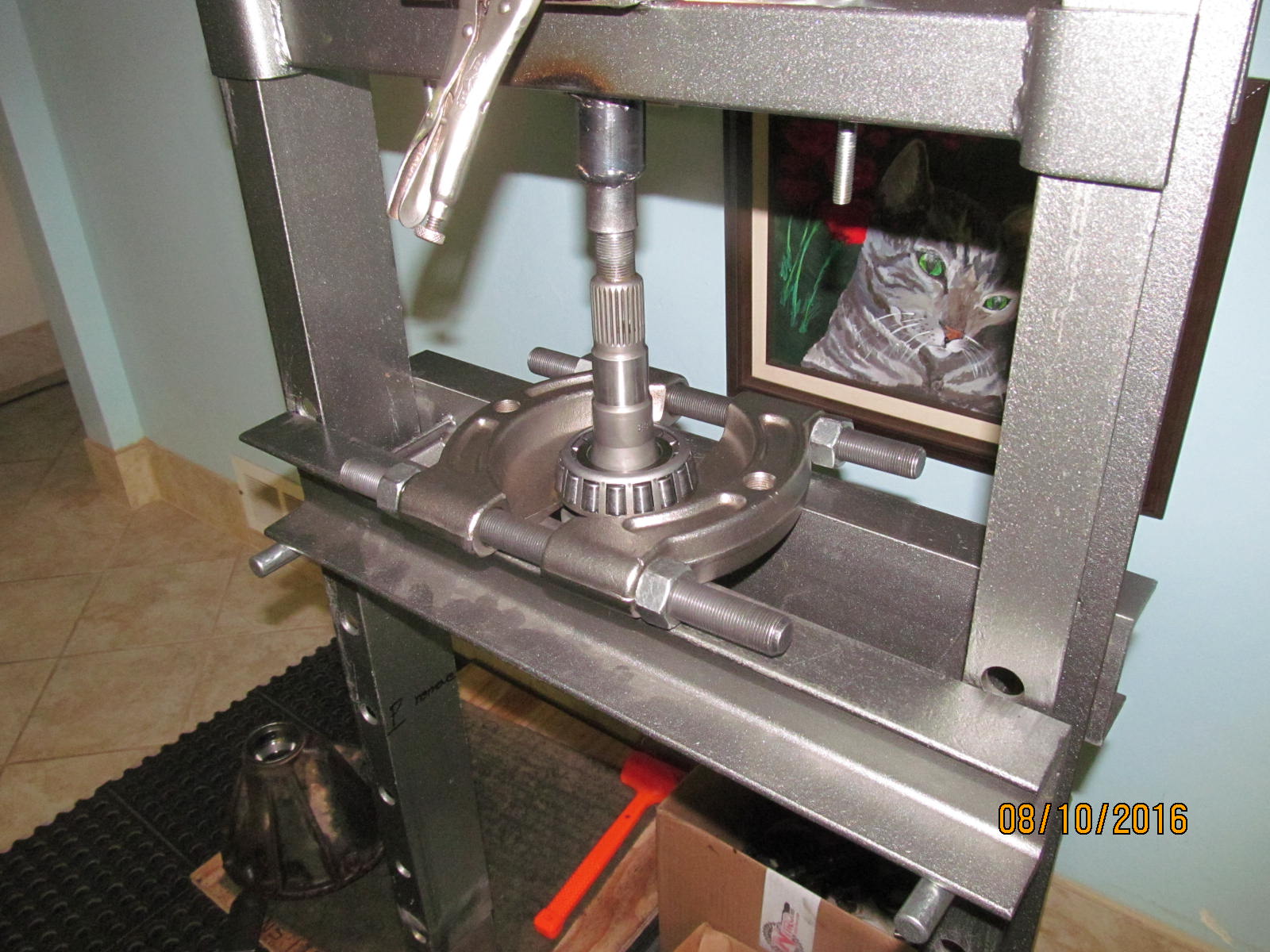

Removing the pinion bearing.....

|

|

|

|

|

....and NO pinion depth spacer found.

|

|

|

|

|

Going to try .0595" for the 1st pinion shim check.

|

|

|

|

|

Pressing it back on with the Harborfreight 12 ton.

|

|

|

|

|

Loadings up the pinion assembly into the diff carrier.

|

|

|

|

Notice how clean and spotless the 4 bolts are here? Guess I should have taken a "before pic"

because they were loaded up with carbon chunks and what appeared to be loctite.

|

|

|

|

|

The ring gear was now making full contact in this corner....guess that's why the shop had .019" backlash.

|

|

|

|

Nothing that 5 seconds with a flapper wheel couldn't fix in no time...

After this clearancing, the carrier would fit just fine and backlash could be set to spec.

|

|

|

|

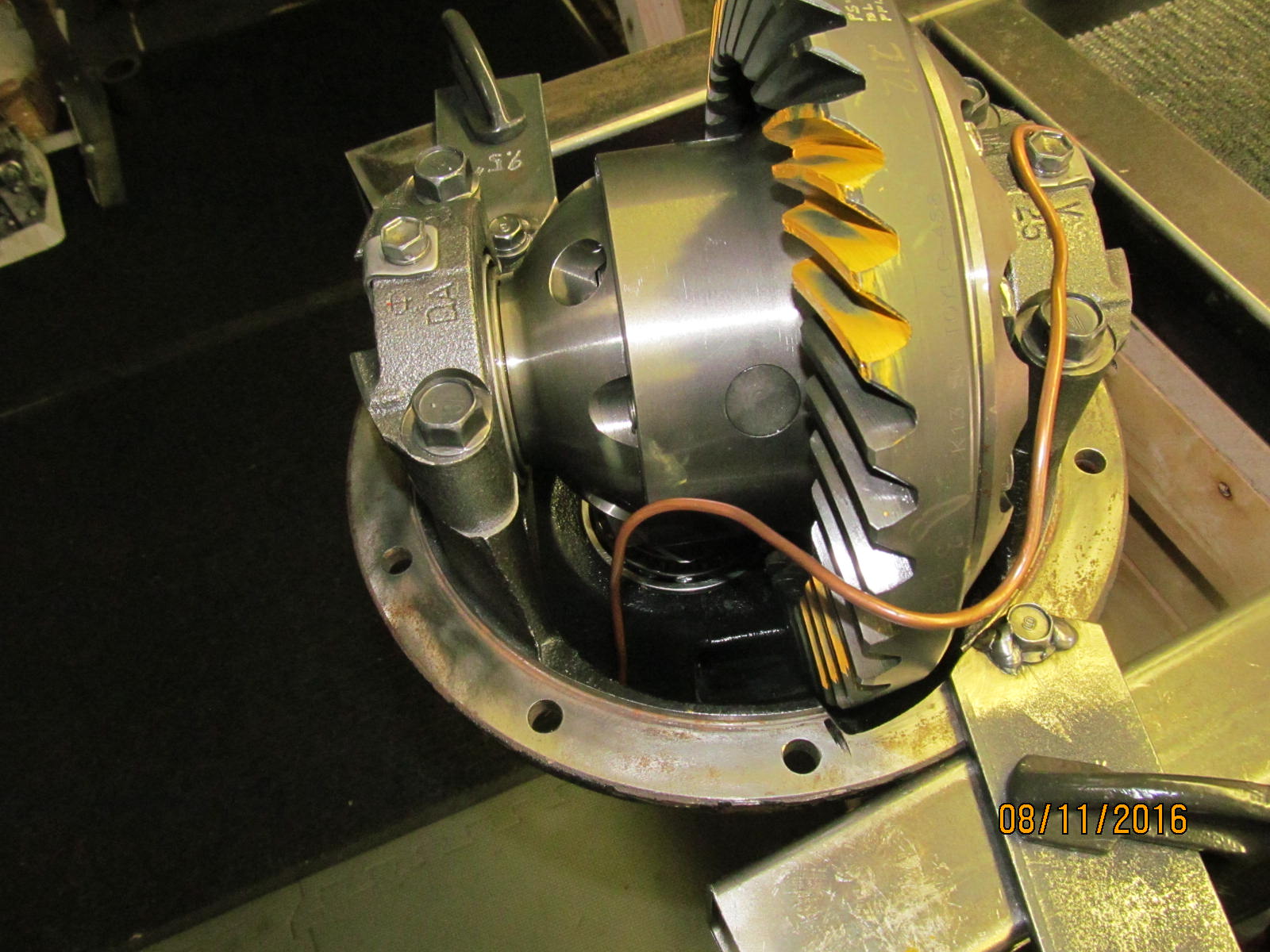

1st real pattern check and now the pattern has nice placement from toe to heel

but it's a little too deep (face to flank) even for my tastes.

|

|

|

|

|

Coast. I know from past experience if I go down to .055 that it will be right where I want it.

|

|

|

|

Skipping some repetitive pics, the pinion shim was changed to .055" and a new crush sleeve is employed.

A new pinion seal is ready to go on.

|

|

|

|

|

Gear oil is lightly applied to the related surfaces.

|

|

|

|

|

The new sleeve was crushed until a light 8 in/lb was recorded.

|

|

|

|

|

DING!! and this end is complete.

|

|

|

|

The case is re-installed and a total preload check is made...good....right at 15 in/lb.

That means my carrier bearing preload is 15 - 8 = 7 in/lb.

|

|

|

|

|

That's what I like to see....a slight deep condition and very centered at that.

|

|

|

|

|

Coast....also very centered for good balance. Looks like a ufo.....proof that they do exist.

|

|

|

|

|

The drive on the pinion says perfect! This gearset will have maximum strength.

|

|

|

|

|

................

|

|

|

|

|

A final check on bearing cap torque.....70 ft/lb on all 4.

|

|

|

|

|

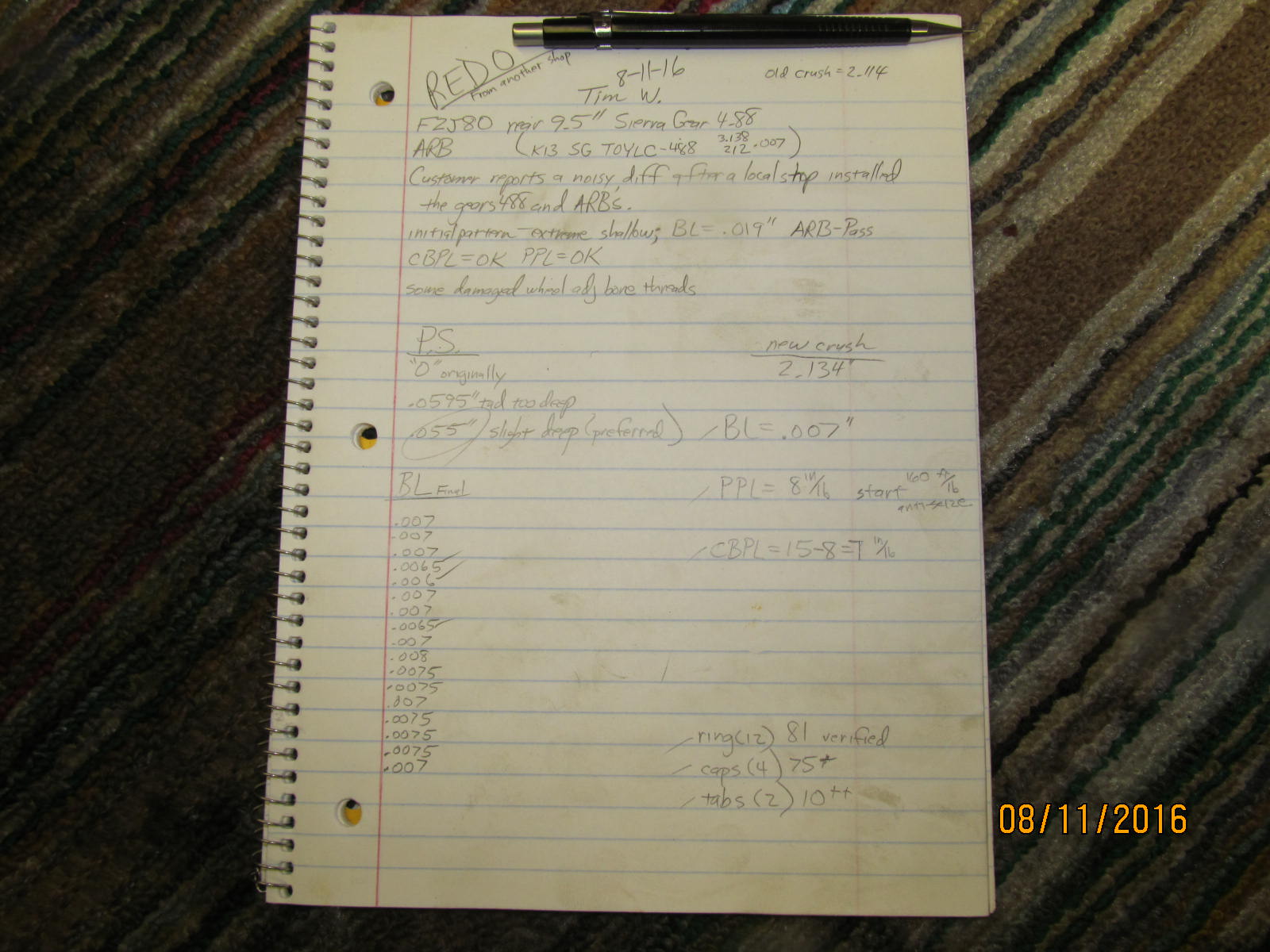

Backlash is recorded on every other tooth as shown in the notes at the end.

|

|

|

|

|

ARB seal housing assembly is in place and the retaining clip is installed as shown.

|

|

|

|

|

10+ ft/lb

|

|

|

|

|

Air check.....100 psi pass.

|

|

|

|

|

;;;;;;;

|

|

|

|

|

;;;;;;;;

|

|

|

|

|

;;;;;;;;;;

|

|

|

|

|

Final notes.

|

|

|

|

|

Boxing it up in the same double box.

|

|

|

|

|

Shielding the floor of the box with a conveniently sized Nitro box stuffed with packing materials inside.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|